- Product Details

- {{item.text}}

Quick Details

-

Max. cutting force:

-

12 ton

-

Stroke adjustment:

-

5-75mm

-

Distance between upper and lower board:

-

65-140mm

-

Arm width:

-

350*450mm

-

Oil capacity (L):

-

38

-

Voltage:

-

220V/380V

-

Material:

-

Non-metal

-

Key words:

-

Shoe Machine Industry

-

Weight:

-

400kg

-

Cutting table:

-

400*800mm

Quick Details

-

Weight (KG):

-

380

-

Place of Origin:

-

Jiangsu, China

-

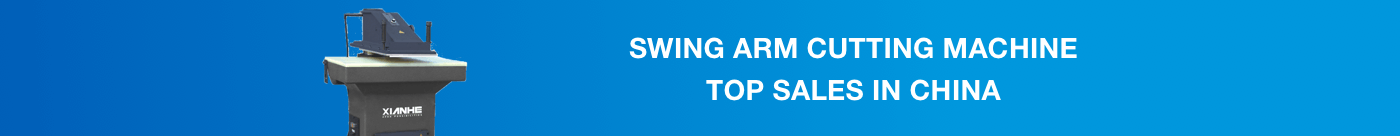

Brand Name:

-

Xianhe

-

Max. cutting force:

-

12 ton

-

Stroke adjustment:

-

5-75mm

-

Distance between upper and lower board:

-

65-140mm

-

Arm width:

-

350*450mm

-

Oil capacity (L):

-

38

-

Voltage:

-

220V/380V

-

Material:

-

Non-metal

-

Key words:

-

Shoe Machine Industry

-

Weight:

-

400kg

-

Cutting table:

