- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MTALI49

-

Shape:

-

Forging

-

Material:

-

alloy L605

-

Chemical Composition:

-

Co, Cr, Ni, W, Fe, Mn, Si, C, P, S

-

Product name:

-

Cobalt Alloy Forging

-

Density:

-

8.43 g/cm3

-

Melting Point:

-

1300-1410°C

-

1300-1410°C:

-

1035-1725 MPa

-

Yield Strength:

-

690-1450 MPa

-

Elongation:

-

15-30%

-

Hardness:

-

250-360 HB

-

Length:

-

Customizable

Quick Details

-

Application:

-

Aerospace Industry

-

Place of Origin:

-

China

-

Brand Name:

-

MTSCO

-

Model Number:

-

MTALI49

-

Shape:

-

Forging

-

Material:

-

alloy L605

-

Chemical Composition:

-

Co, Cr, Ni, W, Fe, Mn, Si, C, P, S

-

Product name:

-

Cobalt Alloy Forging

-

Density:

-

8.43 g/cm3

-

Melting Point:

-

1300-1410°C

-

1300-1410°C:

-

1035-1725 MPa

-

Yield Strength:

-

690-1450 MPa

-

Elongation:

-

15-30%

-

Hardness:

-

250-360 HB

-

Length:

-

Customizable

MTSCO

Product Description

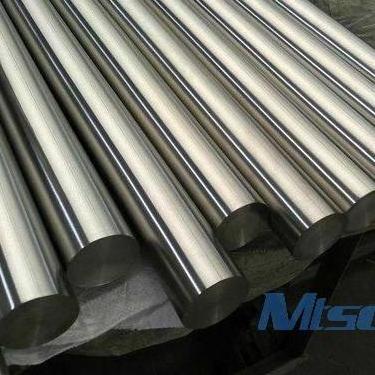

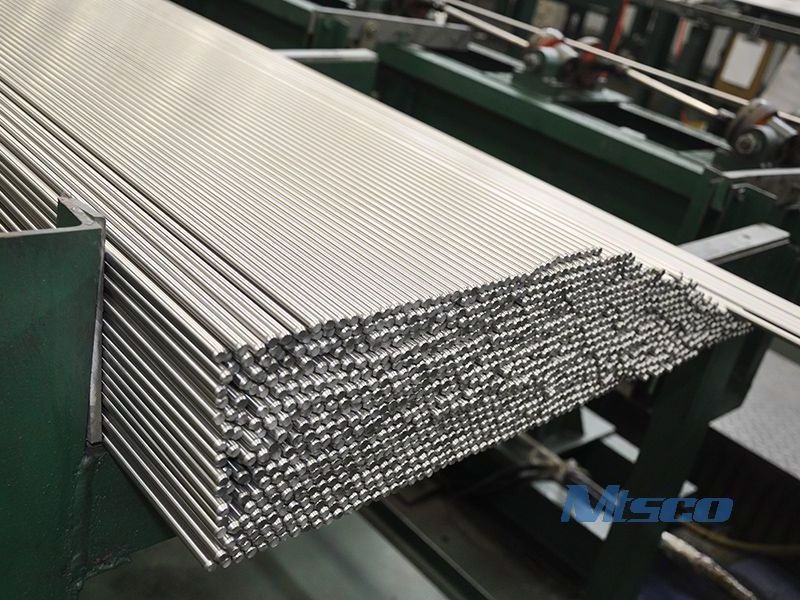

MTSCO high-quality Cobalt Alloy Forging is a perfect fit for the aerospace industry. Made from superior quality cobalt alloy, it has excellent mechanical properties and can withstand extreme temperatures and pressures. This forging is ideal for aerospace applications where high strength, toughness, and corrosion resistance are essential.

|

Material

|

Cobalt Alloy

|

|

Product Type

|

Forging

|

|

Shape

|

Round, Square, or Customized

|

|

Chemical Composition

|

See table below

|

|

Density

|

8.43 g/cm3

|

|

Melting Point

|

1300-1410°C

|

|

Tensile Strength

|

1035-1725 MPa

|

|

Yield Strength

|

690-1450 MPa

|

|

Elongation

|

15-30%

|

|

Hardness

|

250-360 HB

|

Chemical Composition

|

Material

|

Chemical Composition (%)

|

|

Co

|

Balance

|

|

Cr

|

19-21

|

|

Ni

|

45180.00

|

|

W

|

14-16

|

|

Fe

|

3 max

|

|

Mn

|

1 max

|

|

Si

|

0.4 max

|

|

C

|

0.05-0.15

|

|

P

|

0.025 max

|

|

S

|

0.010 max

|

Physical Properties

|

Property

|

Value

|

|

Density

|

8.43 g/cm3

|

|

Melting Point

|

1300-1410°C

|

|

Tensile Strength

|

1035-1725 MPa

|

|

Yield Strength

|

690-1450 MPa

|

|

Elongation

|

15-30%

|

|

Hardness

|

250-360 HB

|

Advantages

Our Cobalt Alloy Forging has superior mechanical properties, excellent resistance to high temperatures and pressures, and exceptional corrosion resistance. It is also highly ductile and has excellent weldability, making it an ideal choice for critical applications where reliability and performance are essential.

Applications

Our Cobalt Alloy Forging is widely used in the aerospace industry for applications such as gas turbine components, aircraft engine

components, and rocket motor cases. It is also used in medical implants and prosthetics, as well as in the chemical and

petrochemical industries.

components, and rocket motor cases. It is also used in medical implants and prosthetics, as well as in the chemical and

petrochemical industries.

Certifications

Hot Searches