- Product Details

- {{item.text}}

Quick Details

-

Material:

-

35MnB

-

Surface Hardness:

-

HRC52-58

-

Hardness Depth:

-

8-12mm

-

Warranty:

-

1200-2400hrs

-

Color:

-

Yellow/Black

-

Processing:

-

Forging

-

Weight:

-

75KGS

-

Application:

-

Excavator undercarriage parts

-

Certification:

-

ISO9001

Quick Details

-

Year:

-

2022

-

Place of Origin:

-

Fujian, China

-

Model:

-

D5 D5B D5C D5D D5E D5G D5H D5K D5M D5N

-

Material:

-

35MnB

-

Surface Hardness:

-

HRC52-58

-

Hardness Depth:

-

8-12mm

-

Warranty:

-

1200-2400hrs

-

Color:

-

Yellow/Black

-

Processing:

-

Forging

-

Weight:

-

75KGS

-

Application:

-

Excavator undercarriage parts

-

Certification:

-

ISO9001

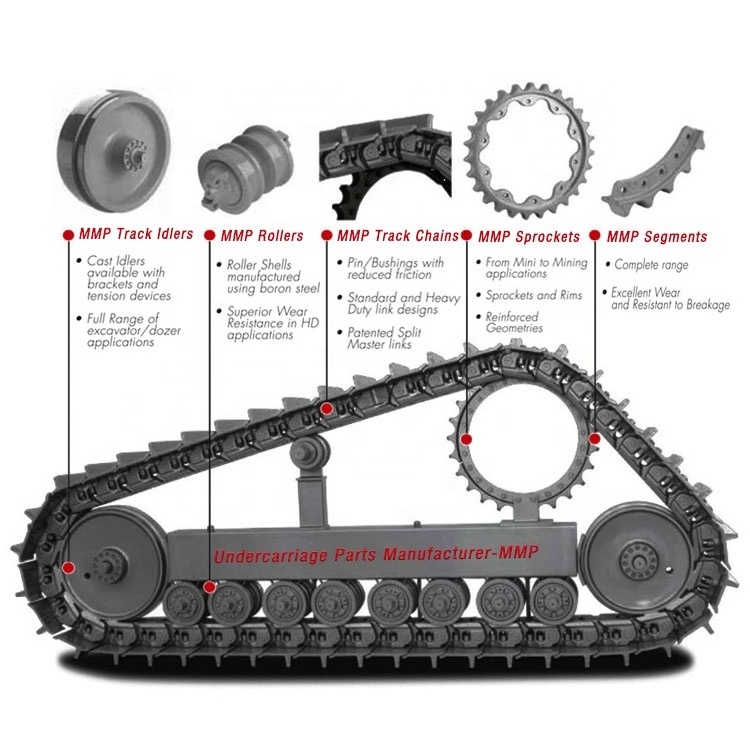

PRODUCTS DESCRIPTION

MITNIK MACHINE PARTS-MMP

Your 1st Choice in Spare Parts For Excavat

or, Bulldozer,

and Other Construction Machines

We are MITNIK MACHINE PARTS-MMP have set up a one-stop shopping platform for engineering construction machinery parts, and the products involve:

