For neighborhood countries of China ,such as Mongolia,Kazzkhstan,Uzbekistan etc.we can ship by road or railway.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ORL

-

Product name:

-

steam boiler economizer

-

Brand:

-

ORL

-

Tube material:

-

Carbon steel

-

Keyword:

-

sprial fin tubes

-

Certification:

-

ASME

-

Color:

-

Customized Color

-

Usage:

-

ENERGY SAVING

-

Size:

-

Customzised

-

Feature:

-

Eco-Friendly

Quick Details

-

Type:

-

Fin Tube

-

Application:

-

Heater Parts

-

Weight (KG):

-

5870

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ORL

-

Product name:

-

steam boiler economizer

-

Brand:

-

ORL

-

Tube material:

-

Carbon steel

-

Keyword:

-

sprial fin tubes

-

Certification:

-

ASME

-

Color:

-

Customized Color

-

Usage:

-

ENERGY SAVING

-

Size:

-

Customzised

-

Feature:

-

Eco-Friendly

Product Description

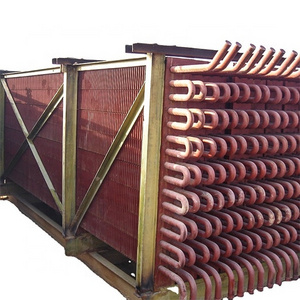

Spiral Fin Tube Boiler Economizer

The SpiralFin Tube Boiler Economizer is an advanced solution designed to optimize energy efficiency and reduce fuel consumption in boiler systems. This economizer features spiral finned tubes that enhance heat transfer, maximizing the overall performance of your boiler operation.

Advantages

Heightened Efficiency:

Our economizer harnesses waste heat to boost the thermal efficiency of your boiler system significantly.

Fuel and Cost Savings:

By reducing the heat generated by the boiler, our economizer lessens fuel consumption, leading to cost savings in the long run.

Increased Surface Area: The spiral fin design increases the surface area for heat transfer, leading to higher efficiency.

Durable and Robust: Made from high-quality materials, our Spiral Fin Tube Economizer offers long-lasting service and exceptional durability.

Environmentally Friendly: By lowering fuel consumption, our economizer reduces CO2 emissions, promoting more sustainable operations.

Increased Surface Area: The spiral fin design increases the surface area for heat transfer, leading to higher efficiency.

Durable and Robust: Made from high-quality materials, our Spiral Fin Tube Economizer offers long-lasting service and exceptional durability.

Environmentally Friendly: By lowering fuel consumption, our economizer reduces CO2 emissions, promoting more sustainable operations.

Usage Precautions:

1. Ensure professional installation to achieve optimal performance.

2. Regular maintenance is essential to maintain high efficiency and prevent potential blockages.

3. The economizer should be operated within its design parameters to avoid damage or system failure.

2. Regular maintenance is essential to maintain high efficiency and prevent potential blockages.

3. The economizer should be operated within its design parameters to avoid damage or system failure.

Economizer types

We can manufacture three types of boiler economizer, bare tube economizer, H-finned tube economizer and spiral finned tube economizer.

1.Bare Tube Economizer

Bare tube economizers are commonly used in large power plants and industrial boilers where the quality of feedwater is high and there's less risk of scaling or deposits.

Typically, these economizers are made from carbon steel, alloy steel, or stainless steel tubes depending on the operating conditions and corrosiveness of the flue gases.

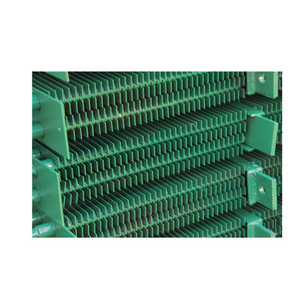

2.H-Finned Tube Economizer

H-finned tube economizer is high efficient heat exchanger economizer which is consisted of H-finned tubes. H-finned tube economizer can enlarge the heat exchange area and reduce the number of tubes. It also can increase the flue gas flow area in order to reduce the flue gas flow speed and abrasion.H-finned tube can be made as double H finned tubes , with high rigidness to fit long tube row.

