- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

5000*1500*1500mm

-

Weight:

-

8000 kg

-

Feeding width:

-

130-415mm

-

Marketing Type:

-

New Product 2023

-

Function:

-

Cutting Punching Bending

-

Raw material:

-

Color Steel Coil

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

400H Steel

-

Cutting type:

-

Hydraulic Cutting

-

Thickness:

-

0.3--1.0mm

-

Feature:

-

High Production Speed

-

Machinery Test Report::

-

Provided

-

Warranty of core components::

-

5 years

-

Hydraulic oil tank:

-

500L

Quick Details

-

Type:

-

Profile Rolling Machine

-

Tile Type:

-

GI/Cold Steel/Q235/Q345

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V or as required

-

Dimension(L*W*H):

-

5000*1500*1500mm

-

Weight:

-

8000 kg

-

Feeding width:

-

130-415mm

-

Marketing Type:

-

New Product 2023

-

Function:

-

Cutting Punching Bending

-

Raw material:

-

Color Steel Coil

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

400H Steel

-

Cutting type:

-

Hydraulic Cutting

-

Thickness:

-

0.3--1.0mm

-

Feature:

-

High Production Speed

-

Machinery Test Report::

-

Provided

-

Warranty of core components::

-

5 years

-

Hydraulic oil tank:

