- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 50Hz 3phases or as required

-

Dimension(L*W*H):

-

7.5*1.8*1.7M

-

Weight:

-

7000 kg

-

Warranty:

-

12-18 month

-

Feeding width:

-

Other

-

Marketing Type:

-

hot product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Motor:

-

5.5+4Kw, China famous brand

-

Cutter material:

-

Cr12, quenched

-

Speed:

-

12-15m/min

-

Certification:

-

ISO CE

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

12-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

JCX

-

Voltage:

-

380V 50Hz 3phases or as required

-

Dimension(L*W*H):

-

7.5*1.8*1.7M

-

Weight:

-

7000 kg

-

Warranty:

-

12-18 month

-

Feeding width:

-

Other

-

Marketing Type:

-

hot product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Motor:

-

5.5+4Kw, China famous brand

-

Cutter material:

-

Cr12, quenched

-

Speed:

-

12-15m/min

-

Certification:

-

ISO CE

Product Overview

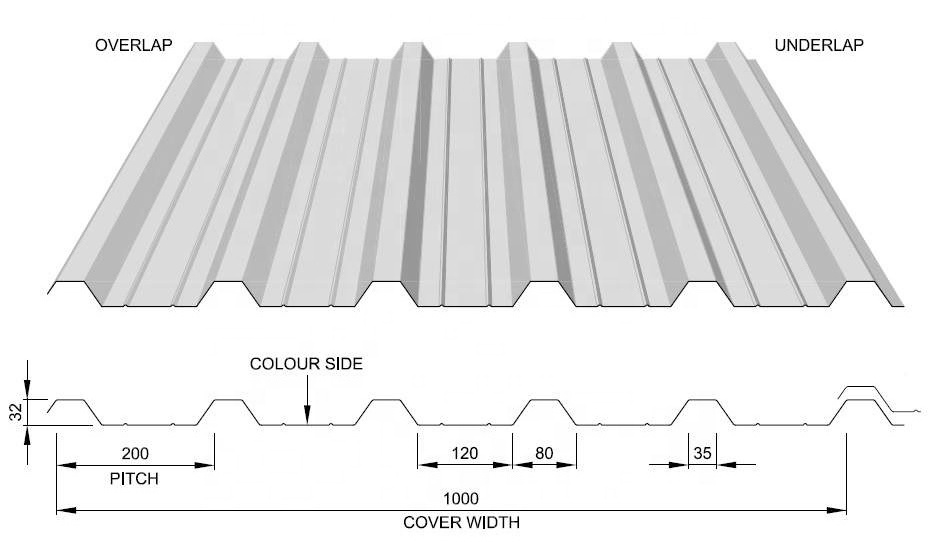

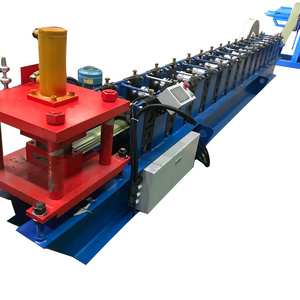

Export to Australia metal fence steel corrugated fence panel roll forming machine

Product Paramenters

|

No

|

Item

|

Parameter

|

|

1

|

Decoiler

|

5tons electric decoiler (Hydraulic decoiler optional), manual one

|

|

2

|

Forming speed

|

12-18m/min

|

|

3

|

Material

|

G235grade steel or galvanized coil

|

|

4

|

Thickness

|

0.2-0.8mm

|

|

5

|

Forming steps

|

15-18 forming steps

|

|

6

|

Shaft

|

Diameter 70/75mmmm, all solid

|

|

7

|

Rollers

|

High grade 45# steel with heat treatment and hard chrome coating 0.04-0.05

|

|

8

|

Main frame system

|

H350 steel. By blasting

|

|

9

|

Motor brand

|

shanghai lichao motor

|

|

10

|

Main forming power

|

4kw.

|

|

11

|

Pump Station Power

|

3Kw

|

|

12

|

Cutting Type

|

hydraulic cutting

|

|

13

|

Cutting Blade

|

Cr12Mov with hard treatment, HRC52-68

|

|

14

|

Control System

|

Delta PLC, Touch screen, Frequency converter

|

|

15

|

Measuring accuracy

|

Precision +/-1.5mm,with frequency converter

|

|

16

|

Transmission

|

By single chain 1’

|

|

17

|

Machine Dimensions

|

About 8.5*1.5*1.7m

|

|

18

|

Machine weight

|

About 5,000 kgs

|

|

19

|

Voltage

|

380V,50hz, 3phase, as per request

|

Components of whole line:

|

Decoiler / Uncoiler

|

1 Unit

|

|

Feeding Guide

|

1 Unit

|

|

Main Corrugated Roll Forming Machine

|

1 Unit

|

|

Hydraulic Cutting

|

1 Unit

|

|

Hydraulic Station

|

1 Unit

|

|

PLC Computer Control system

|

1 Unit

|

|

Runout Table

|

2 Units

|

Details Images

Decoiler

1. Capacity: 5tonsspan.2. Material coil inner diameter: 450mm-550mm

3. Max width: 1250mm

Guiding device

1. Advanced guiding device, ensure the steel roll in correct direction.2. Two layers all equip with pre cutting, save steel roll,

no waste

Main forming machine

Refer to main parameters

Hydraulic cutting

1. Hydraulic cutting system--Guide pillar type or Electric cutting. Speed more faster

Control system

1). Screen:Delta

2). PLC: Delta

3). Automatic length measurement

4). Automatic quantity measurement

Hydraulic station

1).Adopt advanced hydraulic system , with cooling fan.

2).Motor:4kw

3).Hydraulic oil: 40#

Application

Other models of sheet we can do:

Product packaging

Hot Searches