- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1800*730*1700mm

-

Weight:

-

500, 50kg

-

Working Pressure:

-

16 bar

-

Product name:

-

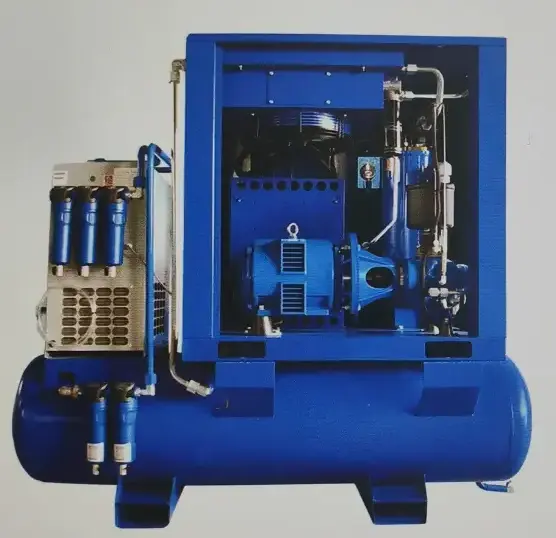

220v 15kw 16kg screw air compressor for fiber laser machine

-

Model:

-

GC-AC

-

Displacement:

-

1.3 m³/min

-

Power:

-

15kw

-

Working pressure:

-

1.6Mpa

-

Noise db(A):

-

60±2

-

Dimension:

-

1800*730*1700mm

-

Applicable laser:

-

3000W

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

GoodCut

-

Voltage:

-

380v/3ph/50hz

-

Dimension(L*W*H):

-

1800*730*1700mm

-

Weight:

-

500, 50kg

-

Working Pressure:

-

16 bar

-

Product name:

-

220v 15kw 16kg screw air compressor for fiber laser machine

-

Model:

-

GC-AC

-

Displacement:

-

1.3 m³/min

-

Power:

-

15kw

-

Working pressure:

-

1.6Mpa

-

Noise db(A):

-

60±2

-

Dimension:

-

1800*730*1700mm

-

Applicable laser:

-

3000W

GoodCut big power 220v 15kw 16kg screw air compressor for fiber laser machine

Compressed air as auxiliary gas:

1). For carbon steel plates, when compressed air is used as the auxiliary gas for cutting, the section of the part will generate relatively small burrs. The burrs are not sharp, and can be applied to parts that do not require high cutting surface.

2). Stainless steel plate, compressed air is used as auxiliary gas. After the material is processed, the cutting surface will be oxidized. When the cutting section is welded, the oxide will produce slag and pores in the weld bead, which will affect the quality of the weld and cause the strength of the welded part to decrease. Therefore, if the compressed air is used as an auxiliary gas for cutting, and the parts need to be welded after cutting, the oxide layer of the welded part needs to be polished to improve the welding quality; in addition, the oxidation of the cutting surface will become a yellow oxide layer, When re-welding, the oxide layer needs to be polished.

3). Aluminum plate and aluminum alloy plate, which uses compressed air as auxiliary gas, will reduce the cutting burr; if using nitrogen, the cutting burr will increase.

GoodCut big power 220v 15kw 16kg screw air compressor for fiber laser machine

|

Laser cutting three auxiliary gases:

1), Laser cutting machine uses different auxiliary gas to cut different materials. The thickness of the cutting material is not used, the pressure of the auxiliary gas and the required flow rate are different.

2), There are three kinds of auxiliary gas for laser cutting machine, laser gas, compressed air, auxiliary gas Laser gas: the gas used to generate laser in the laser generator Compressed air: generally used to protect the optical path, can also be used as auxiliary gas Auxiliary gas: gas ejected from the cutting nozzle of the cutting machine

3), Oxygen for carbon steel cutting is generally required to have a purity of 99.5% or higher. The main function is to support combustion and blow off the cut melt. The pressure and flow rate vary according to the requirements of the cutting machine manufacturer. It is related to the size of the cutting nozzle model and the thickness density of the material. The general pressure requirement is 0.3Mpa-0.8Mpa, the flow rate is not fixed, such as cutting 22mm carbon steel, and some manufacturers require 10m3/h (including the use of oxygen (Protect double-sided cutting nozzle).

4), Nitrogen is used for cutting stainless steel to prevent oxidation reaction and blow off the melt. The purity of nitrogen is particularly high (stainless steel with a thickness of more than 8mm, the purity must reach 99.999%), and the pressure is generally above 1.0Mpa. If you want to cut For stainless steel above 12mm or 25mm thickness, the pressure requirement will be 20Mpa or higher. The flow rate is determined according to the type of cutting nozzle. Generally 12mm thick stainless steel, the flow rate needs 150m3/h, and the thickness is 3mm stainless steel plate, the flow rate is 50m3/ h. |

PLC controller functions of our screw air compresosr:

1. Touch screen display shown

- loading and unloading status

- working hours

- current pressure, temperature

- full-load operation hours

- filters and oil replacement time

- running status

- motor running status

- main motor currency

- electric current

- cooling fan current

- cooling fan operation status

2. Automatically alarm functions:

- high temperature alarm

- oil change-over time arrive alarm

- air filter change-over time arrive alarm

- pressure, temperature sensor fault alarm

- oil filter change-over time arrive alarm

- oil separator change-over time arrive alarm

- communication fault alarm

- belt extended use alarm(belt driven compressor)

- Special design for laser cutting machine

-

16bar high pressure customized for laser cutting industry

-

High pressure,high efficiency cutting

Jinan GoodCut CNC Machinery Co.,Ltd.

GoodCut has Purchasing department, The design department, The production department, Quality inspection department, packaging and transportation department, The sales department, After sales service department.

We can offer highest quality machine, and competitive price.

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 50 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.