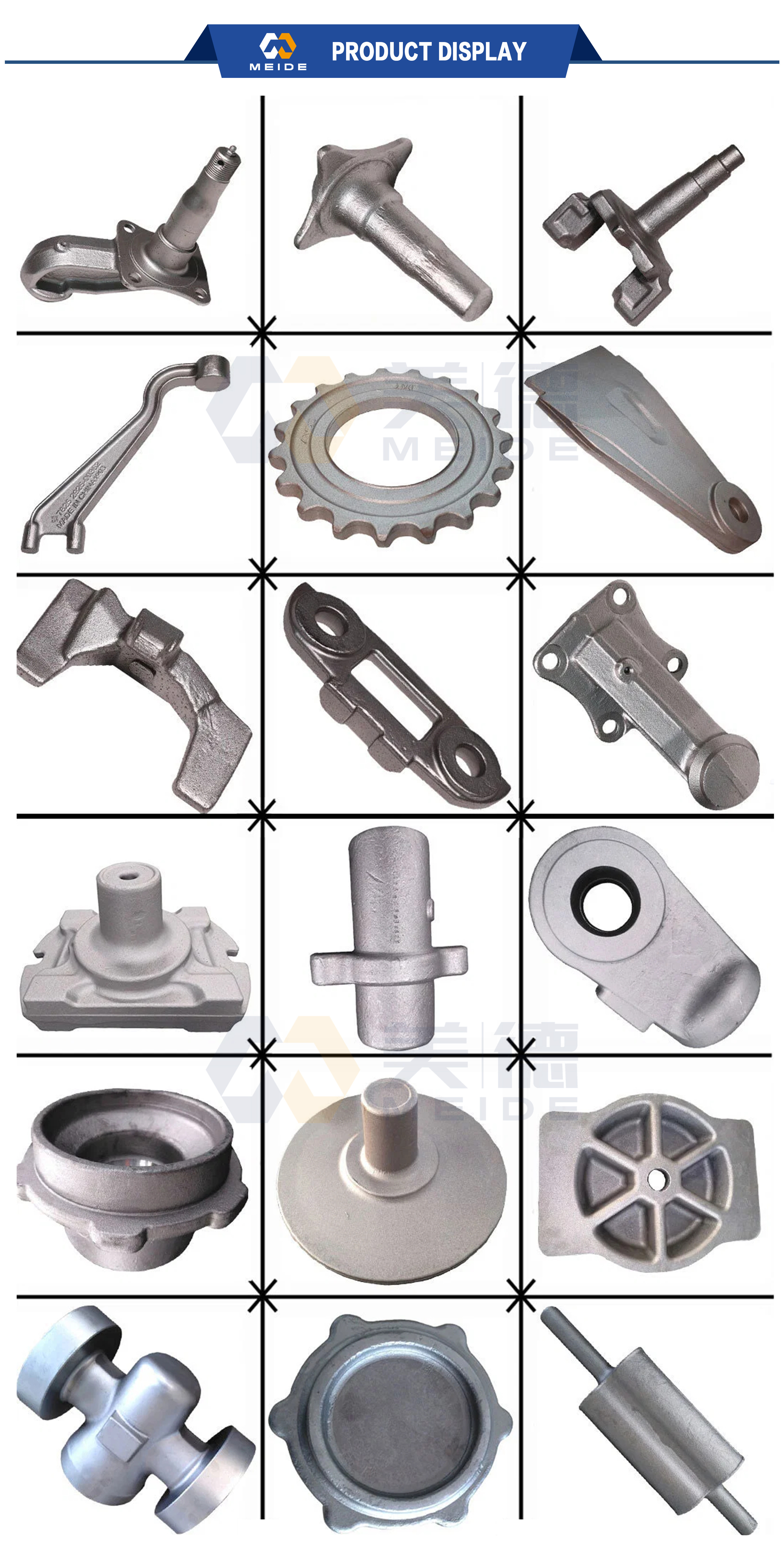

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Copper aluminum steel stainless steel titanium

-

Product name:

-

Forging Metal Parts

-

MOQ:

-

10 Piece

-

Keyword:

-

OEM Hot Forging Parts

-

Application:

-

Industry

-

Surface treatment:

-

Polishing

-

Service:

-

OEM\ODM

-

Process:

-

Forging+Machining(if Need)+surface Treatment

-

Certificate:

-

ISO9001

-

Size:

-

Customer's Requst

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Meide

-

Model Number:

-

customization

-

Material:

-

Copper aluminum steel stainless steel titanium

-

Product name:

-

Forging Metal Parts

-

MOQ:

-

10 Piece

-

Keyword:

