- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

25*10*20M

-

Weight:

-

8000 kg

-

Warranty:

-

12 Months

-

Application:

-

poultry animal feed mill

-

Function:

-

feed pellet making line

-

Capacity:

-

1.5-2T/H

-

Feed pellet dia.:

-

3-8mm

-

Motor:

-

china brand/Siemens

-

The mainly machine is made of:

-

carbon steel

-

Installation:

-

engineers to buyer's feed mill to guide

-

Color:

-

white and green

-

Raw material:

-

corn/maize/soybean /additive

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Double Crane

-

Voltage:

-

220-480 V

-

Dimension(L*W*H):

-

25*10*20M

-

Weight:

-

8000 kg

-

Warranty:

-

12 Months

-

Application:

-

poultry animal feed mill

-

Function:

-

feed pellet making line

-

Capacity:

-

1.5-2T/H

-

Feed pellet dia.:

-

3-8mm

-

Motor:

-

china brand/Siemens

-

The mainly machine is made of:

-

carbon steel

-

Installation:

-

engineers to buyer's feed mill to guide

-

Color:

-

white and green

-

Raw material:

-

corn/maize/soybean /additive

-

Certification:

-

CE ISO

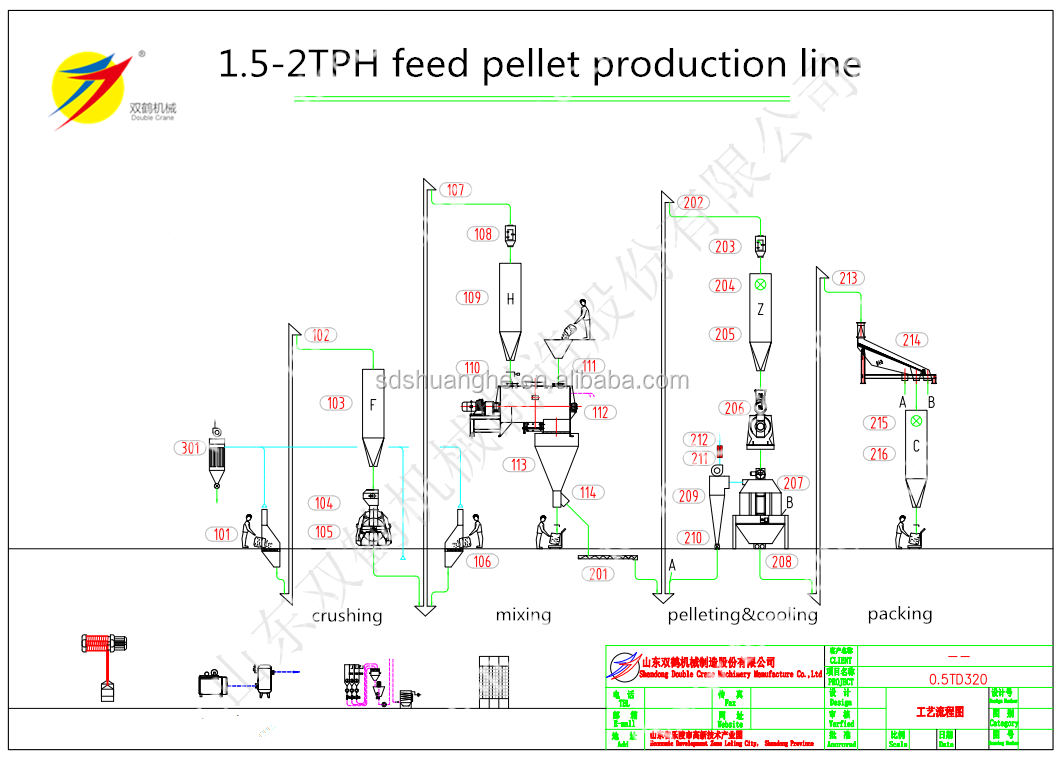

cattle feed mill price in india machinery for making cattle cow feed with 2TPH output

www.feedpelletmachinery.com

If you are looking for the chicken feed pellet line 2 T, you can stop to see this professional design with

manual dosing system with compact structure and simple opearation to reduce the feed mill cost. Our 2 tons

feed pellet making line was been exported to Senegal,Oman,Tajikistan,Greece,Bangladesh and so on.

This feed pellet line mainly contains feed hammer mill, feed mixing machine,feed pellet making machine,feed

cooling machine and packing machine to produce the feed pellet from 3-8 mm diameter for different animal.

Our engineers and installation technology team are backbone to help you in installation and commission with

abundant practical experience. Here are the pictures of the actual feed pellet processing equipment.

1.5-2 T/H poultry feed line with manual ingredients-batching :

The steps: manual ingredients-batching poultry feed pellet production line demand that you weigh all the raw

material feedstock before production.

1.Weigh up solid raw materials such as corn and soybean,wheat and additive in proportion and percentage for

crushing and mixing.

2.put a batch of solid raw material into feed hammer mill for crushing by dust removal and pre-cleaning and

iron removal to avoid machines damage.

3.After crushing, a bucket elevator can transport the crushed particles by bin into feed mixer, at the same, the

additive are lifted into feed mixer by bucket elevator. In the mixing section, all the particle and powder are mixed

homogeneously, you also can add the liquid, oil and molasses to improve the feed taste.

