- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LAIZE

-

Working Pressure:

-

0.1~1.0MPa

-

Working Temperature:

-

-20~80°C

-

Working fluid:

-

Clean air

-

Buffer mode:

-

anti-crash cushion

-

Operating Speed:

-

30~500mm/s

-

Operating method:

-

Single Action, Double Action

-

Type:

-

MA

Quick Details

-

Weight (KG):

-

0.4

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LAIZE

-

Working Pressure:

-

0.1~1.0MPa

-

Working Temperature:

-

-20~80°C

-

Working fluid:

-

Clean air

-

Buffer mode:

-

anti-crash cushion

-

Operating Speed:

-

30~500mm/s

-

Operating method:

-

Single Action, Double Action

-

Type:

-

MA

Product Description

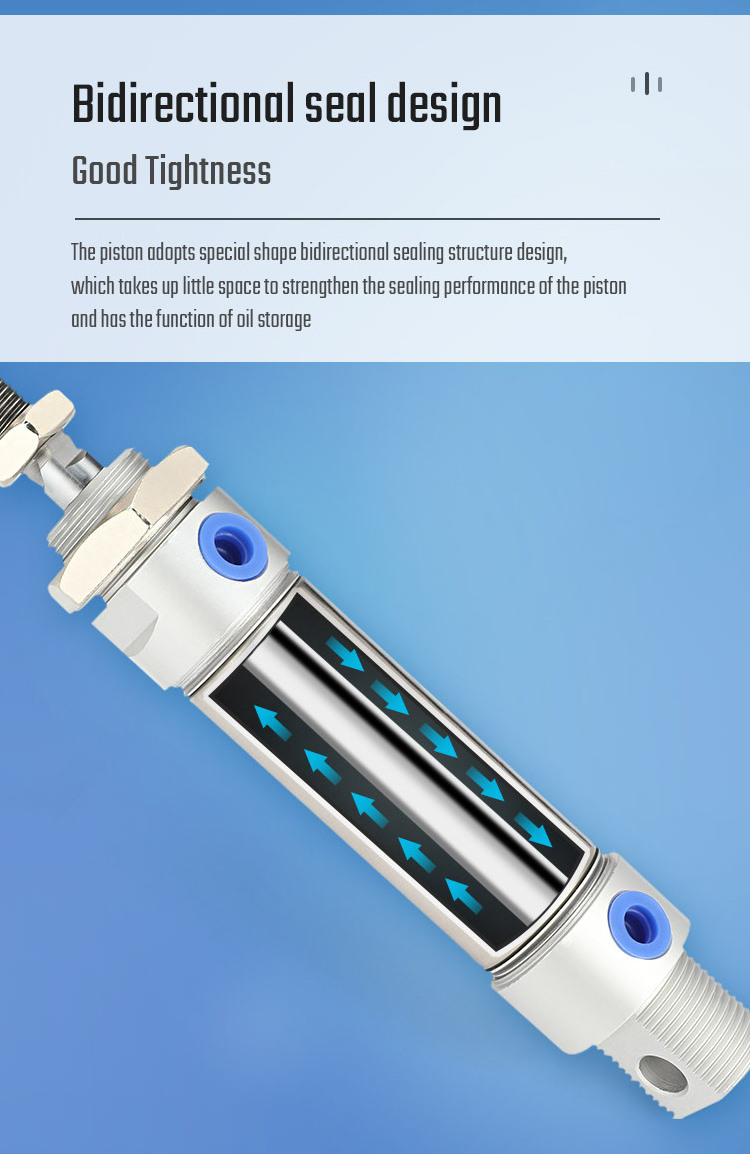

Welcome to Laize MA Series Mini Pneumatic Cylinders, where precision and compact design meet stainless steel durability. Our mini air cylinders, part of the renowned MA Series, are engineered to deliver exceptional performance in a wide range of industrial applications. With a focus on precision control and space efficiency, these mini cylinders excel in tight spaces where every millimeter matters.

What does an air cylinder do?

An air cylinder, also known as a pneumatic cylinder, is a mechanical device that converts compressed air pressure into linear motion or force. It plays a crucial role in various industrial and automation applications. Here's what an air cylinder does and its primary functions:

Linear Motion: Air cylinders are used to generate linear motion, meaning they move in a straight line. When compressed air is applied to one end of the cylinder, it pushes a piston or rod, causing it to extend or retract. This linear motion can be used for tasks such as pushing, pulling, lifting, lowering, and positioning objects or components in a controlled manner.

Force Generation: Air cylinders can generate substantial force, depending on their size and the air pressure applied. This force can be used for tasks like clamping, pressing, and actuating mechanical components in various industrial processes.

Automation: Air cylinders are a fundamental component in pneumatic automation systems. They are often used to control the movement of valves, gates, conveyor systems, robotic arms, and other machinery in factories and manufacturing processes. They contribute to the precise and efficient operation of automated systems.

Control and Regulation: Air cylinders are known for their precise control. By adjusting the air pressure and the design of the cylinder, operators can regulate the speed, force, and position of the cylinder's movement, making them versatile tools for various applications.

Safety: Air cylinders are commonly used in safety applications where a controlled mechanical movement is necessary. For example, they can be used in emergency stop systems, safety gates, and machinery that requires precise and reliable shutdown mechanisms.

How do I know if my air cylinder is bad?

Leaking Air: If you notice a noticeable hissing sound or feel air escaping from the cylinder when it's not supposed to, it's a clear sign of a leak. Leaking air can result from damaged seals, gaskets, or other internal components.

Inconsistent Movement: If the cylinder's movement becomes erratic, jerky, or less smooth than usual, it may indicate internal wear or damage. This can affect the cylinder's ability to perform its intended tasks accurately.

Sluggish or Slow Operation: If the cylinder is operating more slowly than usual or lacks the force it used to provide, it might be a sign of air supply issues, internal friction, or damage.

Excessive Noise: Unusual or loud noises during operation, such as banging or clanking, can be an indication of internal problems, loose parts, or misalignment.

Uneven Wear: Inspect the cylinder's exterior for signs of uneven wear or damage. This can include scratches, dents, or signs of physical stress. These issues can affect the cylinder's performance.

Fluid or Contaminant Presence: If you notice the presence of fluid (e.g., oil) or contaminants (e.g., dirt, debris) around the cylinder or on its components, it can be a sign of a seal breach or contamination that may lead to reduced performance or damage.

Difficulty Maintaining Position: If the cylinder has difficulty holding a specific position or drifts when it should stay stationary, it may indicate internal issues with the seals or valves.

Overheating: An air cylinder that becomes excessively hot during operation could indicate a problem. Overheating can result from inefficiencies in the system or excessive friction within the cylinder.

Loss of Force: If the cylinder has lost its ability to generate the expected force or has a reduced maximum force output.

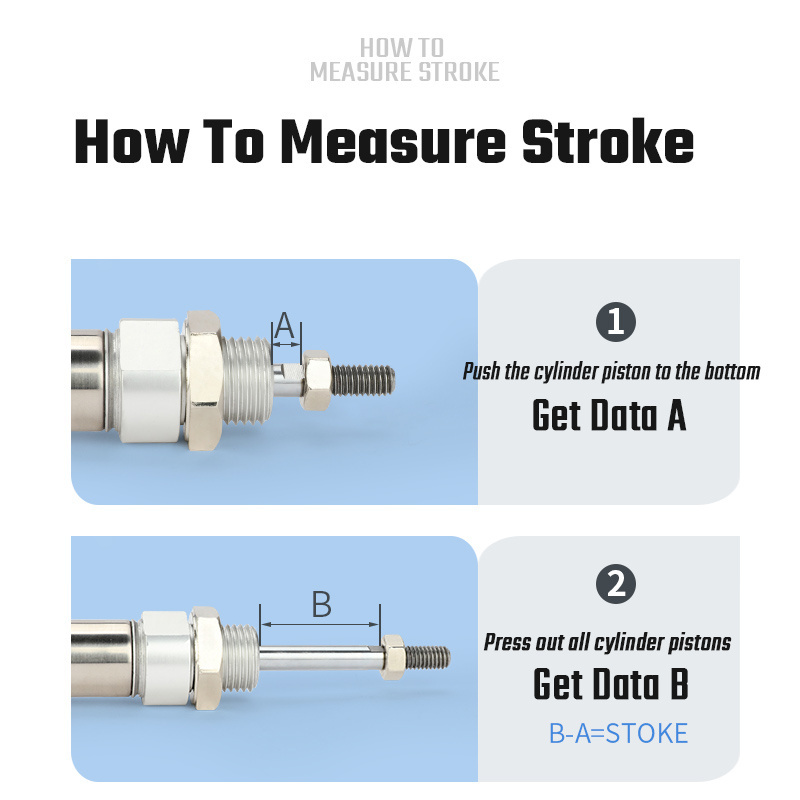

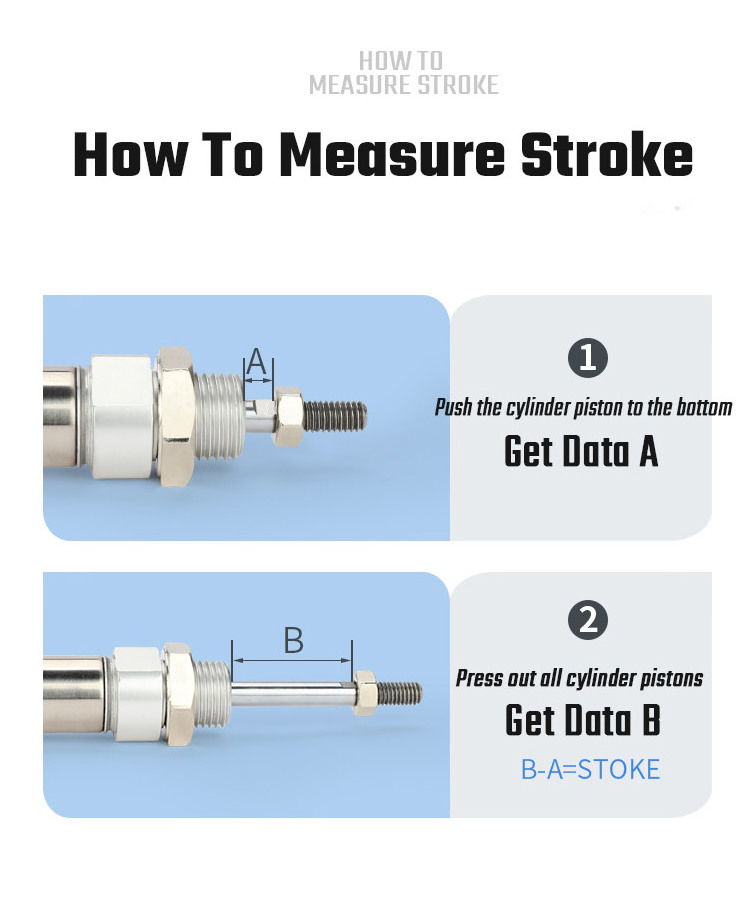

How do you calculate air in a cylinder?

To calculate the amount of air (volume) in a cylinder, you'll need to consider the dimensions of the cylinder and the stroke length (how far the piston or rod travels inside the cylinder). The formula to calculate the air volume in a cylinder is straightforward and is based on the formula for the volume of a cylinder:

Volume = π × (Radius^2) × Stroke Length

Here's how to calculate it step by step:

Measure the cylinder's radius (the distance from the center of the cylinder to its inner wall). If you have the diameter, you can divide it by 2 to get the radius.

Measure the stroke length, which is the distance the piston or rod travels inside the cylinder.

Use the formula: Volume = π × (Radius^2) × Stroke Length

Plug in the values you measured:

Radius (in meters or feet)

Stroke Length (in meters or feet)

Calculate the volume, which will be in cubic meters (m³) or cubic feet (ft³), depending on your units of measurement.

For example, if you have a cylinder with a radius of 0.05 meters (5 centimeters) and a stroke length of 0.2 meters (20 centimeters):

Volume = π × (0.05^2) × 0.2 = π × 0.0025 × 0.2 = 0.00157 cubic meters (m³)

Can you rebuild air cylinders?

Yes, air cylinders can be rebuilt or repaired in many cases, depending on the extent of the damage or wear. Rebuilding an air cylinder typically involves disassembling the cylinder, inspecting its components, replacing any damaged or worn parts, and then reassembling the cylinder. Here are the general steps involved in rebuilding an air cylinder:

Disassembly: Carefully disassemble the air cylinder, following the manufacturer's guidelines or technical documentation. This typically involves removing end caps, seals, and the piston or rod.

Inspection: Thoroughly inspect all components for damage, wear, or signs of corrosion. Common components that may need replacement include seals, o-rings, piston rods, and end caps.

Replacement Parts: Identify the parts that need replacement and obtain the appropriate replacement components from the manufacturer or a reliable supplier. It's essential to use high-quality replacement parts to ensure the cylinder's performance and longevity.

Cleaning: Clean all the components, including the cylinder body, piston, rod, and seals, to remove any dirt, debris, or old lubricant.

Assembly: Carefully reassemble the air cylinder, making sure all components are properly aligned and seated. Apply the appropriate lubricant to the seals and moving parts during assembly.

Testing: After reassembly, test the cylinder to ensure it operates correctly. This may involve checking for leaks, verifying that it moves smoothly, and confirming that it generates the expected force or motion.

Adjustments: If necessary, make any adjustments to the cylinder's settings or air pressure to ensure it functions as required.

Hot Searches