- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HR

-

Voltage:

-

220V, 380V

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

1.7*0.65*1.45m

-

Product name:

-

Hot Sale Sawdust Cube Briqutte Making Machine

-

Raw material:

-

Biomass, Sawdust, Corn Cob, Rice husk

-

Finished Products:

-

Wood Briquettes

-

Model:

-

HR50A

-

Color:

-

Customers' Requirement

-

Power:

-

15kw

-

Capacity:

-

260-280kg/h

-

Advantage:

-

Effect Save Electricity

-

Package:

-

Wooden case

-

Application:

-

Make BBQ Charcoal

Quick Details

-

Warranty:

-

3 years

-

Core Components:

-

motor

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HR

-

Voltage:

-

220V, 380V

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

1.7*0.65*1.45m

-

Product name:

-

Hot Sale Sawdust Cube Briqutte Making Machine

-

Raw material:

-

Biomass, Sawdust, Corn Cob, Rice husk

-

Finished Products:

-

Wood Briquettes

-

Model:

-

HR50A

-

Color:

-

Customers' Requirement

-

Power:

-

15kw

-

Capacity:

-

260-280kg/h

-

Advantage:

-

Effect Save Electricity

-

Package:

-

Wooden case

-

Application:

-

Make BBQ Charcoal

Product Overview

Agricultural waste wood sawdust briquette making machine sawdust briquette extruder forming machine

The stick making machine uses sawdust, crop stalks (corn stalks, soybean stalks, sorghum stalks, cotton stalks, rape stalks, peanut seedlings, sunflower stalks), chaff, grasses, shrubs, bamboo and wood stalks, materials, sugarcane Slag and other materials are used as raw materials.

After being crushed by a sawdust crusher, a high temperature and high pressure zone is formed under the action of a screw propeller and a heating ring to process the loose raw materials into a hollow rod.

The product has high density, small size and good combustibility, and can replace firewood and coal.

FEATURES AT A GLANCE

Features of the bar making machine:

1. Rods can be made if the moisture of the raw materials is controlled within 10%.

2. A bar machine comes standard with 1 pusher, 1 forming cylinder and 3 heating rings

3. The propeller has a service life of 3-5 years and needs to be replaced with a new one. There will be wear and tear during use,and it can be repaired.

1. Rods can be made if the moisture of the raw materials is controlled within 10%.

2. A bar machine comes standard with 1 pusher, 1 forming cylinder and 3 heating rings

3. The propeller has a service life of 3-5 years and needs to be replaced with a new one. There will be wear and tear during use,and it can be repaired.

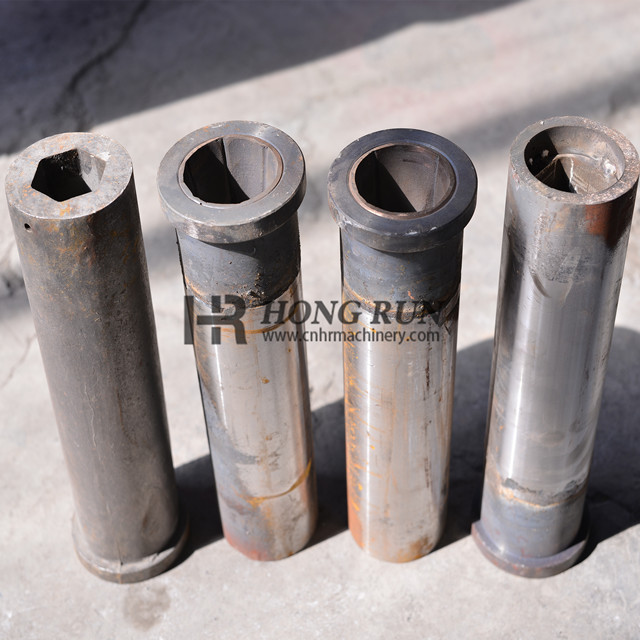

propeller

heating ring

mould

Advantages of the rod making machine from our factory:

Heating ring part: 1. The heating ring has a D-shaped plane with a large heating area.