4.The next step is to pelletize after mixing, but if you need some feed mash, a pneumatic Tee can shunt the feed

mash into packing machine as show 207 in flow chart. Others are shunted by bin into feed pellet making machine.

For pelletizing section, it needs to add a boiler to supply the steam for conditioning to improve feed quality and

feed pellet shaping and sterilize.

5.The feed pellet produced are about 60-80 degrees centigrade , the cooling machine is necessary to cool down 3-5

degrees centigrade with counterflow cooling principle to avoid feed pellet surface crack with good cooling effect.

The cooling time is controlled by double level indicators: high and low level indicator, when the feed pellet is up

to high level indicator to discharge, if the feed is reach to low level indicator to stop discharging.

6.The vibrating screen are used to sieve the similar feed pellet for next packing.

7.Automatic packing scale can realize bag clipping,packing ration and bag seaming and feed pellet package

conveying.

Main Features

2.The complete poultry feed line has no redundant machine,only select the machines which are necessary

for make the whole poultry feed pellet line normal running.

3.Each the machine capacity of poultry feed making line hourly is correlative to guarantee the whole line output.

4.Scientific machines arrangements can warranty the yield to save energy and raw material consumption and cost

5.With a high degree of automation,mechanization and flexibility.

Hammer mill

1.capacity:3-4.5 T/H

2.rotor diameter: 560mm,crushing chamber

width: 400mm

3.hammers:tungsten carbide180*50*5,QTY:48Pcs

4.Driven by motor,china brand

5.Rotor balance is tested with reverse operation, door is

equipped with safety interlock device , hammers are

arranged symmetry.

Single ribbon feed mixer

Model:

SLHY1.2

1.Mixing time 3-6min,0.5T/batch

2.W-shaped barrel can add a variety of liquid, running is

very smooth, the mixing ability is strong, the mixing time

should be 90-180 s, coefficient of variation is ≤ 5% ,

up to 3% or less.Big door at the bottom with the pneumatic discharging with few remaining and small power consumption,not leak

3.Driven: chain driven

4.Motor:china brand

5.Penumaticl gate valve to discharging

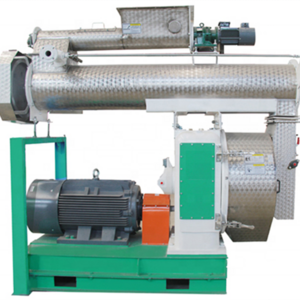

Feed pellet making machine

Model:SZLH320

1.Capacity:1.5-2T/H, feed diameter:3-8 mm

2.feed mash moisture is not more than 15%, temperature is aobut 64~85℃ and humidity is about 14~16% throgh the conditioner.

3.Motor: china brand, drived by motor

4.Roller is made of carbon steel, ring die is made of alloy steel

5.feed speeder is adjustable with variable pitch to prevent anti-arch caking..Variable pitch blades,not blocking raw material, discharging mouth with double helix.

6.Single shaft paddle type to use the steam to sterilize and gelatinization for improve the feed quality .

Cooling machine

Model:SKLN1.4

2.capacity:2-3t/h

3.Body is made of 2 mm thick Q235 steel, rack is made of 8# channel steel

4.driven: Eccentric connection, slide valve type structure

5.Cooling time:6-15 min,cooling down to room temperature: +3-5℃

Pre-Sales Service

* Inquiry and consulting support.

*Solution for customer demand.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1T/H feed pellet production line

91.8% Response Rate

10T/H feed pellet making line

91.8% Response Rate

1-5T/H floating fish feed line

91.8% Response Rate

Shandong Double Crane Machinery Manufacture Co.,Ltd. is located in economical and technological development zone,Leling city,Shandong province,very close to the expressway from Beijing to Shanghai.

Our company is the high and new technological enterprise dedicated to manufacture feed pellet machines to worldwide users.

Sticking to the product developing ideas of simplicity,perfection,quality and innovation,we have been

always focused on designing and manufacturing feed pellet machines since the foundation in 2005.We had cooperated with domestic famous universities like Shandong University, Jinan University and Shandong Agricultural University in feed pellet production line since 2008.We had obtained more than 30 patents and successfully developed 8 series of products,including 60 different kinds of machines.

In the feed pellet industry ,we had achieved advanced level in man-machine design,functional design, automatic control and user experience and became the professional pellet mill manufacturer in China.

We have strong competitive advantages in feed production line with the capacity of 1-30 tph . Until now,we had installed more than 1200 setsof machines worldwide.

R:Our company is manufacturer and public company,we have been specialized in this field more than ten years.

our company's factory covers an area of 67000 square meters,registered capital 60 Million RMB.Located in Dezhou city,Shandong Province.

2.How can we promise the equipment quality?

R:Our company pass European Union GS Safety Certification,ISO9001 Quality Management System Certification, Chinese Credit Enterprise Association, AAA Quality Credit Enterprise Member, Well-known Trademarks In China.We have professional R&D and production team can promise all equipment is qualifyed befor

deliver to customer.

3.If we want to establish a feed production line,can you help us?

R:Yes,our company can provide service of free design,training,guidance,onsite installation,and debugging.

Only need customer tell us which type animal feed do you want to produce,production capacity demand,

we will recommend you the best

design and offer.