-

OEM Hot Forging Parts

-

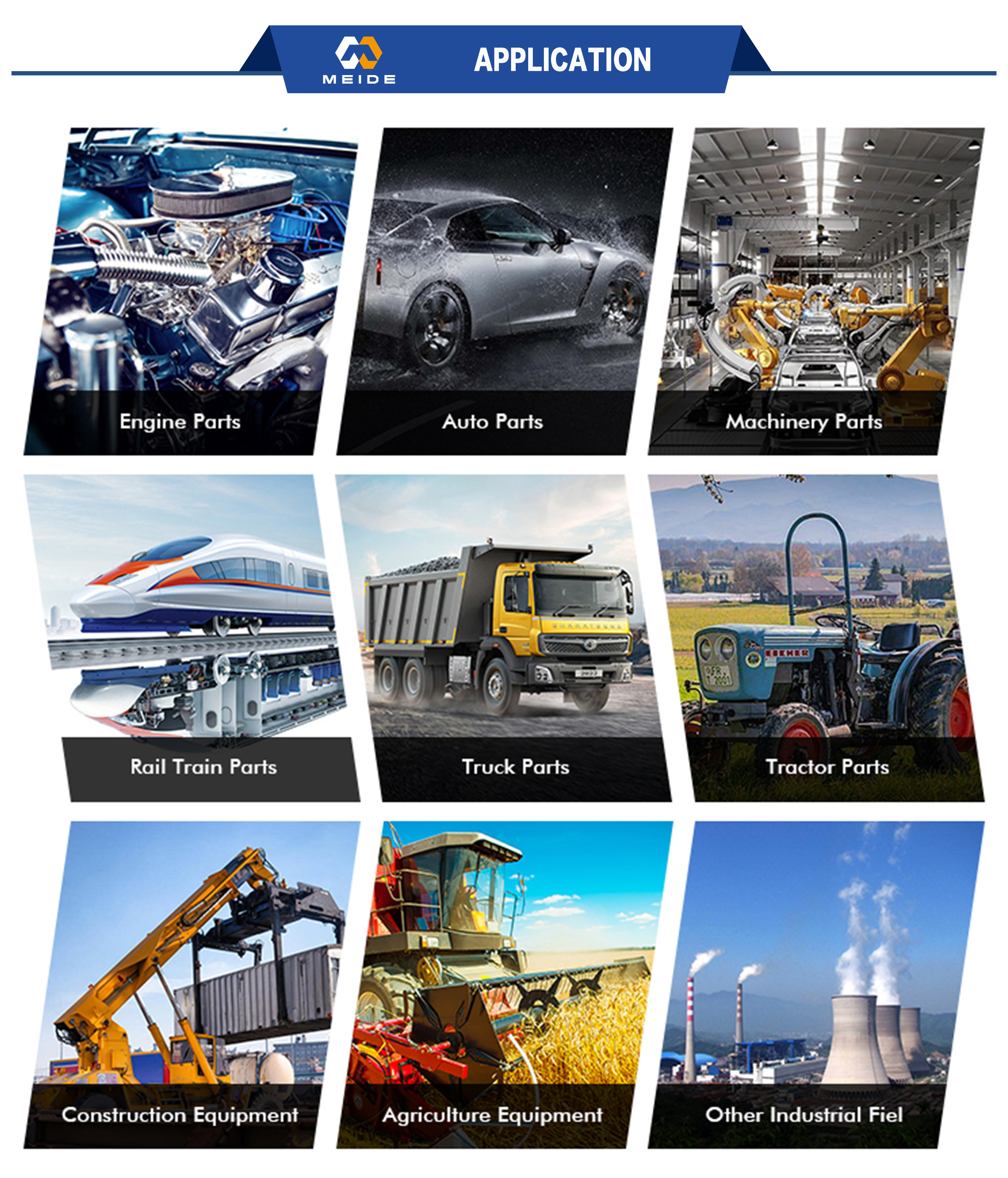

Application:

-

Industry

-

Surface treatment:

-

Polishing

-

Service:

-

OEM\ODM

-

Process:

-

Forging+Machining(if Need)+surface Treatment

-

Certificate:

-

ISO9001

-

Size:

-

Customer's Requst

Product Description

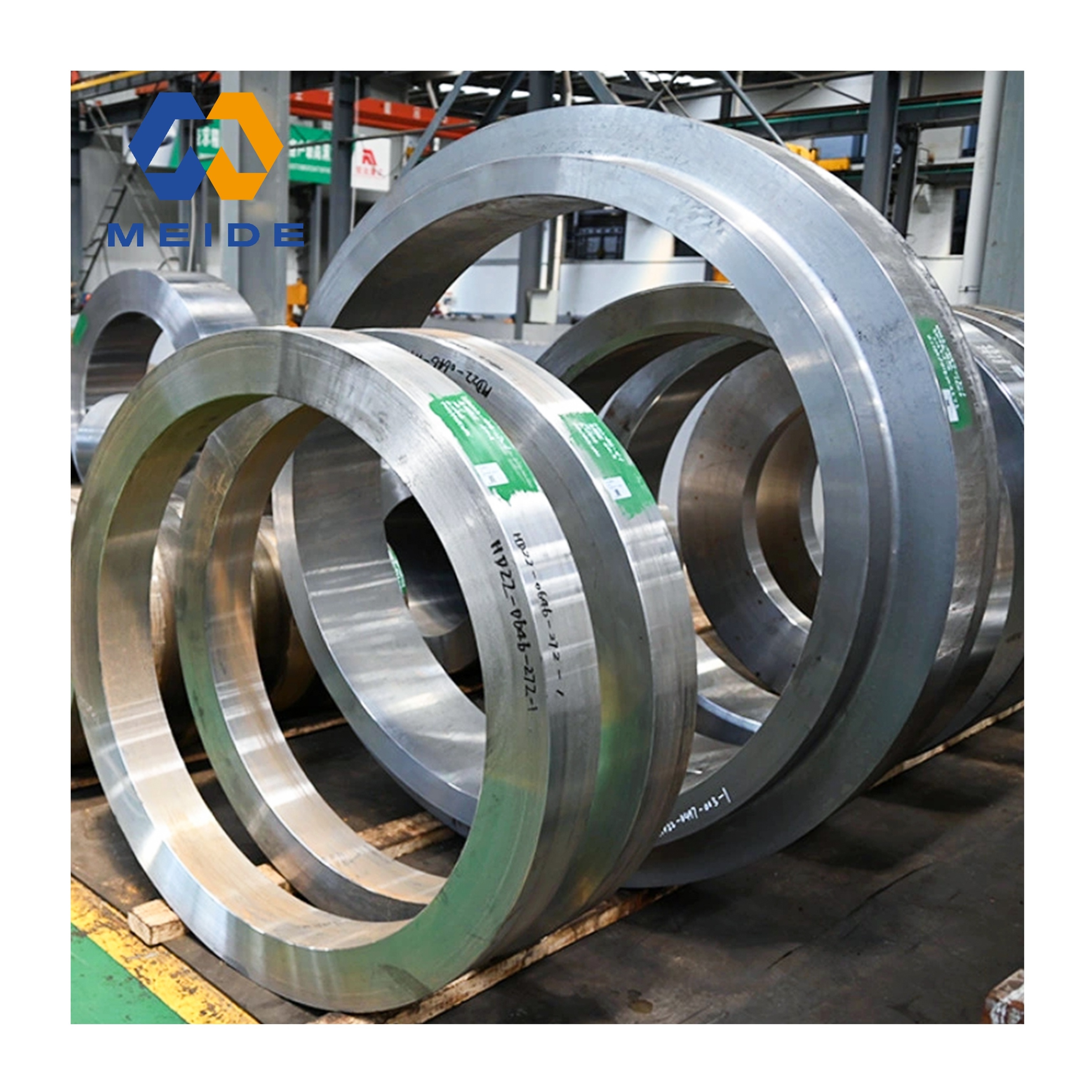

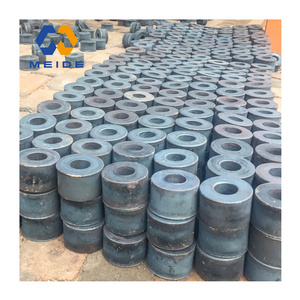

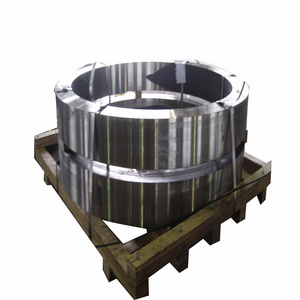

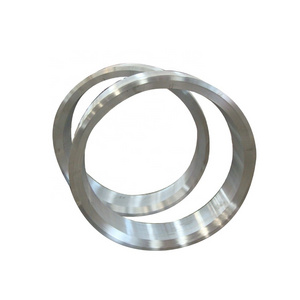

Forgings are workpieces or blanks obtained by forging and deforming metal blanks. According to the temperature of the blank during processing, forging can be divided into cold forging and hot forging. Cold forging is generally processed at room temperature, and hot forging is processed at a higher recrystallization temperature than the metal blank.

|

Available Material:

|

Brass,Copper,Carbon Steel,Stainless Steel,Steel Alloy,Aluminum Alloy,etc.

|

|

Heat Treatment:

|

Annealing,Quenching,Nitriding,Hardening,Tempering,Normalizing,etc.