-

400*800mm

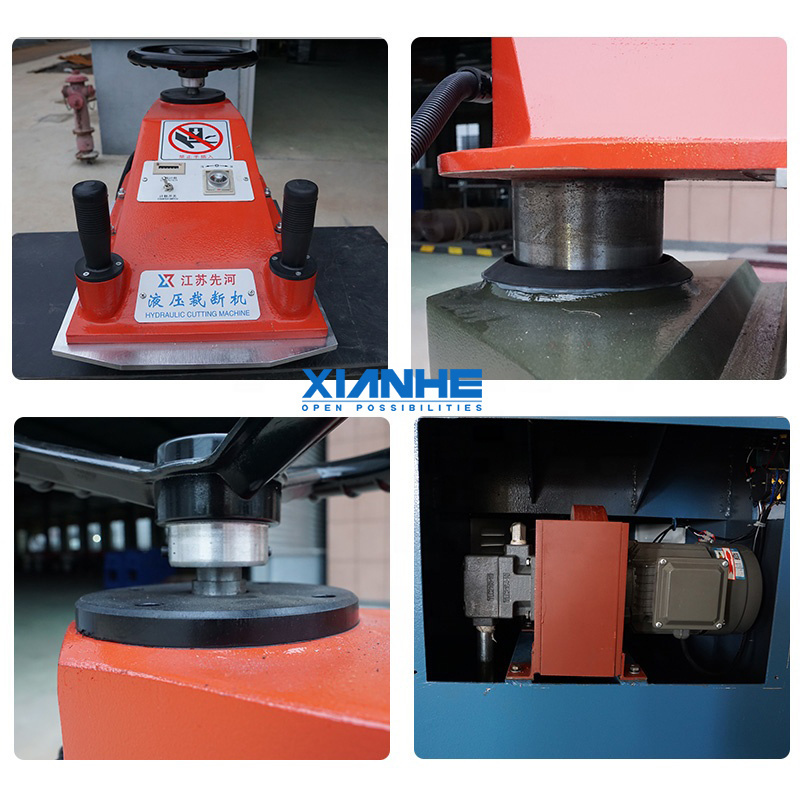

Products Description

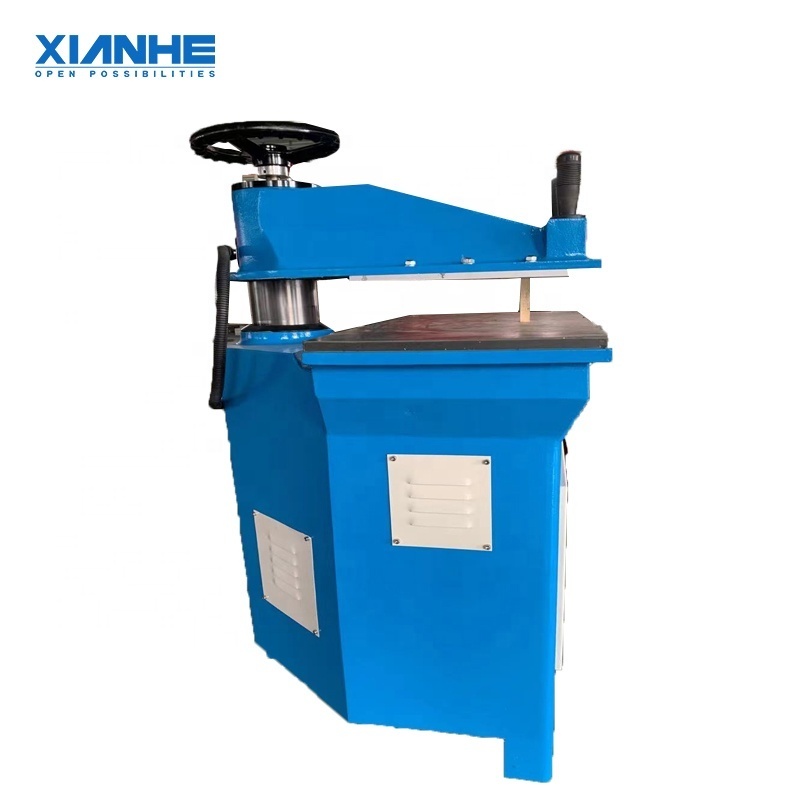

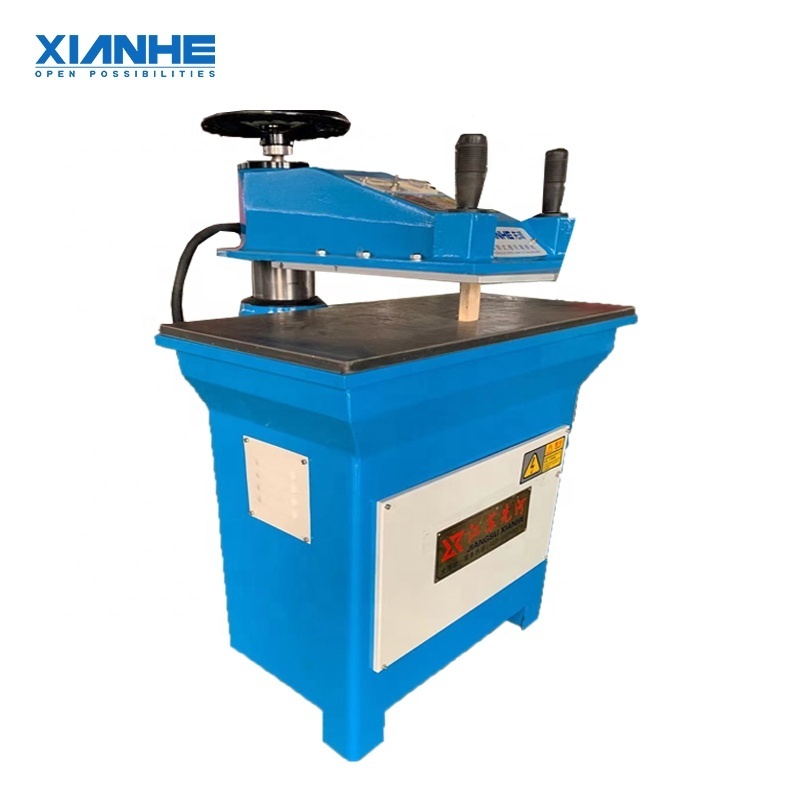

Hydraulic swing arm cutting machine/clicker press/die cutting machine:

Our machine's die cutting range is huge of uses and applications across manufacturing industry, known as clicking press or clicker press.

These machines are safe and easy to operate with the operator having only to place the material on the working table of the press, position the cutting tool on the material and press the button on the handle. The beam descends under hydraulic power to cut the required cut shape from single or multiple layers of material.

