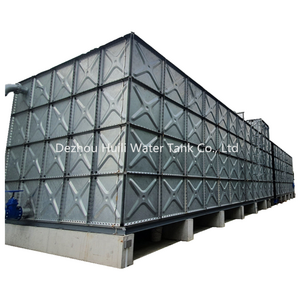

Galvanized Steel Water Tank is punched by Q235A into 1220mm*1220mm or 1000mm*1000mm and 1000mm*500mm, 500mm*500mm standard plates,drilled around, after HDG treatment, and assembled at site. When combined, the gap between two standard plates is sealed by silicon pad, and connected by bolts.

Water capacity varies from 1.0 cubic meter to 1000 cubic meters, height may reach as great as 5 meters. Inflow, outflow tubes as well as return tube's diameter and place is decided by the designer, passages of at least 7000mm is needed around the tank.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

steel frame, 304 316 stainless steel

-

Weight:

-

none

-

Size:

-

customized

-

Power:

-

none

-

Weight (KG):

-

35 kg

-

Product name:

-

Stainless steel pressed panel hot water tank 20m3

-

Production method:

-

Hot Pressed Moulding

-

Panel size::

-

2x1m, 1.5x1m, 1x1m, 1x0.5m, 0.5x0.5m

-

Panel thickness:

-

1.5-5mm

-

Connection type:

-

Bolted/welded type

-

Certificate:

-

ISO 9001:2008, WRAS

-

Installation guide:

-

Installation vedio or technician on site

-

Working life:

-

more than 25 years

-

MOQ:

-

1 cubic meter

Quick Details

-

Core Components:

-

stainless steel panels

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Success

-

Material:

-

steel frame, 304 316 stainless steel

-

Weight:

-

none

-

Size:

-

customized

-

Power:

-

none

-

Weight (KG):

-

35 kg

-

Product name:

-

Stainless steel pressed panel hot water tank 20m3

-

Production method:

-

Hot Pressed Moulding

-

Panel size::

-

2x1m, 1.5x1m, 1x1m, 1x0.5m, 0.5x0.5m

-

Panel thickness:

-

1.5-5mm

-

Connection type:

-

Bolted/welded type

-

Certificate:

-

ISO 9001:2008, WRAS

-

Installation guide:

-

Installation vedio or technician on site

-

Working life:

-

more than 25 years

-

MOQ:

-

1 cubic meter

Product Description

HDG galvanized steel water storage tank

Reinforcement Method :

All tanks are internally braced with angle stays to endure the rigidity of the tank when filled with the water. The Top panel is supported by top panel support, which shall be made of stainless steel grade 304 or 316 material according to requirement.

Materials :

The sectional panel tank shall consist of 4' x 4' or 1 meter x 1 meter panel manufactured from 1.5mm to 5.0mm thickness according to requirement.

Application:

T

he construction water storing, the regulating tank, heating system's inflation water tank, the condensate tank as well as the

building construction, the geological prospecting, the industry, the defense project and so on temporarily store water tank.

building construction, the geological prospecting, the industry, the defense project and so on temporarily store water tank.

Details Images

Tank Structure

|

HDG water tank includes four parts:

|

|

|

|

(1) Panels

|

Bottom panel, wall panel, roof panel and manhole

|

|

|

(2) Internal parts

|

Internal ladder, tiepiece rod, support, flanges and rubber

|

|

|

(3) External parts

|

External ladder, angle iron, tiepiece board, bolts and nuts

|

|

|

(4) U-steel base

|

surface treatment can be painted or hot dipped galvanized or stainless steel

|

|

Specification

|

Product Name

|

Popular sectional galvanized steel water storage tank

|

|

|

|

|

||||

|

Material

|

Hot galvanized steel

|

|

|

|

|

||||

|

Panel Size

|

2x1m

|

1.5x1m

|

1x1m

|

1x0.5m

|

1.22x1.22m

|

||||

|

Panel Thickness

|

1.5-5mm

|

1.5-5mm

|

1.5-5mm

|

1.5-5mm

|

1.5-5mm

|

||||

|

Connection type

|

Bolts & nuts

|

|

|

|

|

||||

|

Foundation

|

Concrete foundation and U-steel bottom base

|

|

|

|

|

||||

|

Accessories

|

Leaking stoppage, tiepiece, support, flange, sealing gasket, rubber strip, screws, tiepiece plant, ladder, washer, fasten clamp,water gauge.

|

|

|

|

|

||||

|

Application

|

as the storage equipment for reclaimed water, fire water; widely used in mining, residential buildings, hotels, office buildings,schools, restaurants and other public facilities.

