- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kinggle

-

Year:

-

latest

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6.2*3.8*4.6(m)

-

Hollow part volume:

-

120

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

22.4 kW

-

Extruder Motor Power(kW):

-

55 kW

-

Mold Platen Size(Width)(mm):

-

1200 mm

-

Mold Platen Size(Height)(mm):

-

1200 mm

-

Air Pressure(MPa):

-

1 MPa

-

Air Comsumption(m³/min):

-

1.8 m³/min

-

Die Head Heating Power(kW):

-

35 kW

-

Accumulator Capacity(L):

-

12 L

-

Power (kW):

-

60

-

Weight (T):

-

18

-

Certification:

-

CE ISO

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Name:

-

Plastic Bottle Blow Moulding Machine

-

Product name:

-

Automatic Blowing Molding Machine

-

Key words:

-

Automatic Extrusion Blow Moulding Machine

-

Machine type:

-

High Speed Plastic Bottle Making Machine

-

Type:

-

Semi-automatic Botte-blowing Machines

-

Use:

-

Hollow Moulding

-

Material:

-

HDPE LDPE LLDPE

Quick Details

-

Clamping Force (kN):

-

460

-

Output (kg/h):

-

200 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kinggle

-

Year:

-

latest

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6.2*3.8*4.6(m)

-

Hollow part volume:

-

120

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

22.4 kW

-

Extruder Motor Power(kW):

-

55 kW

-

Mold Platen Size(Width)(mm):

-

1200 mm

-

Mold Platen Size(Height)(mm):

-

1200 mm

-

Air Pressure(MPa):

-

1 MPa

-

Air Comsumption(m³/min):

-

1.8 m³/min

-

Die Head Heating Power(kW):

-

35 kW

-

Accumulator Capacity(L):

-

12 L

-

Power (kW):

-

60

-

Weight (T):

-

18

-

Certification:

-

CE ISO

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Name:

-

Plastic Bottle Blow Moulding Machine

-

Product name:

-

Automatic Blowing Molding Machine

-

Key words:

-

Automatic Extrusion Blow Moulding Machine

-

Machine type:

-

High Speed Plastic Bottle Making Machine

-

Type:

-

Semi-automatic Botte-blowing Machines

-

Use:

-

Hollow Moulding

-

Material:

-

HDPE LDPE LLDPE

Suit product

| Specifications | Unit | Fixed open-closing type | |

| Machiner model | PXB100A | PXB100B | |

| Material | PE,PP,ABS etc. | ||

| Max container capacity | L | 90 | 120 |

| Machine dimension ( L×W×H ) | M | 5.9 ×3.8×4.5 | 6.2 ×3.8×4.6 |

| Machine Weight | T | 16 | 18 |

| Clamping unit | |||

| Mold platen size ( W×H ) | MM | 1080 ×1000 | 1200×1200 |

| Max mold size ( W ×H ) | MM | 800 ×1000 | 920 ×1200 |

| Power | |||

| Servo oil pump motor power | KW | 18.5 | 18.5 |

| Average energy consumption | KW | 43-50 | 52-60 |

| Blow pressure | Mpa | 0.8 | 1 |

| Extruder unit | |||

| Screw diameter | MM | 100 | 100 |

| Screw L/D ratio | L/D | 24:1 | |

| Melting capacit for HDPE | KG/HR | 160-200 | 160-200 |

| Extruder power | KW | 45 | 55 |

| Die head | |||

| Max die-pin diameter | MM | 520 | 520 |

| Accumulator capacity | L | 12 | 12 |

| Accumulator weight ( HDPE ) | KG | 9 | 9 |

Die head: verticality first-in first-out system;

Extruder unit: adopt automatic temperature control unit of import,the screw united by hard tooth surface gear box and frequency motorto achieve stepless speed regulation;

Clamping device: the clamping device of double draw bar is a type of hydraumatic and fixed , draw bar of new type through template,this type is accommodate large size of mould,smooth action,high stability,clamping mould force is uniformly,template is not distortional;

Hydraulic system: whole system adopt imported components,proportional pressure,flow,pressure feedback,system response is faster,action is more smoothly,lowest power loss,and the output of torque is big.

Electric controlling system: it adopts Japan programmable controller,touch screen,the characteristic of it has direct manipulation and large information on board.

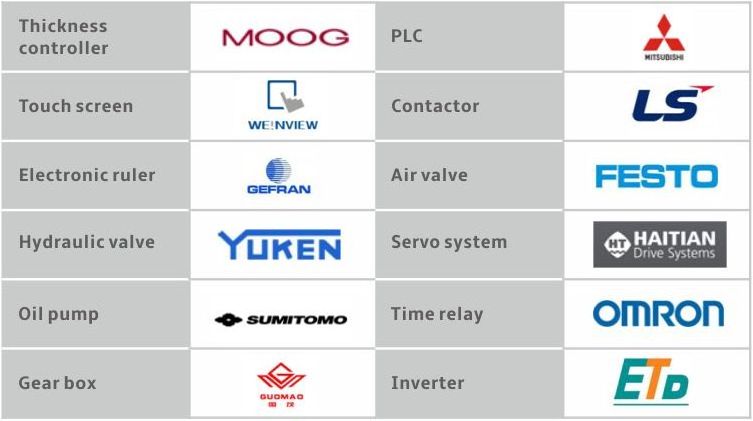

Main component brand

Other Product types

|

|

The warranty period for Kinggle machine is one year with a life long maintenance .

If the user requires special quality guarantee, other stipulated warranty period may be made after

mutual agreement.

|

1. Reply the email and take action in 24 hours . |

|

2. 100% Quality inspection before the shipment. |

|

3. Can trainning clients operator for free in seller`s factory. |

|

4. Engineer overseas is avilable . Introduce our engineer come to customer’s factory working. |

|

5. Blowing mould and injection mould made orginal. |

|

6. Auxiliary machines for complate line . |

|

7.Custimized design as requirements. |

[1] Q: Are you a factory or trading company?

A: We are a factory. Our factory is near Shanghai & Ningbo port, Ningbo ,zhejiang .

[2] Q: Do you provide blow molding machine ,mold and auxiliaries equipments?

A: Yes, we can provide full blow molding machine line. The machine can produce Max 10,000L items, our

factory have patent for the multilayers and multi-colors!

[3] Q: How about quality control in your factory?

A: “ Quality is the key point, do what customers need” . Kinggle machinery factory focuses on quality, quality control from beginning to the end. Every piece of goods is tested strictly before packing and delivery.

[4] Q: How about guarantee ?

A: One year guarantee, oversea service is avaliable.

[5] Q: What is the language of the PLC and touch panel?

A: Don’t worry, we will translate the language in English,or other languages to make sure you will have an easy operation .

The easiest contact way is click the bottom "Send" below