Corrosion level classification:

Through many different ways, different degrees of protection can be achieved. Four types of corrosion protection are listed now

Level 1 (ISO Class 1)

Indoor fixation, with slight corrosion impact. Most galvanized nails/yellow zinc used for interior partitions belong to this grade. The thickness of the electroplating layer is 2-5 microns.

Level 2 (ISO Class 2)

Indoor fixation with certain corrosion requirements. Electrogalvanized/yellow zinc nails usually meet this level. The thickness of the electroplating layer is 10-12 microns.

Level 3 (ISO Class 3)

Indoor fixation, used for moderate industrial pollution and mild marine environments. This category is suitable for general roof and wall applications.

The 1000H anti-corrosion coating nail can meet and exceed this standard through salt spray testing by Pietro Kishbone and Japan's Laspex.

Level 4 (ISO Class 4)

Indoor fixation, used in mild and severe marine environments, classified according to ISO 9223 standard, generally between 100 meters to about 300 meters inland from the coastline. In windy environments, it can extend inland for a certain distance. Fasteners that meet the requirements of Class 4 anti-corrosion coating are used in conjunction with international standard steel (when used in coastal environments between 200 and 400 meters). Whether the selection of fasteners conforms to the usage environment should be tested and evaluated through real natural environment testing When conducting testing at an approved outdoor testing site, 95% of the surface of the fasteners to be inspected must not be covered with red rust. This type of outdoor testing site must be located no more than 500 meters from the coastline, in coastal areas with waves in most seasons of the year.

Pitt Kishbone and Japan's Lasspart salt spray test 1500H anti-corrosion coating nails can meet customer anti-corrosion requirements.

Explanation:

Fix polycarbonate, stainless steel, and aluminum housing in high-strength corrosive environments

When facing the panel, it is recommended to use stainless steel anti-corrosion coating fasteners.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Brusen

-

Model Number:

-

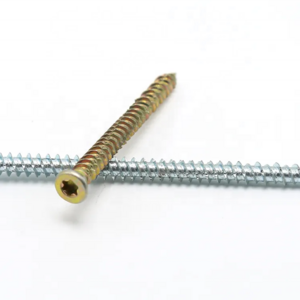

Concrete screw-5

-

Product name:

-

Concrete Screw

-

Size:

-

Customized Size

-

Surface treatment:

-

Customer's Requirement

-

Color:

-

Customized Colors

-

Keyword:

-

Concrete Screw

-

Packing:

-

Cartons+plastic Bags

-

Length:

-

72-152mm

-

Application:

-

Industry

-

Head type:

-

Flat

-

Sample:

-

Availabe

Quick Details

-

Finish:

-

Black, ZINC

-

Material:

-

Steel

-

Measurement system:

-

INCH

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Brusen

-

Model Number:

-

Concrete screw-5

-

Product name:

-

Concrete Screw

-

Size:

-

Customized Size

-

Surface treatment:

-

Customer's Requirement

-

Color:

-

Customized Colors

-

Keyword:

-

Concrete Screw

-

Packing:

-

Cartons+plastic Bags

-

Length:

-

72-152mm

-

Application:

-

Industry

-

Head type:

-

Flat

-

Sample:

-

Availabe

Product Discripton

|

Concrete Screw

|

|

|

|

Screw Diameter

|

7.5mm

|

|

|

Lenght

|

72-152mm

|

|

|

Material

|

C1022A

|

|

|

Support customization, please contact us (

Contact: Andy wsp: +8618812685925

)

|

|

|

From the quality control of incoming raw materials, process control of production lines, and finished product screening control, we ensure that 99% of products meet technical requirements.

Imported material Kishbone anti-corrosion coating surface treatment, acid and alkali resistant, less prone to rust, and more durable.

Smooth surface

The overall surface is smooth without burrs, and the surface is bright and clean as new, with high-quality

workmanship.

workmanship.

The thread is sturdy and not easily deformed

The thread is clear and complete, which can effectively bite and prevent slipping, and is tightened and durable

.

Exquisite craftsmanship and high-quality material manufacturing

Select high-quality carbon steel with galvanized surface (color optional) treatment to ensure quality.

(Imported material Kishbone anti-corrosion coating surface treatment)

Kishbone Imported coatings from Japan

Kishbone low-temperature type is a surface treatment developed for rust prevention of steel products that are prone to changes in properties due to processing temperature.

Kishbone developed a chromium free and highly corrosive surface treatment technology for steel products that are prone to delayed damage caused by hydrogen embrittlement. It consists of two parts: a primer rich in zinc powder and aluminum powder, and a topcoat mainly composed of aluminum powder and organic resin. Qishibang low-temperature type is suitable for steel products where physical properties are prone to changes and processing temperatures are relatively low.