1. Excavator&bulldozer undercarriage,

2. Engaging tools(bucket teeth, bucket tip, bucket, cutting edge, end bit),

3. Engine parts (excavator&bulldozer engine parts, engineering truck engine parts etc..),

5. Dump truck parts, concrete machine parts( easy wearing parts, blades, mixer, shaft, electrical parts).

4. Hydraulic parts (hydraulic pump, hydraulic cylinder, quick couple, hydraulic track link pusher machine)

1. Excavator&bulldozer undercarriage,

2. Engaging tools(bucket teeth, bucket tip, bucket, cutting edge, end bit),

3. Engine parts (excavator&bulldozer engine parts, engineering truck engine parts etc..),

5. Dump truck parts, concrete machine parts( easy wearing parts, blades, mixer, shaft, electrical parts).

4. Hydraulic parts (hydraulic pump, hydraulic cylinder, quick couple, hydraulic track link pusher machine)

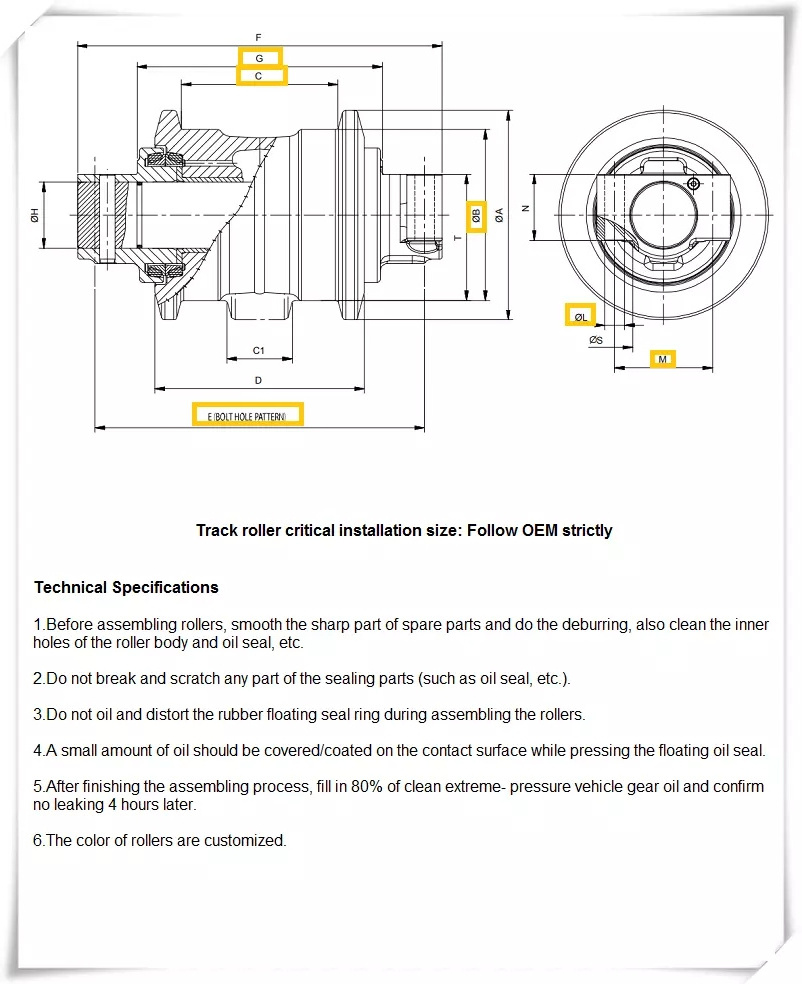

All our Parts Follow OEM Strictly Technical Specifications

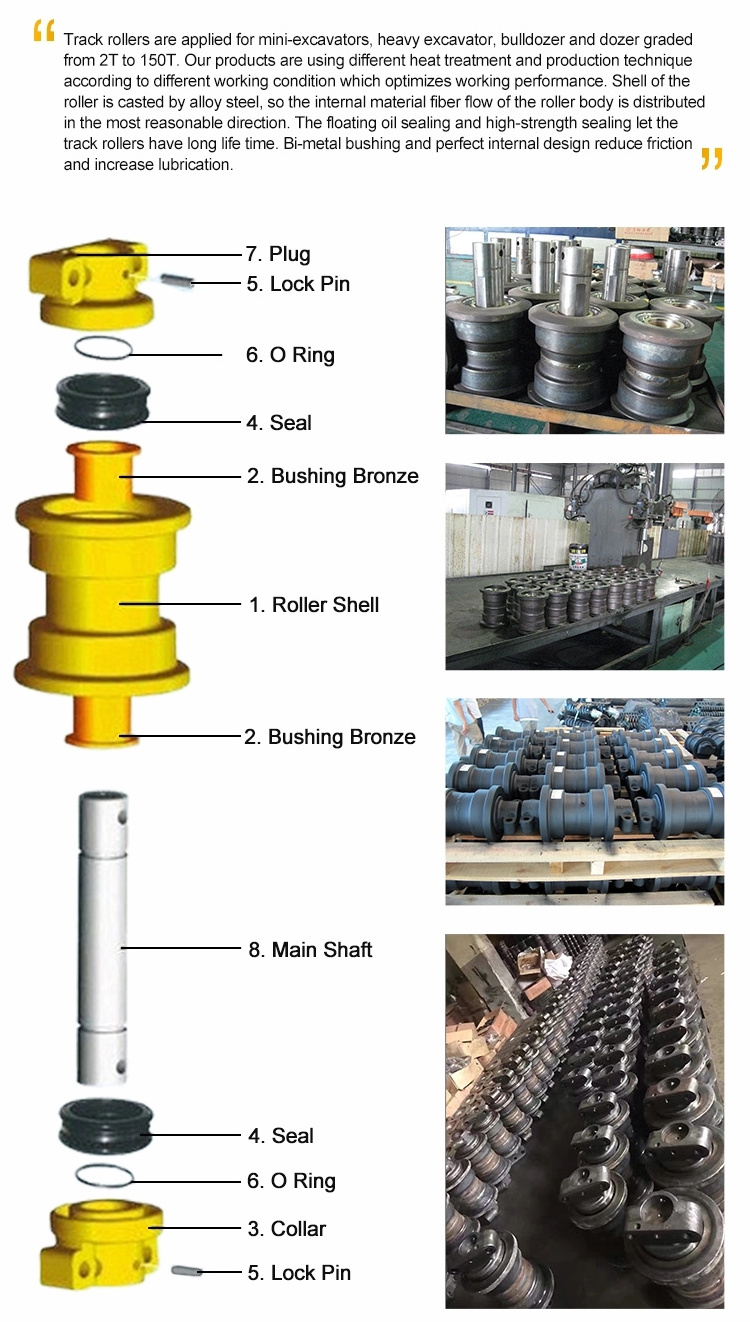

1.Before assembling rollers, smooth the sharp part of spare parts anddothe debring alsocleantheimer holes of the roller body and oil seal, etc.

2.Do not break and scratch any part of the sealing parts(such asoilseal etc))

3.Do not oil and distort the rubber floating seal ring during assembling therolles.

4.A smallamount of oil should be covered/coated on the contact surface while pressing the foating oilseal

5.Afterfinishing the assembling processflin 80% of cleanextreme- pressrevehicle gearoiland confim no leaking 4 hours later.

6.The color of rollers are customized.

|

Material

|

35MnB

|

|

Finish

|

Smooth

|

|

Colors

|

Black or yellow

|

|

Technique

|

Forging / casting

|

|

Surface Hardness

|

HRC52-58,deepth:8mm-12mm

|

|

Warranty time

|

1 year

|

|

Certification

|

ISO9001

|

|

Delivery Time

|

Within 5-17 days after contract established

|

TRACK ROLLERS

Track rollers are applied for mini excavator, heavy excavator/bulldozer and crawler crane undercarriage from 2T to 150T, MMP/MITNIK machine parts are using different heat treatment and production technique according to different working condition which optimizes working performance. The shell of track roller is casting by alloy steel, so the internal material fiber flow of the roller body is distributed in the most reasonable direction. The floating oil sealing and high-strength sealing let the track rollers have long life time. Bi-metal bushing and perfect internal design reduce friction and increase lubrication

