Luoyang MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in

bearing zone.

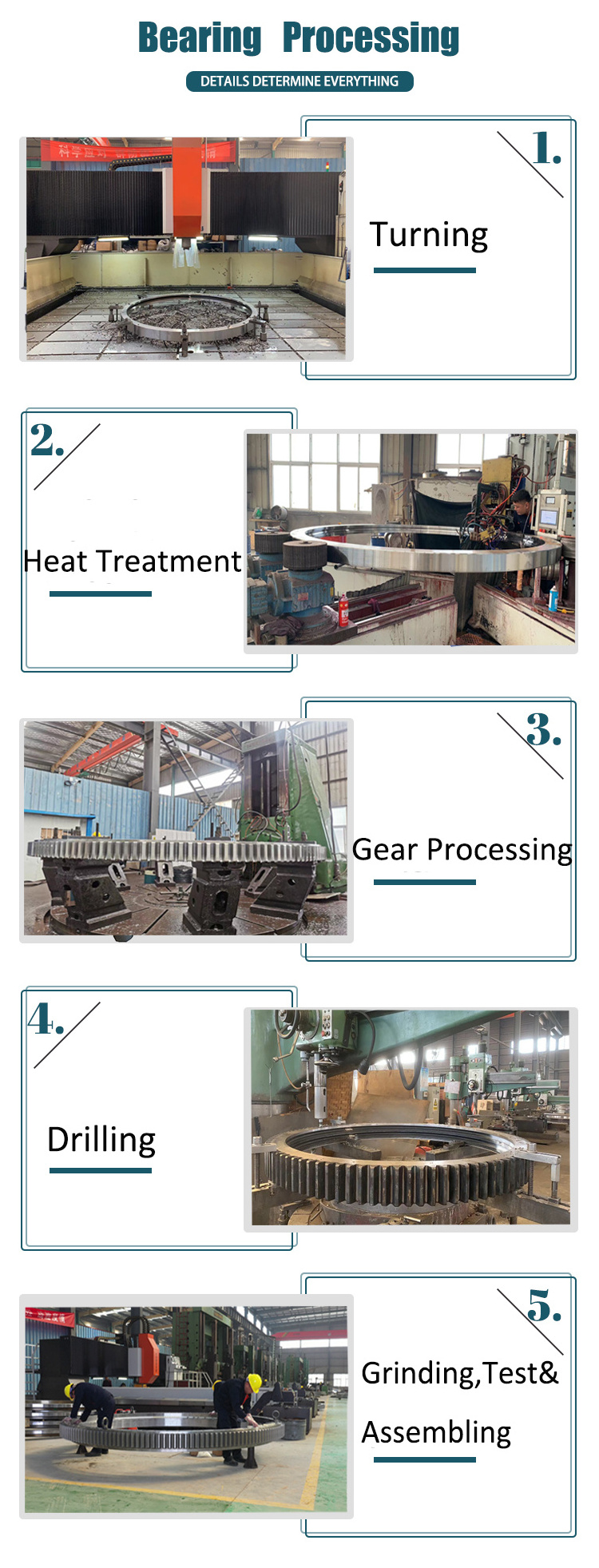

Who focus on Slewing bearing, cross roller bearing,slew drive,gear and pinion,Dia from 50mm-9000mm.

Certificated has

3.1,3.2,ABS,CCS.

Our team with technical and full experience in the bearing industry.

And with a worldwide network, allows us to resolve any bearing issue for you. LYMC bearings are the perfect alternative to the most common and well-known brands.