- Product Details

- {{item.text}}

Quick Details

-

Size:

-

10010*2555*3890

-

Place of Origin:

-

Hebei, China

-

Tank volume:

-

35000L-38000L

Quick Details

-

Type:

-

Semi-Trailer

-

Max Payload:

-

>30000 kg

-

Brand Name:

-

isuzu hono

-

Size:

-

10010*2555*3890

-

Place of Origin:

-

Hebei, China

-

Tank volume:

-

35000L-38000L

Product Overview

Chemical

tanker truck

Our company, after years of development and growth, has emerged as a leader in the global specialty vehicle manufacturing industry. We are a leading figure in the production of vehicles for transporting flammable and explosive liquids, corrosive liquids, oxidizing liquids, chemical lined plastic tankers, and chemical liquid storage tanks, both domestically and internationally. The company adheres to the business philosophy of “professional manufacturing, creating quality products, and mutual development.” We strictly follow the national standards of the People’s Republic of China, such as “GB 18564.1-2019 Road Transport Liquid Dangerous Goods Tank Vehicles Part 1: Technical Requirements for Metal Atmospheric Tanks,” “GB 18564.1-2019 Road Transport Liquid Dangerous Goods Tank Vehicles Part 2: Technical Requirements for Non-Metal Atmospheric Tanks,” and “GB7258-2017 Motor Vehicle Operating Safety Technical Conditions” in our design and production. We also meet the requirements of “Operational Truck Safety Technical Conditions (JT/T1178.1-2018)” and are listed in the road transport vehicle standard models..