PRODUCT SPECIFICATIONS

|

RAND

|

MOSTLY FULL UNDERCARRIAGE PARTS CAN OFFER

|

|

|

|

|

|

|

|

|

||||||||

|

BULLDOZER

|

D20

|

D30

|

D31

|

D37

|

D40

|

D41

|

D45

|

D50

|

D60

|

||||||||

|

|

D65

|

D68

|

D75

|

D80

|

D85

|

D150

|

D155

|

D275

|

D355

|

||||||||

|

|

D3C

|

D3D

|

D4C

|

D4D

|

D4H

|

D5

|

D6C

|

D6D

|

D6H

|

||||||||

|

|

D7G

|

D8K

|

D8N

|

D9N

|

D10N

|

D11N

|

|

|

|

||||||||

|

KOMATSU

|

PC30

|

PC40

|

PC45

|

PC60

|

PC75

|

PC100

|

PC120

|

PC150

|

PC200

|

||||||||

|

|

PC220

|

PC300

|

PC350

|

PC400

|

|

|

|

|

|

||||||||

|

CATERPILLAR

|

E70B

|

E110

|

E120B

|

E215

|

E235

|

E307

|

E311

|

E312

|

E322

|

||||||||

|

|

E180

|

E240

|

E200B

|

E320

|

E300

|

E300B

|

E330

|

E325

|

|

||||||||

|

HITACHI

|

EX30

|

EX40

|

EX60

|

EX100

|

EX120

|

EX200

|

EX220

|

EX270

|

EX300

|

||||||||

|

|

EX400

|

EX600

|

UH043

|

UH052

|

UH53

|

UH07

|

UH081

|

UH082

|

UH083

|

||||||||

|

FIAT-HITACHI

|

FH120

|

FH130

|

FH150

|

FH200

|

FH220

|

FH270

|

FH300

|

|

|

||||||||

|

VOLVO

|

EC55

|

EC130

|

EC150

|

EC200

|

EC210

|

EC240

|

EC290

|

EC360

|

|

||||||||

|

DAEWOO

|

DH55

|

DH130

|

DH180

|

DH200

|

DH280

|

DH300

|

DH320

|

|

|

||||||||

|

HYUNDAI

|

R60

|

R130

|

R200

|

R210

|

R220

|

R290

|

R320

|

R914

|

|

||||||||

|

KATO

|

HD250

|

HD400

|

HD450

|

HD700

|

HD770

|

HD820

|

HD1250

|

|

|

||||||||

|

KOBELCO

|

SK40

|

SK60

|

SK100

|

SK120

|

SK200

|

SK220

|

SK04-2

|

SK07

|

|

||||||||

|

|

SK07N2

|

SK09

|

SK12

|

SK14

|

SK300

|

SK310

|

SK400

|

|

|

||||||||

|

JCB

|

JS70

|

JS75

|

JS110

|

JS130

|

JS160

|

JS180

|

JS200

|

JS220

|

|

||||||||

|

|

JS240

|

JS260

|

JS300

|

JS330

|

|

|

|

|

|

||||||||

|

SUMITOMO

|

SH70

|

SH100

|

SH120

|

SH160

|

SH200

|

SH260

|

SH265

|

SH280

|

SH300

|

||||||||

|

|

SH340

|

LS2650

|

LS2800

|

LS3400

|

LS4300

|

|

|

|

|

||||||||

|

|

MX8

|

SE200

|

SE210

|

SE280

|

MX292

|

SE350

|

|

|

|

||||||||

|

MITSUBISHI

|

MS110

|

MS120

|

MS140

|

MS180

|

|

|

|

|

|

||||||||

Please verify part number prior to order.

Thanks for viewing our listings. Please click "Ask A Question", or call us if you have a parts need that you do not see listed here.

We will do our best to locate the parts you need, and make every effort to save you money.

For parts information in English please CONTACT US

For parts information in English please CONTACT US

Pre-sale Service :

1.You must worry about the products can fit for your parts or not, please don;t worry becaue we double check

with the customers for drawing and machine model, and part no. befor ordering.

2.Excavator&Bulldozer spare parts in full-scale are available;

3.100% quality assurance,develop and manufacture follow original ones;

4. Quick response within 24 hours;

Sale Service:

1. Small order allowed;

2. Reasonable Price and timely delivery;

3. Original packing, neutral packing or customized packing;

4. We will reugularly update customers order producing situation by videos or pictures

5. After finished, we will inspecation all parts in case of any mistakes.

6. We will prepare all documents for custom clerance, such as FORM E, ORINAL, SGS any documents requested.

After-Sales Service:

1.Positive customer feedback from abroad market;

2. Excellent After-sales service.

MITNIK PARTS PACKING

RECOMMEND PRODUCTS

MITNIK COMPANY PROFILE

MITNIK MACHINE PARTS(MMP BRAND)

is the worldwide leader in replacement parts and original parts and accessories for Engineering Machine, Construction Machine, Industrial Truck and Agricultural Equipment over 20 years old.

MITNIK MACHINE PARTS have set up a one-stop shopping platform for engineering construction machinery parts, and the products:involve: excavator&bulldozer undercarriage (track roller, carrier roller, track link, track idler, track link assy, track shoe, segment group, sprocket, bushing, pin, bolt&nut), engaging tools(bucket teeth, bucket tip, bucket, cutting edge, end bit), engine parts (excavator&bulldozer engine parts, engineering truck engine parts etc..), hydraulic parts (hydraulic pump, hydraulic cylinder, quick couple, hydraulic track link pusher machine), dump truck parts, concrete machine parts( easy wearing parts, blades, mixer, shaft, electrical parts).

With more than 20 years experience on heavy duty machinery spare parts sales, our important customers are mainly distributed in South- East Asia, Mid-East, South America and some East European countries.

MITNIK MACHINE PARTS have set up a one-stop shopping platform for engineering construction machinery parts, and the products:involve: excavator&bulldozer undercarriage (track roller, carrier roller, track link, track idler, track link assy, track shoe, segment group, sprocket, bushing, pin, bolt&nut), engaging tools(bucket teeth, bucket tip, bucket, cutting edge, end bit), engine parts (excavator&bulldozer engine parts, engineering truck engine parts etc..), hydraulic parts (hydraulic pump, hydraulic cylinder, quick couple, hydraulic track link pusher machine), dump truck parts, concrete machine parts( easy wearing parts, blades, mixer, shaft, electrical parts).

With more than 20 years experience on heavy duty machinery spare parts sales, our important customers are mainly distributed in South- East Asia, Mid-East, South America and some East European countries.

MITNIK COMPANY ADVANTAGES

SALES AND SERVICE NETWORK

Project in Europe

Project in

Australia

Project in Brazil

FAQ

1. You are a trader or a manufacture?

MITNIK MACHINE PARTS with one-stop shopping platform for engineering construction machinery parts as MITNIK have our own factory and storage warehouse and some parts of them were supply by our Joint Stock Partnership to ensure to provide excellent products and service to our customers, at competitive prices.

We are manufactuer and trade integration business, our factory located on Quanzhou Nanan Distric, and our sales department is in City centre of Xiamen.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or Trade Assurance. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is one 20’ full container and LCL container (less than a container load) can be acceptable.

5. What is your delivery time?

FOB Xiamen or any Chinese port : 20 days . If there are any parts in stock , our delivery time is only 0-7 days.

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

Hot Searches