|

|

|

|

|

||||

|

Water Tank

|

Bottom

|

1st layer side panel

|

2nd layer

|

3rd layer side panel

|

4th layer side panel

|

5th layer side panel

|

Top panel

|

|

Height (mm)

|

panel

|

/

|

side panel

|

/

|

/

|

/

|

/

|

|

1000

|

3

|

3

|

/

|

/

|

/

|

/

|

2

|

|

1500

|

3

|

3

|

3

|

/

|

/

|

/

|

2

|

|

2000

|

3

|

3

|

3

|

/

|

/

|

/

|

2

|

|

2500

|

4

|

4

|

3

|

3

|

/

|

/

|

2

|

|

3000

|

4

|

4

|

3

|

3

|

/

|

/

|

2

|

|

3500

|

4

|

4

|

3

|

3

|

3

|

/

|

2

|

|

4000

|

5

|

5

|

4

|

3

|

3

|

/

|

2

|

|

5000

|

5

|

5

|

5

|

4

|

4

|

3

|

2

|

Accessories

Installation

With the right equipment and personnel, you can quickly get through assembling your tank. For a successful GRP Tank Installation,you need at least five workers, one of whom should be qualified.

Here is a brief installation guide:

➽ After getting a permit to install on a particular site, ensure you have all the required equipment.

➽ They should be free of damage to prevent a substandard finish.

➽ Check that the area of installation is level.

➽ Assemble the beams horizontally on the foundation or steel tower to form the skid base.

➽ Install the bottom panel carefully on the skid base.

➽ Install the side panels. Once the side panels are in place, you can put up the panel partitions.

➽ The panels should be joined using bolts and nuts, as per the manufacturer's recommendations.

➽ Install the tie rods and stainless steel partitions to support the roof.

➽ Assemble the top cover/roof.

➽ Install internal and external stainless steel ladders.

➽ Tie all stainless steel nuts and bolts with a washer.

After completing the installation and getting approval from a consultant, carry out a water leak test. Connect a temporary water supply pipe and let the water stay in for at least 24 hours. Make sure you have enough air vents. If there are any leakages after the test period, rectify and seek approval.

➽ After getting a permit to install on a particular site, ensure you have all the required equipment.

➽ They should be free of damage to prevent a substandard finish.

➽ Check that the area of installation is level.

➽ Assemble the beams horizontally on the foundation or steel tower to form the skid base.

➽ Install the bottom panel carefully on the skid base.

➽ Install the side panels. Once the side panels are in place, you can put up the panel partitions.

➽ The panels should be joined using bolts and nuts, as per the manufacturer's recommendations.

➽ Install the tie rods and stainless steel partitions to support the roof.

➽ Assemble the top cover/roof.

➽ Install internal and external stainless steel ladders.

➽ Tie all stainless steel nuts and bolts with a washer.

After completing the installation and getting approval from a consultant, carry out a water leak test. Connect a temporary water supply pipe and let the water stay in for at least 24 hours. Make sure you have enough air vents. If there are any leakages after the test period, rectify and seek approval.

For installation, we can provide installation guide: installation video or installation assistance on site by our engineers.If parts are damaged within the quality insurance period because of quality fault, we will change the damaged parts free ofcharge.

Packing & Delivery

☞Packing:

Solid Seaworthy plywood Box Package with Steel Frame.(Save space as much as possible for container loading.)

☞Delivery:

☀Freight on Board Delivery (FOB):

If you choose to get your tank through Freight On Board Delivery, the shipping charges will vary depending on the contract. The terms of FOB delivery indicate whether we or you, the buyer, is responsible for the shipping cost and up to what point the cargo is in the hands of either party. If we take up delivery charges, then the buyer takes responsibility for the GRP Tank upon arrival at the cargo destination and pays for transportation cost after that.

☀Cost Insurance and Freight Delivery (CIF):

With Cost Insurance and Freight Delivery, we are solely in charge of your GRP tank delivery, until the time it arrives at your desired destination. This means that we will cover the transportation cost from the company to the port, ensure safe loading and take care of customs clearance and insurance. However, this mode of delivery might be a bit costly because you may have to pay nextra for all the resources used to cover your customs clearance and insurance. It is, however, convenient if you are pressed fortime.

☀Freight on Board Delivery (FOB):

If you choose to get your tank through Freight On Board Delivery, the shipping charges will vary depending on the contract. The terms of FOB delivery indicate whether we or you, the buyer, is responsible for the shipping cost and up to what point the cargo is in the hands of either party. If we take up delivery charges, then the buyer takes responsibility for the GRP Tank upon arrival at the cargo destination and pays for transportation cost after that.

☀Cost Insurance and Freight Delivery (CIF):

With Cost Insurance and Freight Delivery, we are solely in charge of your GRP tank delivery, until the time it arrives at your desired destination. This means that we will cover the transportation cost from the company to the port, ensure safe loading and take care of customs clearance and insurance. However, this mode of delivery might be a bit costly because you may have to pay nextra for all the resources used to cover your customs clearance and insurance. It is, however, convenient if you are pressed fortime.

For standard water tank less than 200m3, it would be 3-5 days;

For non-standard water tank and customized water tank according to client's specific requirements, it would be 7 to 15 days.

For non-standard water tank and customized water tank according to client's specific requirements, it would be 7 to 15 days.

Certifications

WRAS & TUV REPORT

Hot Searches