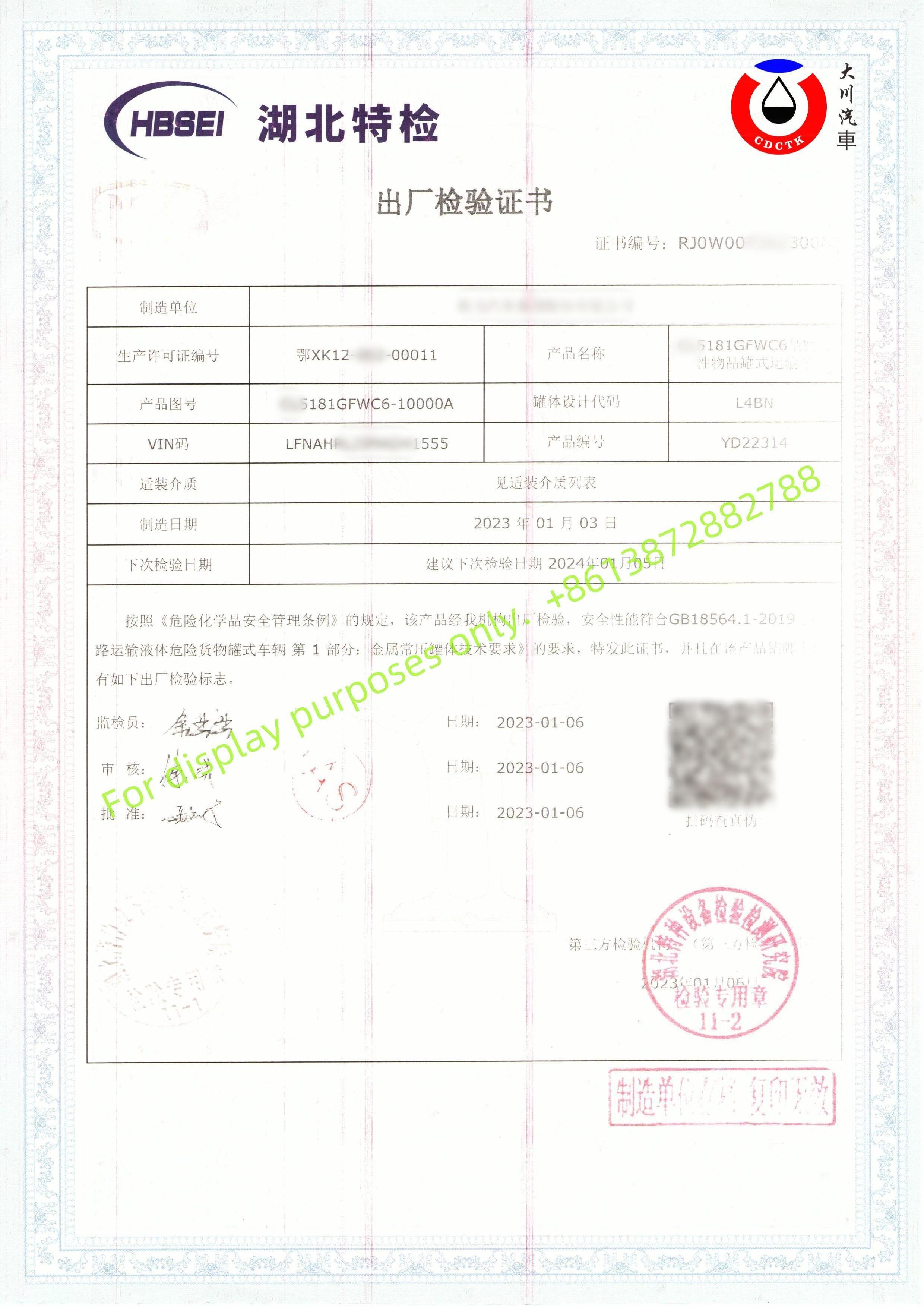

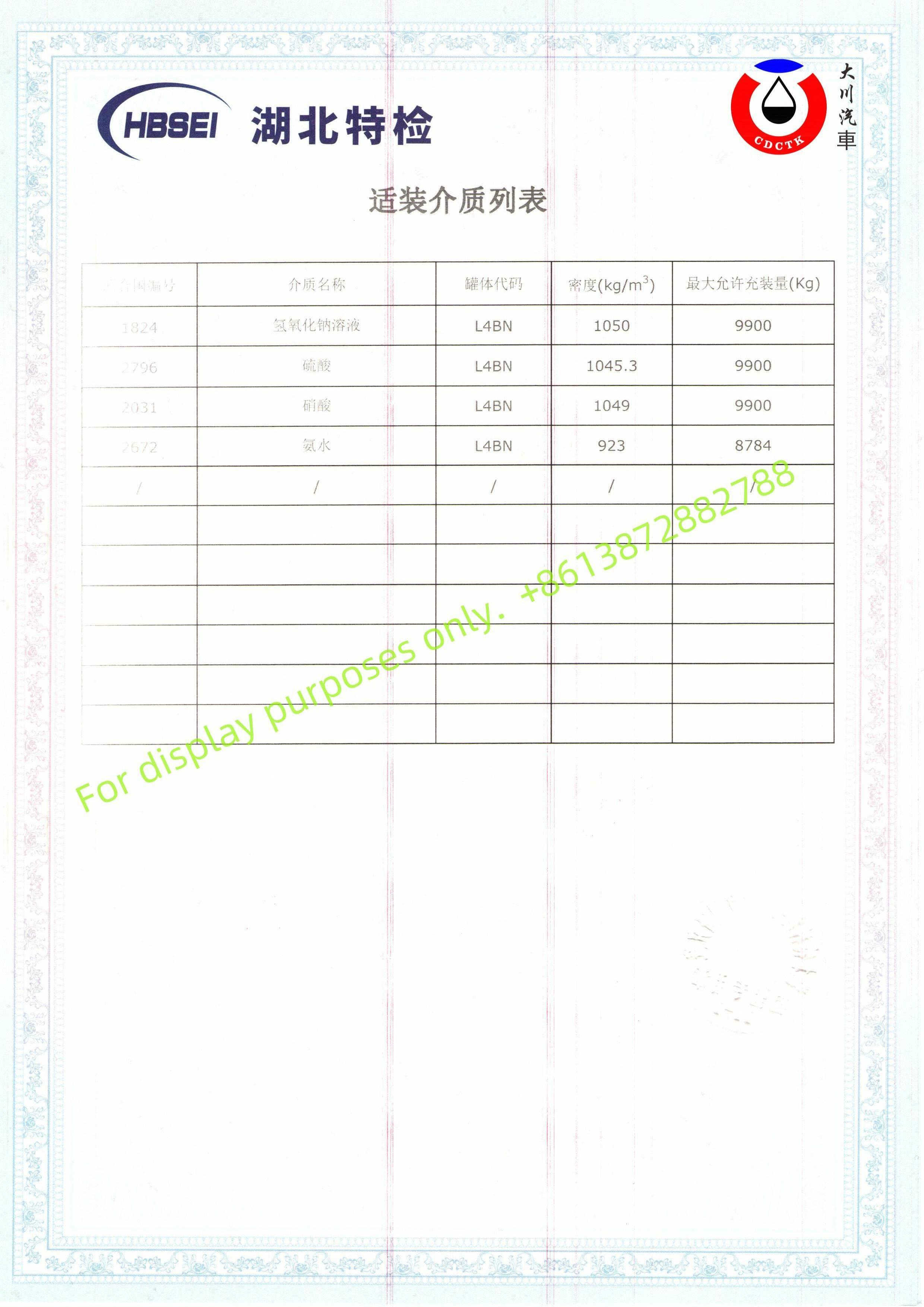

The tank inspection report below is from the China National Accreditation Service for Conformity Assessment (CNAS).