Technical feature

|

Hydrogen free brittleness treatment process

|

|

Due to the absence of electroplating pickling and electrolysis processes for steel, there is no need to worry about hydrogen embrittlement issues. Especially suitable for high carbon steel with high strength differentiation (chromium molybdenum steel and high tension steel)

|

|

|

|

|

|

Environmental ROHS Directive

|

High corrosion resistance

|

|

Not using hexavalent chromium, trivalent chromium, and six substances included in ROHS directives such as lead, radiation, and mercury Quality. Simultaneously comply with REACH instructions.

|

Transform the passivation treatment of the original Laspex into a chromium free special coating. The zinc coating is tightly combined with the topcoat to maintain the same performance as the passivation treatment.

|

|

|

|

|

|

|

|

Low temperature treatment

|

Adjustable friction coefficient

|

Reduce electrical corrosion

|

|

The processing temperature below 200 ℃ will not affect

the physical properties of the product.

|

There are also low friction treatments that can reduce

the friction coefficient, including three types: low, standard, and highfriction.

|

Significantly reduces electrical corrosion when in contact with aluminum and highly corrosive electroplated aluminum (reduces electrical corrosion when in contact with dissimilar metals)

|

|

|

|

|

|

|

|

|

Why is corrosion an issue that cannot be ignored?

For a long time, fasteners have been the weak link in all structural connections of buildings.

It is not a problem with the design or performance of fasteners, but rather a weakening of strength due to corrosion over time, resulting in the loss of fastening effect.

Generally speaking, corrosion is always associated with non rare metals such as steel, zinc, and aluminum. This type of metal is extracted from minerals and rapidly corrodes when air, water, or salt coexist. Under aerobic conditions, hydrides are formed, making the metal surface dull and ultimately leading to safety hazards or waste. Corrosion is a natural process that converts metals into minerals (initial state).

Fastener corrosion can be caused by salt mist from the ocean, gaseous acids from industry and chemistry, ultraviolet radiation from the sun, and moisture from tropical and humid regions. Corrosion greatly affects the performance of fasteners during their lifespan, which in turn affects the long-term structural integrity of buildings. Exposure to corrosive environments may lead to weakened performance, formation of cracks at the bearing area of fasteners, and ultimately failure.

The protective coating on the surface of fasteners follows the principle of "galvanic corrosion". This phenomenon occurs when two different metals come into contact in a corrosive environment. At this point, the more active metal corrodes before the less active metal. If the steel surface is galvanized, the steel is protected until the galvanized layer is completely corroded.

Through many different ways, different degrees of protection can be achieved.

Screw display

Notice:

1.

As a manufacturer, we supply credible products with high quality in timely delivery.

2. All of our products are inspected by QC before packing and checked again before shipping.

3. Non-standards are available, according to your drawing or samples.

2. All of our products are inspected by QC before packing and checked again before shipping.

3. Non-standards are available, according to your drawing or samples.

4.

Standard export package or according to your requirements.

We have the capacity of providing first-class products according to customized product of the clients with favorable price!

Packing

Different package can be customized

1.

Plastic jar packing:

Be favored by supermarkets and brand customers. High quality anti - theft plastic bottle. The number of

screws per bottle can be adjusted according to customer requirements. With the customer's logo and any information that needs to be displayed can be put on the bottle in the form of stickers.

2. Plastic drum packing:

screws per bottle can be adjusted according to customer requirements. With the customer's logo and any information that needs to be displayed can be put on the bottle in the form of stickers.

2. Plastic drum packing:

Essential packaging for brand customers. The extra large capacity can accommodate more quantities or

extra long specifications.

3. Plastic blister packing:

extra long specifications.

3. Plastic blister packing:

Lightweight packaging can perfectly hang on the shelves of supermarket customers.

4. Plastic bag packing:

4. Plastic bag packing:

Simple and portable packaging, There is a seal on the plastic bag to ensure the tightness of the bag.

5. Plastic box mixed packing:

5. Plastic box mixed packing:

Mixed packaging can fully meet the needs of customers. Different box types can be designed. When

customers need different specifications screws at the same time. This will be the best choice.

6. Paper carton packing:

customers need different specifications screws at the same time. This will be the best choice.

6. Paper carton packing:

5-layer corrugated high-quality carton can fully ensure firmness. Different colors and designs can be

customized.

customized.

Factory Display

Complete set of laboratory testing equipment

High precision instruments, layer by layer for quality control

Hardness tester

Torque meter

Tensile Tester

Image measuring instrument

Salt mist tester

Optical screening machine

Test report

Doing every screw well is always our persistent goal

We mainly produced common nail, jolt head nail, duplex head nail, concrete nail, drywall screw, self tapping screw, self drilling screw,U fence staples, cut masonry nail, roofing nail, clout nail and all kinds of nails and screws, we also offer black annealed wire, twisted wire, galvanized wire and wire mesh products used in construction and decoration to meet different customer's requirements.

(Contct: Andy) ( Whatsapp: +8618812685925)

Shopping instructions:

1. Price issue:

Due to daily fluctuations in steel prices, the prices sold are based on our company's actual quotation. The products are all at the factory price, excluding taxes and shipping fees.

2.

Product issues:

We conduct strict quality inspection on all products before shipment to ensure that there are no issues before shipment.

3. Product images:

All products are actual photos, but there may be slight color differences due to lighting and display factors. Please understand.

4.

Product Properties:

B

efore placing an order for purchase, please contact

Andy

(WhatsApp:+8618812685925)

to explain the product model, specifications, dimensions, etc., in order to confirm that the product you need is available.

5. Customized quotation:

The customer provides drawings or samples. The drawings require the following information to be clear: processing quantity, material, precision tolerance, surface treatment, and special requirements.

6. Regarding delivery time:

production time, follow up throughout the process, and communicate and negotiate with the customer 2 days in advance if there are any changes to the delivery time.

Hot Searches