- Product Details

- {{item.text}}

Quick Details

-

Applicable Models:

-

All

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BEACON

-

Model Number:

-

DPF regenerator

-

Warranty:

-

12 Months

-

Power supply:

-

220V/380V

-

Material:

-

Steel Material

-

Display:

-

LCD Screen

-

Certification:

-

CE

Quick Details

-

Car Fitment:

-

AACHEN SCHNAZER AC SCHNITZER

-

Voltage:

-

220V and 380V

-

Power:

-

50HZ/60HZ

-

Applicable Models:

-

All

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BEACON

-

Model Number:

-

DPF regenerator

-

Warranty:

-

12 Months

-

Power supply:

-

220V/380V

-

Material:

-

Steel Material

-

Display:

-

LCD Screen

-

Certification:

-

CE

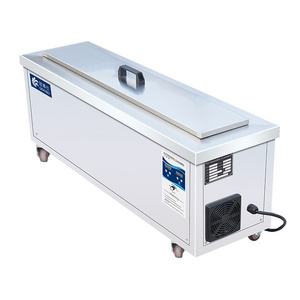

Intelligent DPF SCR high temperature regeneration system cleaning machine

Product Description

Introduction:

The full English name of DPF is "Diesel Particulate Filter", which literally translates to "diesel particulate filter", also called diesel particulate capture regenerator. It is a device that can reduce the emission of particulate matter (PM) in the exhaust. During the working process of the trap, particles will accumulate in the filter. When it reaches a certain value, it will cause the engine's power and economic performance to decline. The deposited particles must be removed in time to ensure that the DPF continues to work normally. It is the so-called DPF regeneration. DPF is also called wall-flow particle trap. Its core function is that after engine exhaust passes through DPF, gaseous pollutants can flow out through the pore wall, and particles are trapped inside the DPF by the pore wall. Then, under certain conditions, the carbon (C) particles are converted into gaseous substances and discharged. The core of the diesel engine exhaust carbon particles (soot) collected in the DPF is solid carbon (C), and the outside contains polymers produced by incomplete engine combustion. In layman's terms, its role is to collect the carbon particles in the exhaust first, and then concentrate them to a certain extent, to convert exhaust pollutants into non-polluting gases.

The realization of DPF's function in the whole vehicle mainly has two parts, namely the capture of carbon particles and the reaction treatment of carbon particles. DPF generally adopts a wall-flow filter, which relies on alternately blocking the inlet and outlet of the carrier holes and forcing the airflow through the porous wall to achieve particle capture. The front-stage DOC catalyst oxidizes the NO produced by the combustion in the diesel engine cylinder to produce NO2. After entering the DPF, the NO2 molecular bond can be broken at a relatively low temperature (about 250°C), and the generated oxygen will combust with the captured C particles to form CO2. Most ordinary driving conditions of diesel engine can meet the regeneration temperature (250℃~500℃) in DPF, so PM can be effectively removed. In the particle trap, electric heating is used to generate high temperature, and the trapped particles are burned into CO2 and discharged.

Due to the wall-flow structure design of the DPF, the dry soot on the DPF and the ash generated after regeneration of organic matter (mainly lubricating oil ash, sulfate, phosphate and other calcium salt and zinc salt ash) during use will be long-term Accumulation will cause the DPF to be blocked, and it will not be able to complete the cleaning and repair by itself, so that the function will be weakened or even invalid. The process of artificially repairing its own function is called DPF artificial regeneration.

DPF high-temperature regeneration equipment is a special equipment for DPF high-temperature regeneration, which integrates beautiful appearance, high efficiency and energy saving, independently developed and produced by our company. A number of new technologies have been applied and have independent intellectual property rights. During the cleaning and regeneration process, the main emissions are CO₂ and CO, which can almost ignore environmental pollution; there is no need for water and other soluble media in the regeneration process, so it will neither waste water resources nor cause chemical pollution to the ecological environment. It will not cause corrosive damage to the carrier itself. At the same time, the high temperature regeneration has no effect on the DPF design performance. The equipment has a wide range of applications and is easy to use and operate, and is suitable for the regeneration of various types of DPF devices.

|

1

|

DPF high temperature regeneration equipment has high heating efficiency, fast speed and good effect. It not only saves electricity

and energy, but is also easy to maintain and low maintenance costs. Under normal circumstances, the time block from the start of heating to the regeneration temperature. High temperature control accuracy and sensitive response |

|

2

|

The use of special scientific insulation layer design and the use of special insulation materials greatly reduce the heat loss

caused by heat conduction, thereby greatly reducing energy consumption; a relatively closed regeneration environment can effectively reduce thermal radiation pollution, and then Protect the ecological environment and the health of operators. |

|

3

|

The multi-stage temperature control function design of preheating section, initial regeneration section and regeneration section

can effectively protect the carrier and fully regenerate. The user can set the regeneration temperature, regeneration power, temperature retention, and temperature retention time according to actual needs. You can also optimize the power consumption according to your own power supply situation. |

|

4

|

The design has a high temperature warning light flashing function, and has multiple safety protections, so that you can use it

with satisfaction, rest assured, and peace of mind! |

|

5

|

Design an air supply device to supply sufficient air required for carrier regeneration. The upper part is designed with a smoke

exhaust pipe, and the smoke pipe part is equipped with smoke elimination parts, which can greatly reduce the pollution to the environment. |

