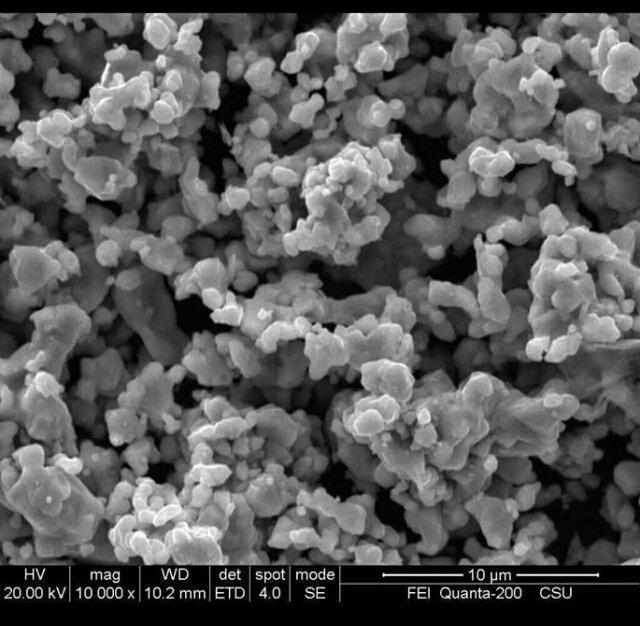

Nano diamond powder has a wide range of applications in industries such as aerospace, aircraft manufacturing, precision machinery, optical instruments, and automotive manufacturing;

1. The most ideal polishing agent can achieve atomic level polishing surfaces. Especially used for precision machining and polishing of various hard material products such as fine ceramics, integrated circuit chips, various gemstones, ferrite magnetic heads, quartz sheets, superhard alloys, optical lenses, etc;

2. Electroplated and non electroplated coatings with high hardness and wear resistance;

3. Metal composite materials with high hardness and wear resistance;

4. Low friction, low wear, high load, and long life lubrication systems (such as lubrication for various cylinders) and super lubricating oils.

5. PTFE based composite materials with high wear resistance and good lubricity;

6. It is an irreplaceable material for producing polycrystalline diamond and diamond thin films.

7. It is the main material for producing nano diamond thermal penetration.

8. Can be used for metal modification.Nano diamond can be used for ultra mirror polishing of wire drawing molds, as well as for mirror polishing of crystals and silicon wafers, with excellent wear resistance, corrosion resistance, and thermal conductivity; Has ultra-high purity, ultra smooth polishing effect, and the main impurity content is below 1ppm; The surface roughness is less than 0.8nm.