3.Spiral Finned Tube Economizer

The spiral finned tube economizer is a newly designed heat transfer equipment, consists of spiral fin tubes to overcome the serious abrasion and short service time.

Product Paramenters

|

Tube Material

|

Carbon steel (such as ASTM A179 or ASTM A192), stainless steel (e.g., ASTM A213), or alloy steel (e.g., ASTM A335)

|

|

Fin Material

|

Aluminum and copper

|

|

Header and Manifold Material

|

Carbon steel or Stainless steel

|

|

Material standard

|

ASTM, ASME,EN or GB etc.

|

|

Dimension

|

Customization

|

|

Applications

|

Power plants, Industrial manufacturers, Commercial buildings, Maritime industry, and Waste-to-energy plants

|

|

Process

|

Tube Preparation --> Fins Manufacturing --> Fin Attachment --> Quality Control and Inspection

|

Investing in our Spiral Fin Tube Boiler Economizer delivers a triple advantage: remarkable improvement in boiler efficiency, substantial savings on fuel costs, and a meaningful step towards environmentally sustainable operations. Don't hesitate, reach out to us today to elevate your boiler system's efficiency and your business's sustainability.

Related Products

Boiler superheater

Boiler header

Boiler waterwall panel

Why Choose Us

SUZHOU ORL POWER ENGINEERING CO.,LTD

ORL is a leading compamy of manufacturing industrial boilers, power plant boilers and boiler parts(including steam drum,waterwall panel,heater,economizer,evaporator,superheater,H-finned economizer,spirial fin tube,air preheaters,heat exchangers,flues etc.),We supply clients with seamless steel tubes/pipes(ASME,EN or BS).

Service

ORL provides our customer with full range of services including boiler design,fabrication,installation and commissioning, boiler maintenance,and supervision at site.Our pruduct and service include design and manufacture industrial boilers,pressure vessels and tanks,and pressure parts for power plant boilers(600MW,or 1000 MW).

Certificates

Verification Certificates of equipments:ISO 9001:2015;ISO4001:2015;ISO45001:2018;CE certificate;CNAS;IAF, etc.

Logistics

For 90% of shipment,we will go by sea,to all main continents such as Middle East,Africa,Oceania and Europe etc.Either by container or RORO/Bulk shipment.

Customers

We are a professional manufacturer of industrial boilers in China.With the scientific progressive conception of rapid introduction,we make our machinery cover all over the overseas market.We have been producing our goods with mature techniques and first-class quality.

FAQ

Q1:How long is the warranty period?

We provide 12 months warranty for all spare parts(exclude fragile parts).

Q2:How do you control the quality?

1) All ORL machines are in strict accordance with the ISO quality and CE system requirements.

2) Each procedure is crafted by professional Skilled labour, followed by particular QC

3) All information of our products can be checked in efficient management system.

Q3:What certifications do you have?

All our products are CE and ISO9001 certified. Numerous design and innovation patent for all our current models and spare parts. Such as the innovation patent squeegee design.

Q4:What kind of service do you provide?

Before sales:

Provide product informations, market research forecasting, product customization,product processing,consultation and other services for your convenience.

After sales:

1. Technical training on according to customer requirements;

2. We promise replacement under warranty;

3. We promise to supply the maintenance spare parts;

4. Regular call back or visit customers;

5. On time response to mail and phone calls of your complaints or consultation.

Q5:Are you a factory or trading company, where are you located?

We are a factory, just 100km(2 hours by car) away from Shanghai Airport.

We offer pickup service at Shanghai for your visit.

mail:info@orlpower.com

Tel : +86 (0) 512 5677 0166

Whatsapp:+86 15722601001

Web : www.orlpower.com

Hot Searches