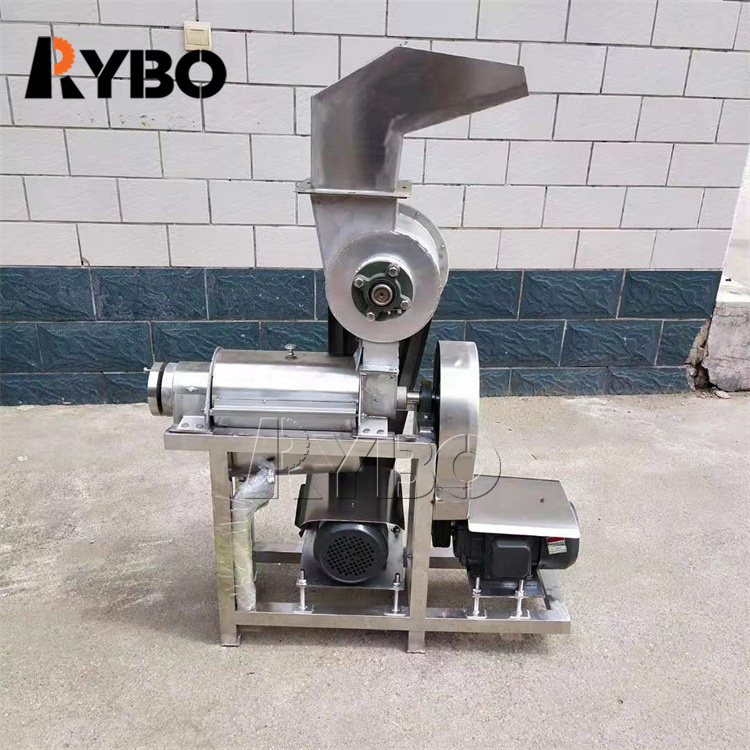

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.5KW

-

Voltage:

-

380V

-

Weight:

-

146 KG

-

Dimension(L*W*H):

-

1500*900*1500

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Juicing machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rybo

-

Processing Types:

-

fruit

-

Power:

-

1.5KW

-

Voltage:

-

380V

-

Weight:

-

146 KG

-

Dimension(L*W*H):

-

1500*900*1500

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Juicing machine

Product Description

|

Model

|

QSJ

|

|

Maximum output capacity

|

500KB/H

|

|

Filter diameter

|

0.5mm

|

|

voltage

|

380V

|

|

power

|

1.5KW

|

|

weight

|

146KG

|

Features:

This machine is suitable for fruits and vegetables such as pineapples, diamonds, turtles, carp, grapes, flowers, lemons, oranges, portals, tomatoes, papayas, potatoes, grapes, ginger, etc. The Vida militia has functions such as cutting, fracturing, fruit water, and fertilizer.

1. Advanced design, composite design, and broad vision.

2. This machine is a process of crushing, crushing, fruit water and fertilizer, which can be automated through breakthroughs and video recording of fruits.

3. The conic curve video can accept large production capacity and high fruit water data.

4. Efficient, energy-saving, low noise, and pollution-free.

All components in contact with this material are taken from 304 coarse steel.

Specification

Real Case of Customers

We will make different filling production lines for customers according to the requirements of customers and the characteristics of materials.

You can check the different types of filling machines as below according to

viscosity & fluidity of your material and capacity of your containers.

The Complete Line

We Can Supply Turnkey Project From A to Z

Normally Speaking, The whole complete oi filling production line including:

1. Bottle Feeder

2. Filling Machine

3. Capping Machine

4. Coding Machine

5. Light Checker

6. Labeling Machine

7. Carton Sealing Machine

Some machines can also be increased to the production line according to customer requirements, such as Foil Sealer, Carton Packer,Palletizers , etc.

2. Filling Machine

3. Capping Machine

4. Coding Machine

5. Light Checker

6. Labeling Machine

7. Carton Sealing Machine

Some machines can also be increased to the production line according to customer requirements, such as Foil Sealer, Carton Packer,Palletizers , etc.

Hot Searches