Main Business Dedicated to the research, development, production and manufacture of hazardous chemical transport vehicles, storage equipment and parts. Relying on a series of special vehicle chassis at home and abroad, we tailor-make tanks for different mediums, cargo chemical properties, types, concentrations, ambient temperatures, vehicle procurement costs, carrying capacity, corrosion allowance and other requirements. Materials used for manufacturing tanks include carbon steel, manganese steel, aluminium alloy, titanium alloy, aluminium, 304 stainless steel, 316 stainless steel, C4 steel, steel lined with plastic (polyethylene) (polypropylene) (Teflon), steel lined with rubber, plastics, ceramics, glass fibre, carbon fibre, foam insulation and so on.

Class 3 flammable substances (FL type vehicles): Acetone, adhesives, paints, varnishes, alcohols, spice products, gasoline, diesel fuel, aviation fuel, heating oil, paraffin, resins, tar, turpentine, ethanol, benzene, butanol, isopropyl alcohol, methanol, octane, etc.

General items: well washing fluids, fracturing fluids, water purifiers, water reducers, cleaning agents, asphalt, hydraulic oils, edible oils, alcohols, milk, various liquid foods, etc.

Service Hotline: +8613872882788 +8613908665755

mail:Yanis@cdctk.com Finne@cdctk.com

PRODUCT SPECIFICATIONS

|

Name of vehicle

|

Oil tank semi-trailer

|

|

Vehicle type

|

CS9301GFW20

|

|

Chassis type

|

|

|

Volume

|

30-55 cubic meters

|

|

Total mass

|

40000Kg

|

|

Quality of equipment (Kg)

|

9000Kg

|

|

Vehicle length

|

10000 ×2550×3900

|

|

Rated load mass (kg)

|

21100,21165

|

|

The engine

|

|

|

Chassis configuration

|

Travelling configuration: complying with GB18564.1-2019 standard; L4BH design code; Fuhua 10-ton axle*2; disc brake*4; brake disc

wear alarm; air suspension; Kemi EBS; steel wheels*12; Linglong 12R22.5 12PR tyres*8; Fuhua 28-ton linkage outriggers; 50 traction pins; Options: BPW axles; drum brakes; mechanical suspension; Wilburco EBS; Knorr-Bremse EBS; aluminium alloy wheels; steel wire tyres or vacuum tyres, 90 towing pins; |

|

tanker configuration

|

Upper end standard configuration (aluminum alloy, stainless steel, carbon steel): according to GB18564.1-2019 standard; gbf design

specification; Circumference tank; Tank material aluminum alloy, SUS304, SUS316 or Q235 carbon steel; The thickness of the cylinder, the thickness of the head Bulkhead 5mm, 6mm, 5mm, 7mm; Rotating head; Through the silo; Bulkhead * 2; The top of the tank is aluminum alloy, stainless steel or carbon steel tank mouth * 2; Stainless steel vacuum valve *1; DN100 aluminum alloy, stainless steel or carbon steel tee pipe *1; DN100 aluminum alloy, stainless steel or carbon steel submarine valve * 1; Submersible valve alarm device; Back end left and right flow DN80 aluminum alloy, stainless steel or carbon steel ball valve Back end *2; Aluminum alloy, carbon steel movable guardrail, rear ladder, tool box, rear bumper, side guard; Aluminum, carbon steel or plastic outlet box *2; Tank body shot blasting treatment; Tank inspection report; Quality assurance certificate; Upper standard Configuration (aluminum alloy): in line with GB18564.1-2019 standard; gbf design specification; Wheel groove; Tank material 5182; 5186 aluminum alloy; The thickness of cylinder head and bulkhead are 6mm, 6mm and 6mm respectively. Rotating head; pass Silos; Bulkhead * 2; The top of the tank has a European standard tank mouth * 3; Aluminum alloy vacuum valve * 1; DN100 Aluminum Alloy tee pipe * 1; DN100 aluminum alloy submarine valve * 1; Submersible valve alarm device; Rear end left and right artesian flow DN80 aluminum alloy ball valve, rear end * 2; A set of European standard (3 European standard tank mouths, 1 submersible valve, 1 Lower oil load, exhaust gas recovery, oil spill probe and socket), lower oil load in the co-cockpit On the side, add the automatic cutting system of the submersible valve, with the static drum; Aluminum alloy movable guardrail; after Ladders, toolboxes, rear bumpers and side protectors are all made of aluminum. Outlet box * 2; Polishing groove; Tank inspection report; Quality assurance certificate; |

Hot Searches