2. Thick thermal insulation layer, good heat locking effect.

3. Low power, 2 kilowatts, which is more energy-efficient than ordinary 3 kilowatts.

Forming mould part: 4. Adopt double alloy material.

5. Hot pressing technology, thermal expansion without recession, the service life can be as long as 2000 hours.

Propeller part: 6. It is made of 45# steel that has undergone high-temperature simmering and is more durable.

7. Intelligent adjustment of the pitch, increase the output and increase the density of the finished product.

The body part: 8. The body is enlarged, the bearing and the central axis are enlarged, and the service life is increased.

9. The rear axle can be adjusted by 3 cm, reducing the repair of the propeller and extending the use time of the propeller.

10. The silo is enlarged to ensure an increase in the feed volume, and the output of the same configuration model increases by 60kg per hour.

Power distribution cabinet part: 11. Independent power distribution cabinet. We cooperate with Andre Electric, a well-known domestic electrical appliance manufacturer, with quality assurance.

12. Adopt the one-key shutdown device for load-bearing, which can protect the motor or electrical appliances in time.

Motor part: 13. The motor supplier is a well-known brand manufacturer specializing in the production of motors in China. It is also our high-quality supplier. The pure copper movement can work continuously for 24 hours without heating. The warranty is one year. During the period, if there is any quality problem, the new machine will be replaced unconditionally.

Heating ring part: 1. The heating ring has a D-shaped plane with a large heating area.

2. Thick thermal insulation layer, good heat locking effect.

3. Low power, 2 kilowatts, which is more energy-efficient than ordinary 3 kilowatts.

Forming mould part: 4. Adopt double alloy material.

5. Hot pressing technology, thermal expansion without recession, the service life can be as long as 2000 hours.

Propeller part: 6. It is made of 45# steel that has undergone high-temperature simmering and is more durable.

7. Intelligent adjustment of the pitch, increase the output and increase the density of the finished product.

The body part: 8. The body is enlarged, the bearing and the central axis are enlarged, and the service life is increased.

9. The rear axle can be adjusted by 3 cm, reducing the repair of the propeller and extending the use time of the propeller.

10. The silo is enlarged to ensure an increase in the feed volume, and the output of the same configuration model increases by 60kg per hour.

Power distribution cabinet part: 11. Independent power distribution cabinet. We cooperate with Andre Electric, a well-known domestic electrical appliance manufacturer, with quality assurance.

12. Adopt the one-key shutdown device for load-bearing, which can protect the motor or electrical appliances in time.

Motor part: 13. The motor supplier is a well-known brand manufacturer specializing in the production of motors in China. It is also our high-quality supplier. The pure copper movement can work continuously for 24 hours without heating. The warranty is one year. During the period, if there is any quality problem, the new machine will be replaced unconditionally.

|

Name

|

Sawdust Extruder Making Machine

|

|

Model

|

HR50A

|

|

Power

|

15kw

|

|

Capacity

|

260-280kg/h

|

|

Weight

|

800kg

|

spare part

The problems that need to be paid attention to during the debugging process:

1: The rotary speed cannot be too fast

2: Adjust and heat the temperature to 340 degrees first, and after the temperature reaches to 340 degrees, try to put less material first, don’t put too much, afraid of blocking, adjust slowly

3: After finished the rod, slowly lower the temperature to 310, 300, 290, 280, 270. Until the color of the rod is brown, the surface is not black

4: Ensure that the raw material moisture is not higher than 8%

1: The rotary speed cannot be too fast

2: Adjust and heat the temperature to 340 degrees first, and after the temperature reaches to 340 degrees, try to put less material first, don’t put too much, afraid of blocking, adjust slowly

3: After finished the rod, slowly lower the temperature to 310, 300, 290, 280, 270. Until the color of the rod is brown, the surface is not black

4: Ensure that the raw material moisture is not higher than 8%

Product packaging

in wooden case

Shipping in containe

r

Certifications

Company Profile

Hot Searches