Matt, Alistair and Katie from UK: Very satisfied with our samples quality

- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

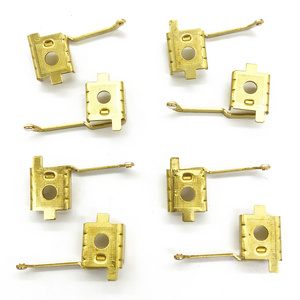

brass stamping, brass stamping blank, brass terminal stamping

-

Size:

-

Custom based on drawing or sample

-

Material:

-

iron,carbon steel,stainless steel,copper,brass,bronze,aluminum,etc

-

Surface treatment:

-

zinc/nickel/tin/chrome/PVD plated,anodise,polish,powder coat,etc

-

MOQ:

-

3000pcs

-

Lead time:

-

15-25days

-

Certifications:

-

ISO9001:2018/IATF16949/RoHS

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yubiao

-

Model Number:

-

Custom Made

-

Product Name:

-

brass stamping, brass stamping blank, brass terminal stamping

-

Size:

-

Custom based on drawing or sample

-

Material:

-

iron,carbon steel,stainless steel,copper,brass,bronze,aluminum,etc

-

Surface treatment:

-

zinc/nickel/tin/chrome/PVD plated,anodise,polish,powder coat,etc

-

MOQ:

-

3000pcs

-

Lead time:

-

15-25days

-

Certifications:

-

ISO9001:2018/IATF16949/RoHS

1. Material: carbon steel, stainless steel,iron,aluminum 6061,6063,7075, brass, copper, bronze,POM,nylon,PMMA,etc

2. Finish: anodizing different colors, brush, sandblast,polish, painting, powder coat, galvanise,nickel/tin/chrome/copper plating, etc

3.Shape and size: Custom according to customer's design

4. Certification: ISO9001, IATF16949, ROHS

|

Product Name

|

Custom precision brass stamping, brass stamping blank, brass terminal stamping with IATF16949 passed

|

|

Available Materials

|

Metal Parts: aluminum,steel,brass,copper,iron, etc.

Plastic Parts: PC, PP, ABS, PMMA, PA, POM, PC+ABS, rubber, etc. |

|

Surface treatment

|

Anodizing,sandblast,brush,powder coat, oil painting, polishing, PVD/CVD coating, galvanized, electroplating, plating(nickle,silver,gold...), spraying, laser etching and so on

|

|

Drawing Format

|

DWG/DXF, IGS/STP/STEP, PDF, etc.

|

|

Lead time

|

15~30 days after confirming samples

|

|

Shipment term

|

FOB,CIF,EXW by sea/air, by express( DHL/UPS/TNT/FedEx)

|

|

Certificate

|

ISO9001:2015,ROHS,IATF16949

|

|

Manufacturing Type

|

Auto lathe,cnc lathe,drilling machine,cnc milling machine

stamping machine,wire cutting machine Universal spring machine, thread rolling machine,taping machine,automatic knurling machine,head molding machine,thread chipping machine cleaning machine grinding machine |

High quality custom cnc lathe/milling parts

30 sets auto lathe machines

20 sets cnc milling center machines

15 sets cnc lathe machines

High quality custom stamping parts( contact/clip/bracket)

50 sets stamping machines

5 sets wire cutting machines

Own mould design and making department

High quality custom extension/compression/torsion spring, special spring,wire clip

15 sets universal spring machines

CNC lathe machines

CNC milling machines

Auto lathe machines

Stamping/punching machines

Common packing way : Inner polybag,outer box.

Special package: pearl cotton,styrofoam,bucket, pallet, custom box,blister,etc

1. Packing with custom box

2. Packing with pallet

3. Packing with with plastic bucket

4.Packing with with styrofoam

5. Packing with pearl cotton

6. Packing with film and strap

We passed ISO9001:2008/ IATF16949/SGS/RoHS/Heavy element certificate.

Olle from Sweden:Nice and friendly partner

Larry from USA: Appreciated with our service and sastified with our factory.

Q: Are you trading company or manufacturer ?

A: We are factory since 2003, specizlied in various metal parts, such as spring, hook, shaft, stamping part, auto lathe part, cnc part,etc.

Q: How does your company handle with customer's complaints?

A: The policy for us to handle with customer's complaint is CUSTOMER FIRST.

1) After get customer's complaints, we will inform all our related people, such as production manager, engineer, quality people and understand the whole condition and find out the reasons.

2) We will report to customer the reasons and solutions.

3) Then to negotiate with customer and find the acceptable solution which both agreed.

Q: How does your company control product quality?

A: First, we will prepare samples for customer confirm. Second, after get the confirmation from customer. we will have a meeting with production manager, quality people, engineer to discuss the issues which occured in samples production and estimate whether there is any problem may appeared in mass production as well as how to avoid it. Third, we have IQC to inspect the coming material from size to surface requirement, and will release pass label if acceptable. Forth, quality people will inspect the first few piece parts after debug machine. Fifth, FQC will inspect parts in every 2 hours. Sixth, FQC will inspect the finished parts before packing to ensure no defect parts delivered to customers.

Q: What is your terms of payment ?

A: T/T,paypal,ali-pay,west union,cash, 30% deposit and 70% balance pay before delivery, or can be negotiable for big amount.