- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Single Pulse Energy:

-

120J

-

Pulse Width:

-

0.1-20MS

-

Wavelength:

-

1080nm

-

Focal Spot Diameter:

-

0.3-3mm, 0.1-20ms fiber optic

-

Dimensions:

-

1240*620*1060mm

-

Weight (KG):

-

280 KG

-

Laser power:

-

1000W/1500W/2000w/3000w

-

Fiber length:

-

Standard 10M maximum support 15M

-

Way of working:

-

Continuous/modulation

-

Speed range:

-

0-120mm/s

-

Welding thinkness:

-

0.5-3mm

-

Welding gap requirements:

-

≤0.5mm

-

Cooling water:

-

Industrial therm ostatic water tank

-

Working temperature:

-

15-35℃

-

Working humidity:

-

<70% no condensation

-

Certification:

-

ce

Quick Details

-

Max. Output Power:

-

1000-3000w

-

Usage:

-

laser welding and cleaning

-

Laser Source Brand:

-

Raycus/Reci/IPG/JPT/Max

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Single Pulse Energy:

-

120J

-

Pulse Width:

-

0.1-20MS

-

Wavelength:

-

1080nm

-

Focal Spot Diameter:

-

0.3-3mm, 0.1-20ms fiber optic

-

Dimensions:

-

1240*620*1060mm

-

Weight (KG):

-

280 KG

-

Laser power:

-

1000W/1500W/2000w/3000w

-

Fiber length:

-

Standard 10M maximum support 15M

-

Way of working:

-

Continuous/modulation

-

Speed range:

-

0-120mm/s

-

Welding thinkness:

-

0.5-3mm

-

Welding gap requirements:

-

≤0.5mm

-

Cooling water:

-

Industrial therm ostatic water tank

-

Working temperature:

-

15-35℃

-

Working humidity:

-

<70% no condensation

-

Certification:

-

ce

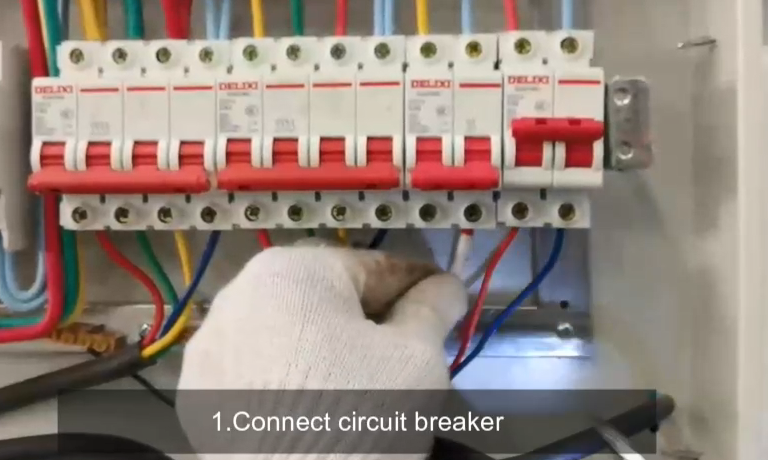

How to use the Three In One Fiber Laser Welder : https://youtu.be/QcZZQUGU6m4

1. Unpack and check if the machine is safe.

We already paid the sea shipping insurance in CIF, if it is broken, call the insurance company to get compensation please.

2.Check whether all the parts are included

If any part is missing, contact our sales please, will send you again.

3.Check the operation video and manuals

Follow the video or manuels to start the machine

4.If need help, contact service team

Our sales service can answer your questions online, help you start the machine.

B Removal paint of metal surface

C stains cleaning on the surface

D Surface coating cleaning

E Pretreatment of welding surface cleaning

F Stone surface cleaning

G Rubber mold residue cleaning

Application of Portable 3-in1 Laser Metal Welder

-

Fiber laser cleaning head has a good cleaning effect on iron, carbon steel plate, stainless steel plate, mold steel gear, aluminum plate, paint layer and other materials. The laser cleaning mode can clean the oxide layer, remove the paint on the surface; clean the surface oil, stains and dirt; clean the rubber mold residue. Meet the requirements for equipment cleaning in the shipbuilding industry, auto parts, rubber molds, machine tools, environmental protection industries and other fields

-

Fiber laser welding head is suitable for stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys. It can also be used for a variety of welding between different materials, such as: copper - brass, titanium - molybdenum, titanium - gold, nickel - copper and so on. Meet the welding needs of kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, craft gifts, home furnishing and other industries.

welding

Cleaning

Fiber laser cleaning and welding machineThe laser cleaning and welding machine can not only clean the metal surface contaminants, but also weld and combine various metal materials.

It is a multi-functional laser equipment. Equipped with Ruida system, it has two modes of cleaning and welding, which can be flexibly switched.

Specification of Portable 3-in1 Laser Metal Welder

Comparison with traditional methods

|

Comparison

|

Laser Cleaning

|

Chemical Cleaning

|

Mechanical Grinding

|

Dry ice cleaning

|

|

Washing Method

|

non-contact cleaning

|

contact cleaning

|

Abrasive contact cleaning

|

non-contact cleaning

|

|

Harm to base material

|

None

|

Yes

|

Yes

|

None

|

|

Washing Efficiency

|

High

|

Low

|

Low

|

Mid.

|

|

Consumable

|

Power

|

Chemical Detergent

|

Abrasive paper, grinder, abrasive stone

|

Dry Ice

|

|

Washing result

|

Very good, very clear

|

Medium, uneven

|

Medium, uneven

|

Good, uneven

|

|

Precision Washing

|

Accuracy controllable. High precision

|

Uncontrollable, low precision.

|

Uncontrollable, medium precision.

|

Uncontrollable, poor precision.

|

|

Safety/Environment

|

No pollution

|

Chemical pollution

|

Dust pollution

|

No pollution

|

|

Operation

|

Easy to operate, portable or automation optional.

|

Complicated process, higher technical requirement of the operator. Pollution prevention measures required.

|

Need more time & manpower. Pollution prevention measures required.

|

Easy to operate, portable or automatic.

|

|

Investment

|

High investment on machine. But no consumable, low maintenance cost

|

Low investment on machine. But expensive consumables

|

Medium investment on machine. High man-power cost.

|

Medium investment on machine. High consumable cost.

|

Au3tech Controller

12 languages are supported

The Auto wire feeding system

Accessories: