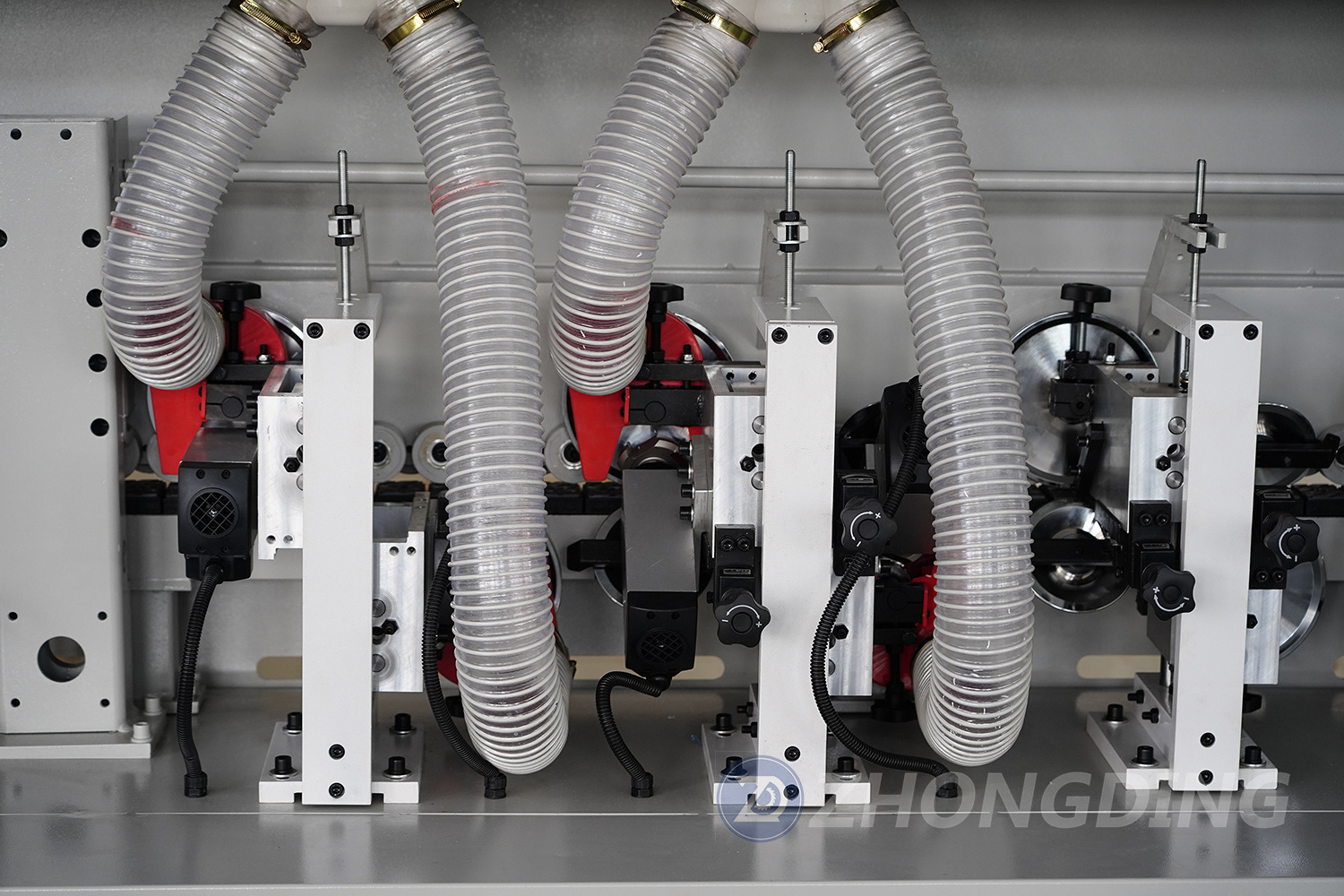

Corner rounding mechanism with two high precision tracking motors to ensure high tracking speed and high trimming speed.

The profile tracking system component is used to match the sun coated film to the jade star on the workpiece during the transportation process and cut (outline) the edges and corners.It can make the end surface of the table more smooth and beautiful.

- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

edge banding

-

After-sales Service Provided:

-

Online support

-

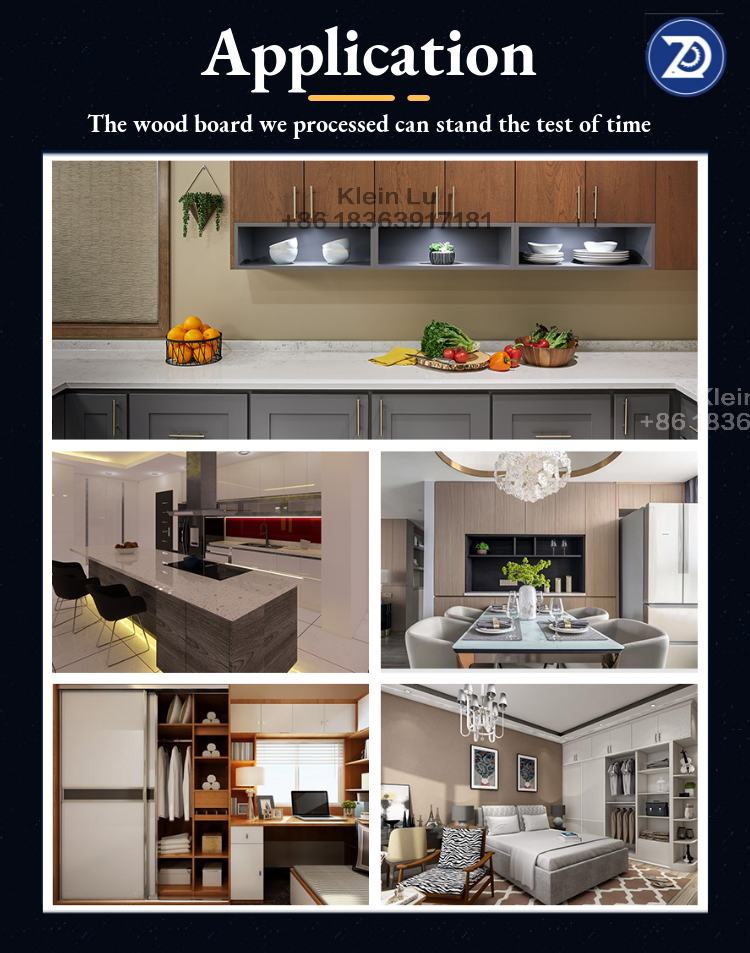

Application:

-

Wood board edge banding

-

Model:

-

ZD800

-

Voltage:

-

Customizable

-

edge band thickness:

-

0.4~3mm

-

wood board thickness:

-

10~60mm

-

Control:

-

PLC Touch screen

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

2000 kg

-

Panel Feed Speed(m/min):

-

18m/min

-

Usage:

-

edge banding

-

After-sales Service Provided:

-

Online support

-

Application:

-

Wood board edge banding

-

Model:

-

ZD800

-

Voltage:

-

Customizable

-

edge band thickness:

-

0.4~3mm

-

wood board thickness:

-

10~60mm

-

Control:

-

PLC Touch screen

kdt nanxing woodworking rubber wood edge banding machine with corner rounding

|

Model NO.

|

ZD800

|

Panel thickness

|

10-60mm

|

|

Working pressure

|

0.6MPa

|

Panel length

|

Min.150mm

|

|

Total power

|

16.5kw

|

Panel width

|

Min.50mm

|

|

Feeding speed

|

13m/min

|

Edge thickness

|

0.4-3mm

|

|

Overall size

|

5900*900*1590mm

|

Weight

|

2650KG

|

kdt nanxing woodworking rubber wood edge banding machine with corner rounding

has 8 Functions :

Pre-milling、Gluing 、End trimming、Rough trimming、Fine trimming、Corner rounding, Scraping、Buffing.

Gluing

The glue pot adopts imported special ball bearing and high hardness and super wear-resistant material glue box, the glue lifting shaft is patented design, CNC processing, to ensure the glue output, uniform daub, the glue surface hit 99.999%, the glue thickness can be controlled at will.

End trimming

The end trimming system is used to cut off the cutting components of the front and rear edge tape. The end trimming device moves through precise linear guides, adopts automatic profiling and high-frequency electrode rapid cutting mechanisms to ensure that the cut surface is flat and smooth.

Rough&Fine trimming

Rough and fine trimming devices are used for trimming and processing the excess edge banding material on the upper and lower parts of the sheet edge banding. It adopts the structure of automatic profiling and high-frequency high-speed motor, etc. To ensure the smoothness of the upper and lower parts of the trimmed board edge.

Scraping

The scrapping is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming, so that the upper and lower parts of the sapwood are smoother and cleaner, and the edges are scraped. Updated scraping mechanism with bigger unit and big copy wheel and V shape blade to get better effect.

Buffing/Polishing

The buffing component polishes the edge and removes the sol residue on the workpiece. The polishing device uses a cotton polishing

wheel to clean the processed plate. The edge-sealing end surface is smoother through polishing. The polishing component used for the upper surface of the workpiece is fixed on workpiece.

wheel to clean the processed plate. The edge-sealing end surface is smoother through polishing. The polishing component used for the upper surface of the workpiece is fixed on workpiece.

Pre-milling

The pre-milling system corrects the plate-type workpiece before pressing the film. The pre-milling device uses double milling cutters to modify the ripple marks caused by the cutting board saw processing to achieve a better edge banding effect.

Corner Rounding

PACKAGE:

LCL SHIPMENT: Use plastic foam protect ,then ply wooden case package.

FCL: If the equipment enough packagewith 20"or 40" container ,will use plastic foam package and wooden pallet.

SHIPPING TERMS:

1. We can arrange the shipping by sea, by air ,by truck and train based on your requirements, but kindly remind the refrigerant gas can't allowed by air ,so you must filling them whenmachine arrive if you choose the air ship.

2. FOB,CNF,CIF,DDU can be accepted.

3. Any port of CHINA we can sent ,if you have other goods will packaged in one container ,we would like to arrange that for you.

LCL SHIPMENT: Use plastic foam protect ,then ply wooden case package.

FCL: If the equipment enough packagewith 20"or 40" container ,will use plastic foam package and wooden pallet.

SHIPPING TERMS:

1. We can arrange the shipping by sea, by air ,by truck and train based on your requirements, but kindly remind the refrigerant gas can't allowed by air ,so you must filling them whenmachine arrive if you choose the air ship.

2. FOB,CNF,CIF,DDU can be accepted.

3. Any port of CHINA we can sent ,if you have other goods will packaged in one container ,we would like to arrange that for you.

Hot Searches