Extend the flue gas process, enhance heat transfer.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

5.30*2.65*3.3m

-

Weight:

-

2T

-

Product name:

-

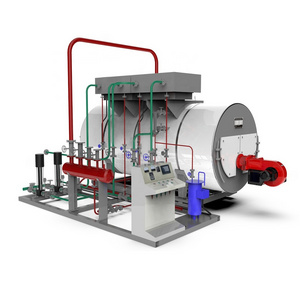

Steam boiler industrial gas steam boiler 2000kgh

-

Application:

-

Industrial Production

-

Capacity:

-

0.5t/h-20t/h

-

Fuels:

-

gas, oil

-

Stam temperature:

-

194

-

Warranty Period:

-

1 year

-

Heat efficient:

-

85%

-

Type of boiler:

-

Vertical boiler

-

Medium:

-

water

-

Application Field:

-

Papermaking Industry

Quick Details

-

Core Components:

-

FIRE TUBE

-

Steam Production:

-

0.5t/h-20t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

5.30*2.65*3.3m

-

Weight:

-

2T

-

Product name:

-

Steam boiler industrial gas steam boiler 2000kgh

-

Application:

-

Industrial Production

-

Capacity:

-

0.5t/h-20t/h

-

Fuels:

-

gas, oil

-

Stam temperature:

-

194

-

Warranty Period:

-

1 year

-

Heat efficient:

-

85%

-

Type of boiler:

-

Vertical boiler

-

Medium:

-

water

-

Application Field:

-

Papermaking Industry

1. Agriculture: Breeding, greenhouse planting, seed factory.

2. Chemical industry: Fertilizer Plant, refinery, feed factory, coating factory, plastic factory, glass factory.

3. Manufacturing: Paper Mill, textile factory, food factory, shoe factory, ceramic factory furniture factory.

4. Construction Industry: Highway Use, site use.

5. Others: Accommodation and catering, bath cente, hotel, disinfection of medical instruments and clothing.

3. Manufacturing: Paper Mill, textile factory, food factory, shoe factory, ceramic factory furniture factory.

4. Construction Industry: Highway Use, site use.

5. Others: Accommodation and catering, bath cente, hotel, disinfection of medical instruments and clothing.

|

Model / Item

|

Rated evaporation capacity

|

Rated steam pressure

|

Rated steam temperature

|

Designed heat efficient

|

Fuel consumption

|

|

|

|

|

|

|

|

|

Oil

|

Gas

|

|

|

Unit

|

t/h

|

Mpa

|

℃

|

%

|

Kg/h

|

Nm3/h

|

|

|

WNS1

|

1

|

1

|

184

|

95

|

73

|

88

|

|

|

WNS2

|

2

|

1.25

|

194

|

95

|

140

|

170

|

|

|

WNS3

|

3

|

1.25

|

194

|

95

|

207

|

252

|

|

|

WNS4

|

4

|

1.25

|

194

|

95

|

278

|

334

|

|

|

WNS6

|

6

|

1.25

|

194

|

95

|

412

|

463

|

|

|

WNS8

|

8

|

8

|

194

|

95

|

535

|

633

|

|

|

WNS10

|

10

|

1.25

|

194

|

95

|

687

|

771

|

|

|

WNS15

|

15

|

1.25

|

194

|

95

|

969

|

1156

|

|

|

WNS20

|

20

|

1.25

|

194

|

95

|

1292

|

1541

|

|

|

Name

|

Hydrogen Boiler for Heating waste Oil induction heating boiler

|

|

Pressure

|

0.7Mpa-2.5Mpa

|

|

Fuel

|

Natural gas, lpg, Light Oil, Diesel, Heavy oil,dual fuels

|

|

Power

|

0.5t/h-20t/h 0.35mw/h - 14mw/h

|

Description:

WNS series horizontal internal-combustion furnace is pan-shell type horizontal three-return fuel oil boiler developed by absorbing domestic, foreign advanced technology and experience. It runs automatically. After the burner atomizes fuel, the produced torch is full of the wave-type boiler inner and transfers radiation heat through inner wall. This is the first return. The high-temperature smoke gas produced during burning accumulates in burning room and turns to the second return (screw smoke pipe bundle area). After conversion heat change, smoke gas's temperature reduces gradually and then it goes into the front smoke case; And turns into the third return (light pipe bundle area); Finally, it flows into chimney through rear smoke case.

Three passes structure

Wet back structure

Lower the temperature of the rear tube to prevent cracking.

Spirally corrugated tube

Strengthening heat transfer, eliminaating welding stress.

Corrugated Furnace

Big size corrugated furnace, which can increase the heat surface area, and satisfying free expansion of the furnace pipe after heating.

Big Door Opening

Easy to open, easy to clean dust.

2tph steam boiler in UZ

4tph diesle steam boiler in Kenya

25tph steam boiler in Myanmar

Vertical coal fired steam boiler in Chile

3mkcalph coal fired thermal oil boiler in Vietnam

2tph biomass boiler in Togo

1200kw diesel fired thermal oil boiler in Zimbabwe

2tph coal steam boiler in Philippines

10tph steam boiler in Ukraine

25tph coal fired steam boiler in Bangladesh

Electrical steam boiler in Ethiopia

2x12m wood treatment equipment in Zambia

Q1:How can you get the best price quickly?

1) We need to know the boiler capacity, the fuel and the steam pressure you need, and then we can confirm the boiler model.

2) Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if

you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

1) We need to know the boiler capacity, the fuel and the steam pressure you need, and then we can confirm the boiler model.

2) Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if

you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

Q2: Why should you believe our boiler quality?

1) Strength calculation report with applied materials information;

1) Strength calculation report with applied materials information;

2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

3) 100% X-ray inspection(welding seam): ensure the quality of entire boiler;

4) Hydrostatic test: ensure the standard working pressure and safety;

5) Third-party inspection report:By Henan Boiler Inspection Institute;

6) Passed ISO:9001/BV/ CE and SGS certificate.

Q3: What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some preparation for installation; If necessary, our expert will fly to your local place. The experts will responsible for guiding installation and commissioning.

But the buyer will be in charge of:

1) The round air-tickets costs from Zhengzhou city to your project site.

2) Board and lodging of seller's workers for entire period at the end user's site.

3) Service fee for guiding engineer:100$/day/person.

Q4:What is the using life of your boiler?

A:Normally the boiler is designed for 15-25 years life span.

3) 100% X-ray inspection(welding seam): ensure the quality of entire boiler;

4) Hydrostatic test: ensure the standard working pressure and safety;

5) Third-party inspection report:By Henan Boiler Inspection Institute;

6) Passed ISO:9001/BV/ CE and SGS certificate.

Q3: What about the installation and Commissioning?

After you receive the boiler, we will guide you to make some preparation for installation; If necessary, our expert will fly to your local place. The experts will responsible for guiding installation and commissioning.

But the buyer will be in charge of:

1) The round air-tickets costs from Zhengzhou city to your project site.

2) Board and lodging of seller's workers for entire period at the end user's site.

3) Service fee for guiding engineer:100$/day/person.

Q4:What is the using life of your boiler?

A:Normally the boiler is designed for 15-25 years life span.

Hot Searches