- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.074

-

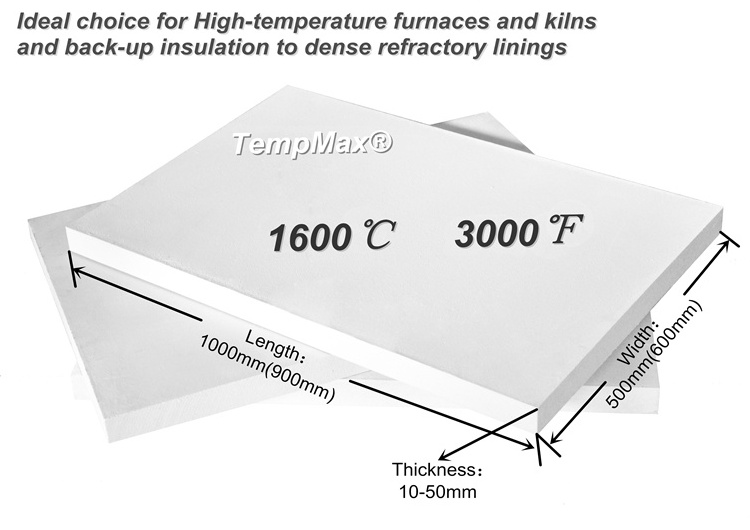

Thickness:

-

25/50mm

-

Width:

-

610mm

-

Length:

-

900/1000mm

-

Working Temperature:

-

1600℃

-

Shrinkage (1800℉, 3h):

-

-3%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Alumina Fiber Board

-

Brand Name:

-

TempMax

-

Product name:

-

Polycrystalline Mullite Fiber Board

-

Raw material:

-

Polycrystalline Mullite Fiber Wool

-

Keyword:

-

Polycrystalline Alumina Fibre Board

-

Package:

-

Carton Box

-

Sample:

-

Avaliable

-

Feature:

-

Thermal Shock Resistance

-

Advantage:

-

Low Thermal Conductivity

-

Product Keywords:

-

LUYANG PCW Board

-

Material:

-

Alumina Fiber Cotton

-

Manufacturer:

-

Luyang

Quick Details

-

Chemical Composition:

-

Al2O3

-

Ultimate Strength (≥ MPa):

-

0.2

-

Fiber Diameter:

-

3-5μm

-

Thermal Conductivity:

-

0.074

-

Thickness:

-

25/50mm

-

Width:

-

610mm

-

Length:

-

900/1000mm

-

Working Temperature:

-

1600℃

-

Shrinkage (1800℉, 3h):

-

-3%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Alumina Fiber Board

-

Brand Name:

-

TempMax

-

Product name:

-

Polycrystalline Mullite Fiber Board

-

Raw material:

-

Polycrystalline Mullite Fiber Wool

-

Keyword:

-

Polycrystalline Alumina Fibre Board

-

Package:

-

Carton Box

-

Sample:

-

Avaliable

-

Feature:

-

Thermal Shock Resistance

-

Advantage:

-

Low Thermal Conductivity

-

Product Keywords:

-

LUYANG PCW Board

-

Material:

-

Alumina Fiber Cotton

-

Manufacturer:

-

Luyang

Products Description

TEMPMAX

®

ALUMINA FIBER BOARD /

Polycrystalline Wool Board

TempMax

®

board is manufactured in a wet forming process using TempMax

®

bulk and binders. TempMax

®

board has excellent thermal stability at very high operating temperatures. TempMax

®

board can reduce energy costs and cycling times due to high insulating capability, as well as serving to protect refractory surfaces from thermal shock and chemical attack.

Features

Excellent thermal shock resistance

Can be machined,cut and shaped easily

High rigidity and light weight

Low thermal conductivity

Low heat storage

Can be machined,cut and shaped easily

High rigidity and light weight

Low thermal conductivity

Low heat storage

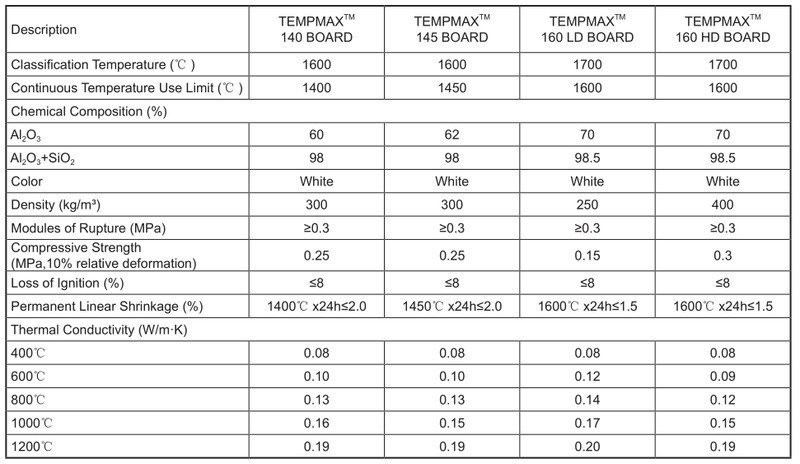

Typical Parameters

|

Description

|

TEMPMAX

®

140 BOARD

|

TEMPMAX

®

145 BOARD

|

TEMPMAX

®

160 LD BOARD

|

TEMPMAX

®

160 HD BOARD

|

||||

|

Classification Temperature (℃ )

|

1600

|

1600

|

1600

|

1600

|

||||

|

Continuous Temperature Use Limit (℃ )

|

1400

|

1450

|

1600

|

1600

|

||||

|

Chemical Composition (%)

|

|

|

|

|

||||

|

Al2O3

|

60

|

62

|

70

|

70

|

||||

|

Al2O3+SiO2

|

98

|

98

|

98.5

|

98.5

|

||||

|

Color

|

White

|

White

|

White

|

White

|

||||

|

Density (kg/m³)

|

300

|

300

|

300

|

300

|

||||

|

Modules of Rupture (MPa)

|

≥0.3

|

≥0.3

|

≥0.3

|

≥0.3

|

||||

|

Compressive Strength

(MPa, 10% relative deformation)

|

0.25

|

0.25

|

0.25

|

0.25

|

||||

|

Loss of Ignition (%)

|

≤8

|

≤8

|

≤8

|

≤8

|

||||

|

Permanent Linear Shrinkage (%)

|

1400℃ x24h

≤2.0

|

1450℃ x 24h

≤2.0

|

1600℃ x 24h

≤2.0

|

1600℃ x 24h

≤2.0

|

||||

|

Thermal Conductivity (W/m·K)

|

|

|

|

|

||||

|

400℃

|

0.08

|

0.08

|

0.08

|

0.08

|

||||

|

600℃

|

0.10

|

0.10

|

0.12

|

0.09

|

||||

|

800℃

|

0.13

|

0.13

|

0.14

|

0.12

|

||||

|

1000℃

|

0.16

|

0.15

|

0.17

|

0.15

|

||||

|

1200℃

|

0.19

|

0.19

|

0.20

|

0.19

|

||||

Application

|

Typical Applications

|

Typical Applications

|

|

|

1

|

High-temperature laboratory

|

|

|

2

|

High-temperature furnaces and kilns

|

|

|

3

|

Aerospace industry

|

|

|

4

|

Back-up insulation to dense refractory linings

|

|

|

5

|

Expansion joints

|

|

Hot Searches