The DPF purge detection dust collection equipment simulates engine exhaust. Before regeneration, the performance of the faulty system or device is tested and displayed and recorded in the form of a curve. After regeneration and purging is completed, the system or device's various ventilation points and Back pressure and other parameters are tested in a curve to compare and analyze the regeneration effect. The pressure difference detection before and after regeneration can be performed on the system or device for comparison and analysis of the regeneration effect.

The system can also choose a weighing method according to user needs, and compare the weight of the carrier before and after regeneration to determine the regeneration effect.

It has the function of light penetration detection for cracks.

The equipment adopts single-chip microcomputer control, high-grade, convenient operation and reliable performance

The air volume-back pressure curve test before and after the assembly regeneration can be performed, and the test results can be recorded in the form of a curve, and then the two curves

can be compared to determine the regeneration effect.

The air volume-back pressure curve test before and after the carrier regeneration can be performed, and the test result can be recorded in the form of a curve, and then the two curves can be compared to determine the regeneration effect.

With pulse blowing function, it is helpful to remove the soot attached to the carrier; with large air volume blowing function, it can blow a large amount of floating dust, and it is equipped with a blowing gun, which can carry out targeted blowing of locally attached smoke and dust .

In the case of pulse blowing, the blowing frequency and blowing intensity can be arbitrarily set according to the needs; when blowing with large air volume, the blowing volume can be set arbitrarily as needed to improve the blowing effect.

Closed purge chamber design, through the vacuum fan, the purged dust is effectively removed, and through a specially designed filter device, the dust and carbon dust are effectively collected, and the mixed gas is filtered clean, which greatly reduces and eliminates environmental damage. Contamination and injury to operators. Fast and convenient, thorough and effective, sanitary and environmentally friendly.

The pipeline adopts all-stainless steel design to avoid the corrosion of the pipeline due to the humid environment, which will cause the secondary damage of the regenerated parts.

The cleaning room is brightly lit and equipped with an observation window, which can effectively observe the blown parts. The simple and easy-to-operate clamp structure can be used to clamp parts conveniently, quickly and reliably.

According to user needs, a database software platform can be established. Users can edit and establish reference ventilation and reference pressure difference (back pressure) parameter databases for each type of DPF device according to the actual situation, for comparison of the effects of failed DPF devices after regeneration.

You can choose to equip the printer function to form a record file of the test results. User-friendly design can be made for printing content according to user needs.

Parameters

|

1. Power:

|

380V AC 220V(Optional)

|

|

2.Phase

|

Three,single(Optional)

|

|

3. Frequency

|

50HZ /60HZ

|

|

4. Rated Capacity(KW)

|

≤13.5 KW

|

|

5.Liquid Temperature(°C)

|

55-70 °C

|

|

6.Working Temperature(°C)

|

0-40 °C

|

|

7.Net Weight(KG)

|

350KG

|

Packaging&Delivery

Our Company

Beacon Machine Manufacturing Co.,ltd located in Taian City Shandong Province P.R. China, is the leading manufacturer specializing

in producing the Diesel Fuel Injection System Test bench in China, also the supplier for Turbocharger Test Bench,Generator Starter

Test Bench,Automobile Gas-way System Test Bench,Automobile Generator Test Bench,Automobile Steering Gear Power Pump Test Bench and

Balancing machine.

in producing the Diesel Fuel Injection System Test bench in China, also the supplier for Turbocharger Test Bench,Generator Starter

Test Bench,Automobile Gas-way System Test Bench,Automobile Generator Test Bench,Automobile Steering Gear Power Pump Test Bench and

Balancing machine.

FAQ

Q1: What is your Trade Terms?

A: FOB CFR CIF EXW DDP and DDU

Q2: What is your payment terms?

A: T/T,Western Union ,PayPay,Escrow and L/C

Q3: What is your delivery time?

A: Test bench is 7-10 working days,tester, diagnostic tool and injectors,we have stock.

Q4: Why should I choose your product?

A: We can provide you the best quality and the most competitive price ,and we have our own engineer,if you have any requirements

you can contact us directly~

A: FOB CFR CIF EXW DDP and DDU

Q2: What is your payment terms?

A: T/T,Western Union ,PayPay,Escrow and L/C

Q3: What is your delivery time?

A: Test bench is 7-10 working days,tester, diagnostic tool and injectors,we have stock.

Q4: Why should I choose your product?

A: We can provide you the best quality and the most competitive price ,and we have our own engineer,if you have any requirements

you can contact us directly~

Contact Us

Hot Searches