- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

E.P

-

Voltage:

-

220v/380v/400v/415v

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

186*145*170(cm)

-

Name:

-

Hydraulic Shisha Charcoal Press Machine

-

Finished Products:

-

Shisha Charcoal Briquettes

-

Application:

-

Shisha Charcoal Briquetting

-

Pressure type:

-

Hydraulic Pressure

-

Power:

-

15+0.75kw

-

Capacity:

-

49pcs/time, 4times/min

-

Dia. of shisha:

-

20-50mm

-

Final product shape:

-

Square or Round

-

Raw Material:

-

charcoal, coal, coke, coconut shell, bamboo, rice husk, sawdust

Quick Details

-

Warranty:

-

1 Year

-

Core Components:

-

Moror

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

E.P

-

Voltage:

-

220v/380v/400v/415v

-

Weight:

-

2000 KG

-

Dimension(L*W*H):

-

186*145*170(cm)

-

Name:

-

Hydraulic Shisha Charcoal Press Machine

-

Finished Products:

-

Shisha Charcoal Briquettes

-

Application:

-

Shisha Charcoal Briquetting

-

Pressure type:

-

Hydraulic Pressure

-

Power:

-

15+0.75kw

-

Capacity:

-

49pcs/time, 4times/min

-

Dia. of shisha:

-

20-50mm

-

Final product shape:

-

Square or Round

-

Raw Material:

-

charcoal, coal, coke, coconut shell, bamboo, rice husk, sawdust

Related Products

Product Description

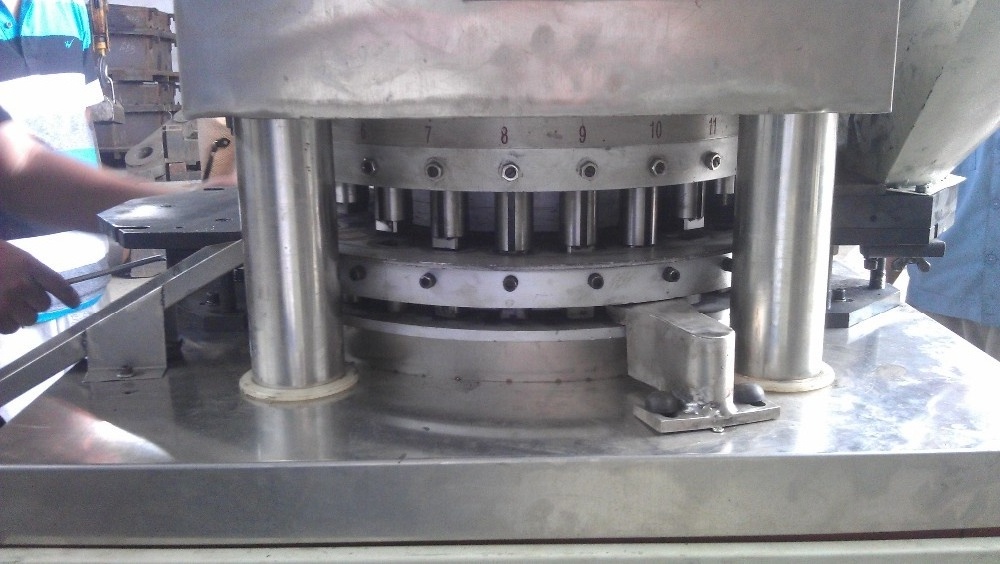

Hydraulic shisha charcoal briquette press machines

are mainly used to make cubic shisha charcoal briquettes. The finished shisha charcoal briquettes are hard and high-density. Besides, cubic shisha charcoal briquettes can burn for a long time.

Briquetting section

Hydraulic pump

Mesh belt conveyor

|

Model

|

HSPY25

|

HSPY49

|

|

power

|

15+0.75kw

|

15+0.75kw

|

|

Capacity

|

6400pcs/h

|

12600pcs/h

|

|

Diameter of briquettes(mm)

|

25*25*(15-25)

|

25*25*(15-25)

|

|

Dimension(cm)

|

186*145*170

|

186*145*170

|

|

Weight(kg)

|

1900

|

2000

|

Features

1- Protective Cover

The briquetting section is protected by the shield covers to prolong the service life of the shisha briquette press machine;

2- Obervation

There are transparent observation windows on the both sides of the briquetting machine, which makes it convenient to monitor the production condition;

3- Electric Cabinet

The power distribution cabinet is installed on the lower left of the left observation window. In this way, you can inspect the distribution cabinet conveniently;

4- Integrated Control Panel

Control panel: Touch screen operation system (auto mode and manual mode), easy to operate;

5- Automatic lubrication device

Equipped with a lubrication system that can lubricate the guiding columns automatically and regularly.Equipped with a lubrication system that can lubricate the guiding columns automatically and regularly.

Mould

The mould of E.P hydraulic shisha charcoal briquette making machine are of three layers. The upper layer is 30mm thick; the middle layer is 70mm thick; the lower layer is 30mm thick. Thus, our mould is durable, and its service life is up to 12-15 months. The mould is customizable.

Shisha charcoal production line

We have A wealth of project experience and can provide complete technical guidance and integrated installation services.

A shisha charcoal briquette production line consists of rotary carbonation furnace, roller crusher, spiral mixer, shisha charcoal briquette making machine, drying machine and several conveyors.

Shisha charcoal briquette machine

Hydraulic shisha charcoal briquette making machines are mainly used to make high-quality cubic shisha charcoal briquettes.

Heat Pump Dryer

The drying machine is powered by electricity, so it will not cause any pollution to environment. Clean, convenient and safe drying equipment.

Finished Products

The finished shisha charcoal

Briquette

produced by this machine are with high density, perfect shape, good appearance. Meanwhile, it is easy for combustion, no smell and long burning time.

Certifications

Why choose us

Our Advantages

1. We have a wealth of project experience and can provide complete technical guidance.

2. Provide integrated installation and complete guidance services

Strong Technical Team

Customized service:

customize equipment according to your requirements.

Installation service: send our workers to your country to install the production line.

Installation service: send our workers to your country to install the production line.

Packaging & Shipping

Packaging Specification:

Outside Package : Wooden Packing as Exported Standard.

Inner Package : Stretch Film

About Shipping

We can be responsible for the shipping according to the customers's requirments to ship the machines by sea, express or air. Besides, we can cooperate with your agent if you have shipping forwarder in China.

Hot Searches