-

500L

Products Description

Specification

|

Metal Stud Profile Rolling Machine

|

value

|

|

||

|

1.Formed Material

|

GR

|

Thickness: 0.3-0.8mm

Width: 50-100mm

(Can be customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

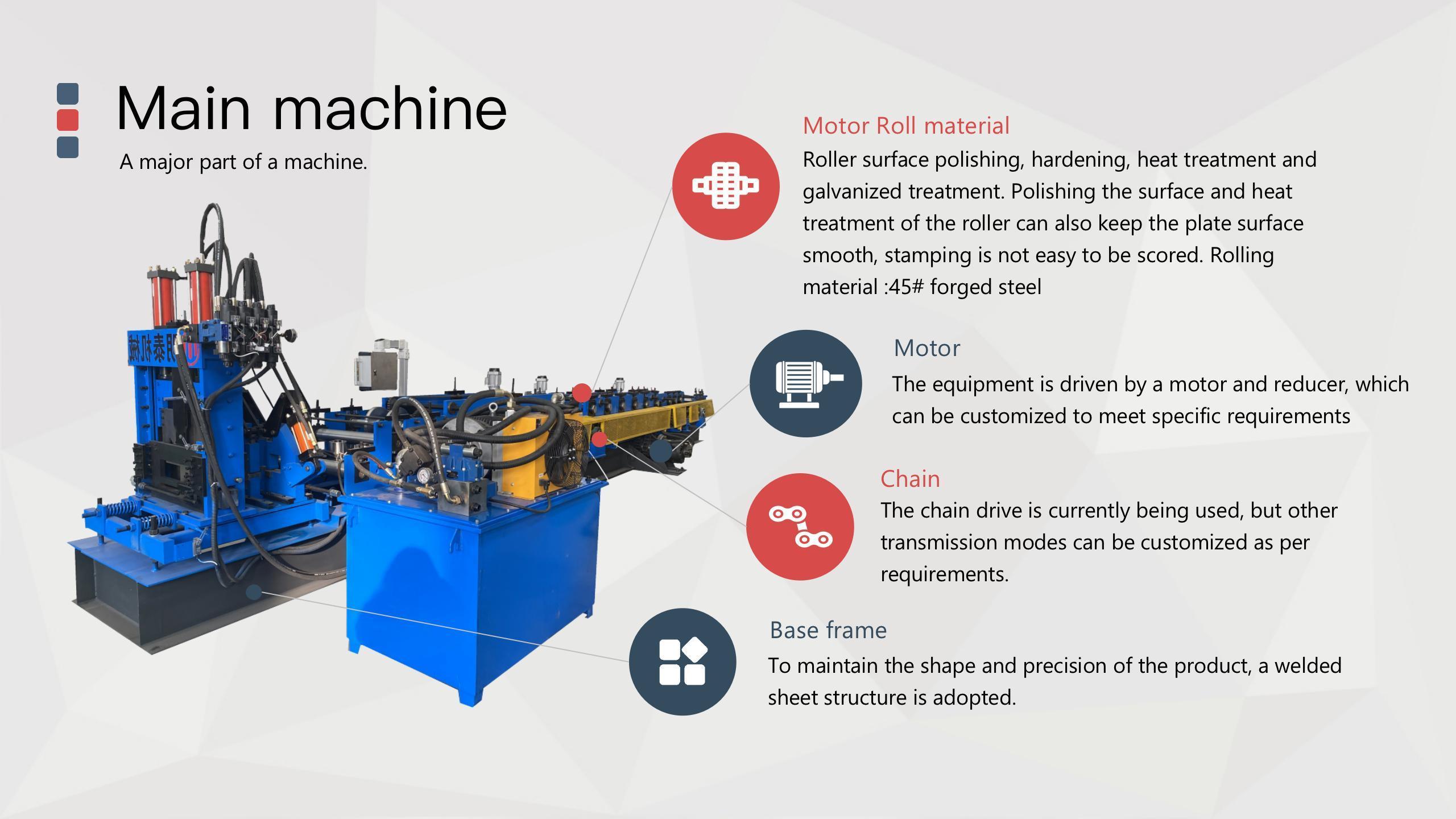

3.Main body

|

Roller station

|

13 rows (Can be customized)

|

||

|

Type

|

Diameter of shaft

|

70mm solid shaft

|

||

|

Tile Type

|

Material of rollers

|

CR12 steel, hard chrome plated on the surface

|

||

|

Production Capacity

|

Machine body frame

|

350 H steel

|

||

|

Place of Origin

|

Drive

|

Gearbox transmission

|

||

|

|

Dimension(L*W*H)

|

5000*1500*1500(Can be customized)