|

|

Tolerance:

|

As per drawing.(+/-0.05mm,+/-0.01mm)

|

|

Surface Treatment:

|

Zinc-Plated,Nickel-Plated,Chrome-Plated,Anodize,Phosphating,Chemical Blackening,Salt Bath Nitriding,etc.

|

|

Lead Time:

|

20-45Days Depends On Quantities and complexity

|

|

Application:

|

Forklift,Crane,Train,Truck,Lawnmower,Rail Road Euipment,medical device, industrial machine, automobile, electric

appliance,Automation machine,other industries,etc, |

|

Payment Term:

|

L/C at sightT/T 30% deposit and balanced 70% to pay before shipment.

|

|

Port Of Loading:

|

Shanghai or Ningbo,etc.

|

|

Production Equipment:

|

CNC Machining center,CNC Lathe,Grinding Machine,Milling Machine,Sawing Machine,Welding Machine,Hydraulic Press Machine,Drilling

and Tapping Machine,Gear Shaping Machine,etc. |

|

Inspection Equipment:

|

Electronic Penumatic Measuring Instrument,Three Coodinate Detection Equipment,Rockwell Hardness Tester,Digital Ultrasonic Flaw

Detector,Surface Roughness Measuring Instrument,Leeb Hardness Tester,Cladding Measuring Instrument,Salt Spraying Tester,Gear Measurement Center,etc. |

|

QC:

|

1.Incoming material will be checked before production.2.Strict processing quality control.

3.100% inspection before shipment. 4.We are responsible for product quality to the end user. |

|

Package:

|

Method 1:Carton box or corrugated carton

Method 2:Wooden case or wooden crate Method 3: Iron basket or plastic basket Method 4: Pallet |

|

After-sales Service:

|

We will follow up goods for customers and help to solve problems after sales.

|

Technical Support

Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

|

Carbon Steel

|

A350LF2、 A105、Q235、Q355D、A694F52、A516-GR65、EN10222、P280GH、P245GH、P250GH、JIS S25C、SS400、S20C、16Mn、C22.8、Q345B/C/D、1055、1045、C50、C45、10#、20#、35#、45#、40#、50#、60#

|

|

Stainless Steel

|

ASTM、A182、F304/304L、 F316/316L、 F316H、F310、 F321、JB4728-2000、

OCR18Ni10Ti、JB4728-2000、OCR17NI12Mo2、2205、2507、2103、904L、254SMD、304LN、316LN、1CR13、2cr13、3cr13、4cr13、321、302、W1813N、W2014N、W2018N、W2020N、P550、Cr18Mn18N |

|

Alloy Steel

|

42CrMo、A182F1、F5、F9、F11、F91、F92、F22、12Cr2Mo1、10Cr9Mo1VNbN(F91)、10Cr9MoW2VNbBN(F92)、JB4726-2000、15CrMo、JB4726-2000、12CrMoV、35CrMo、4140、4340、4330、4130、4150、9CR2MO、17NiCrMo6-4、18CrNiMo7-6、20MnMo、25CRMO、20CRMO、20CRMOTI、30CrNiMo8、34CRNIMO、34CrNiMo6、36CrNiMo4、34CrNi3Mo、34CrMo1、40CRNIMO、40CrNiMoA、50CrMo4、Q345D、300M、17-4PH、PH13-8Mo、15-5PH、AerMet100

|

|

Aluminum

|

5051,5052,6061,6062,6063,etc

|

|

Brass

|

H58,H59,H62,etc

|

|

Others

|

Titanium Grade 3,Grade 5, Tin-bronze, Plastic, Pom, PP, PE,etc

|

Manufacturing capacity covers the entire production process of forging parts, from mold design and manufacturing, forging, secondary processing, heat treatment, surface treatment to finishing, to provide customers with ready-to-use products and services.

|

|

1) 0-100kg: express & air freight priority

|

|

|

2) >100kg: sea freight priority

|

|

|

3) As per customized specifications

|

|

|

All parts are custom made according to customer's drawings or samples, no stock.

|

FAQ

Q1: Are you a factory?

A: We are a factory set up more than 25 years ,we accept OEM/ODM orders.

Q2:When can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price .Please call us or tell us in your email so that we reply your inquiry with priority.

Q3: How to custom-made (OEM/ODM)?

A:If you have a new product drawing or a sample .Please send to us ,and we can custom -made the hardware as your required .We will also provide our professional adnices of the products to make the design to be more realized &maximize the performance.

Q4: How should I order and make payment?

A: By T/T ,for sample 100 % with the order ,for production ,30% paid for deposit by T/T before production arrangement,the balance to be paid before shippment.

Q5: What is the delivery time ?

A: Delivery will occur between to 10-15 days after date .Faster delivery time can be arranged if needed.

Hot Searches