To assure maximum access and visibility, the swing arm can be easily moved to one side by the operator in order to gather cut pieces and re-position the tool for the next cut.

Did you know?

The machines are often known as ‘clicker press’ due to the historic way of cutting patterns in the shoe industry?

Originally, leather cutting operators used to produce cut parts by using a hand held knife which they would run around a pattern or template. These patterns had a brass edging to protect the template and as the blade ran round the brass edging it produced a clicking sound. Hence the operators became known as ‘clickers’. With the development of swing arm presses to do this job, the machines became known as clicker press or clicking press. The term remains in use to today.

Features

* Cut materials that are soft or semi-rigid

* Cut materials in single or multiple layers

* Fast, quiet, easy to operate

* Swing beam (arm) allows full access and visibility

* Use all standard tool types – strip steel, wood form, forged steel

* Low friction swing beam (arm) Varying tool heights can be used without adjustment

* Double acting hydraulic cylinder

* Simple daylight adjustment

* Quiet, vibration free operation

* Safe, twin button operation

* Complete with high grade polypropylene cutting board, hydraulic oil and operating manual

Our machine's die cutting range is huge of uses and applications across manufacturing industry, known as clicking press or clicker press.

These machines are safe and easy to operate with the operator having only to place the material on the working table of the press, position the cutting tool on the material and press the button on the handle. The beam descends under hydraulic power to cut the required cut shape from single or multiple layers of material.

To assure maximum access and visibility, the swing arm can be easily moved to one side by the operator in order to gather cut pieces and re-position the tool for the next cut.

Did you know?

The machines are often known as ‘clicker press’ due to the historic way of cutting patterns in the shoe industry?

Originally, leather cutting operators used to produce cut parts by using a hand held knife which they would run around a pattern or template. These patterns had a brass edging to protect the template and as the blade ran round the brass edging it produced a clicking sound. Hence the operators became known as ‘clickers’. With the development of swing arm presses to do this job, the machines became known as clicker press or clicking press. The term remains in use to today.

Features

* Cut materials that are soft or semi-rigid

* Cut materials in single or multiple layers

* Fast, quiet, easy to operate

* Swing beam (arm) allows full access and visibility

* Use all standard tool types – strip steel, wood form, forged steel

* Low friction swing beam (arm) Varying tool heights can be used without adjustment

* Double acting hydraulic cylinder

* Simple daylight adjustment

* Quiet, vibration free operation

* Safe, twin button operation

* Complete with high grade polypropylene cutting board, hydraulic oil and operating manual

Detailed Images

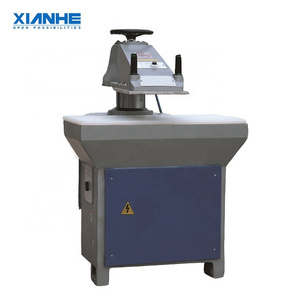

Product Paramenters

|

Model

|

SW/C-120

|

SW/C-140

|

SW/C-160

|

SW/C-200

|

|

Cutting Force

|

12T

|

14T

|

16T

|

20T

|

|

Stroke

|

5-75mm

|

5-75mm

|

5-75mm

|

5-100mm

|

|

Distance between upper & lower board

|

50-120mm

|

50-120mm

|

50-140mm

|

65-150mm

|

|

Working Table

|

400*800mm

|

400*900mm

|

410*900mm

|

500*1000mm

|

|

Upper Board

|

350*450mm

|

350*450mm

|

350*500mm

|

350*550mm

|

|

Power

|

0.75kW

|

0.75kW

|

1.1kW

|

1.5kW

|

|

Voltage/Hz

|

380V/220V

50Hz/60Hz

|

380V/220V

50Hz/60Hz

|

380V/220V

50Hz/60Hz

|

380V/220V

50Hz/60Hz

|

|

Weight

|

380kg

|

400kg

|

470kg

|

620kg

|

|

Machine Dimension

|

800*650*1240mm

|

900*650*1240mm

|

900*760*1330mm

|

1000*950*1400mm

|

|

Package Dimension

|

880*845*1420mm

|

980*845*1420mm

|

980*960*1570mm

|

1080*1030*1600mm

|

Why Choose Us

Packing & Delivery

Related Products

Contact US

Hot Searches