|

||

|

Brand Name

|

Weight

|

10T

|

||

|

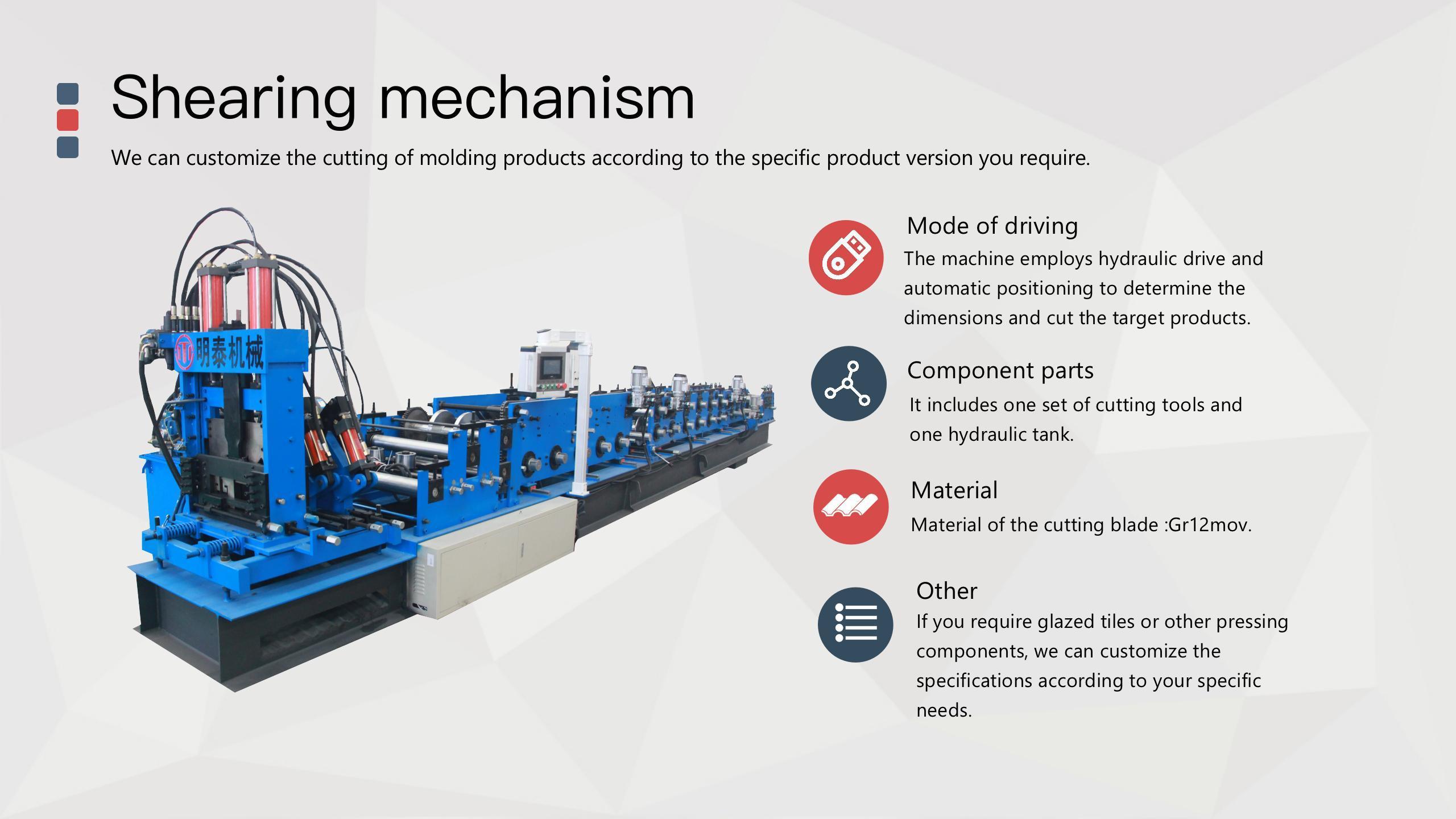

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW (Siemens brand)

|

||

|

6.Voltage

|

Hydraulic system power

|

7.5KW

|

||

|

6.Voltage

|

380V 50Hz 3Phase

|

Can be customized

|

||

|

7.Control system

|

Electric Box

|

Can be customized

|

||

|

Rolling thinckness

|

Language

|

English(multiple languages supported)

|

||

|

Feeding width

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

FAQ

Q: What types of rolling forming machines do you offer?

A: We offer a wide range of rolling forming machines, including roof panel roll forming machines, wall panel roll forming machines, decking floor roll forming machines, gutter roll forming machines, and many more.

Q: Can you customize the machines according to our specific requirements?

A: Yes, we can provide customized solutions to meet your exact needs, whether it's modifying an existing design or creating a completely new machine.

Q: What materials can your machines work with?

A: Our machines can work with a variety of materials, including steel, aluminum, zinc, and others.

Q: How long does it take to manufacture and deliver a machine?

A: We offer a wide range of rolling forming machines, including roof panel roll forming machines, wall panel roll forming machines, decking floor roll forming machines, gutter roll forming machines, and many more.

Q: Can you customize the machines according to our specific requirements?

A: Yes, we can provide customized solutions to meet your exact needs, whether it's modifying an existing design or creating a completely new machine.

Q: What materials can your machines work with?

A: Our machines can work with a variety of materials, including steel, aluminum, zinc, and others.

Q: How long does it take to manufacture and deliver a machine?

A: The lead time for manufacturing and delivery depends on the complexity of the machine and the quantity ordered. We willprovide an estimated timeline once we have all the details of your order.

Q: What is your warranty policy?

A: We provide a one-year warranty for electrical components and a two-year warranty for all other parts of our machines, covering any defects in materials or workmanship. Additionally, we offer lifetime technical support and maintenance services.

Q: What is your installation process?

A: We provide detailed installation instructions and videos, and our technical team is always available to provide support and guidance. We can also send our engineers to your site for installation and training if needed, this may incur additional costs by the buyer.

Q: What is your after-sales service?

A: We provide comprehensive after-sales service, including maintenance, repair, and replacement of parts. We also offer remote technical support and troubleshooting to ensure that your machine is always running at its best.

Q: What is your warranty policy?

A: We provide a one-year warranty for electrical components and a two-year warranty for all other parts of our machines, covering any defects in materials or workmanship. Additionally, we offer lifetime technical support and maintenance services.

Q: What is your installation process?

A: We provide detailed installation instructions and videos, and our technical team is always available to provide support and guidance. We can also send our engineers to your site for installation and training if needed, this may incur additional costs by the buyer.

Q: What is your after-sales service?

A: We provide comprehensive after-sales service, including maintenance, repair, and replacement of parts. We also offer remote technical support and troubleshooting to ensure that your machine is always running at its best.

Hot Searches