- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JingChi

-

Product Name:

-

Single wheel Knurling tool

-

Model:

-

CH1215R20

-

Process:

-

Straight lines and left or right cross grain

-

Processing Range:

-

5 - 250mm

-

Direction:

-

Right + Left

-

Application:

-

Knurling

-

Usage:

-

Lathe,CNC

-

Certificate:

-

ISO9001

-

OEM:

-

Accept

-

Packing:

-

Carton Box

Quick Details

-

Material:

-

HIGH SPEED STEEL

-

Type:

-

End Mill

-

Finish:

-

Bright(Uncoated)

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JingChi

-

Product Name:

-

Single wheel Knurling tool

-

Model:

-

CH1215R20

-

Process:

-

Straight lines and left or right cross grain

-

Processing Range:

-

5 - 250mm

-

Direction:

-

Right + Left

-

Application:

-

Knurling

-

Usage:

-

Lathe,CNC

-

Certificate:

-

ISO9001

-

OEM:

-

Accept

-

Packing:

-

Carton Box

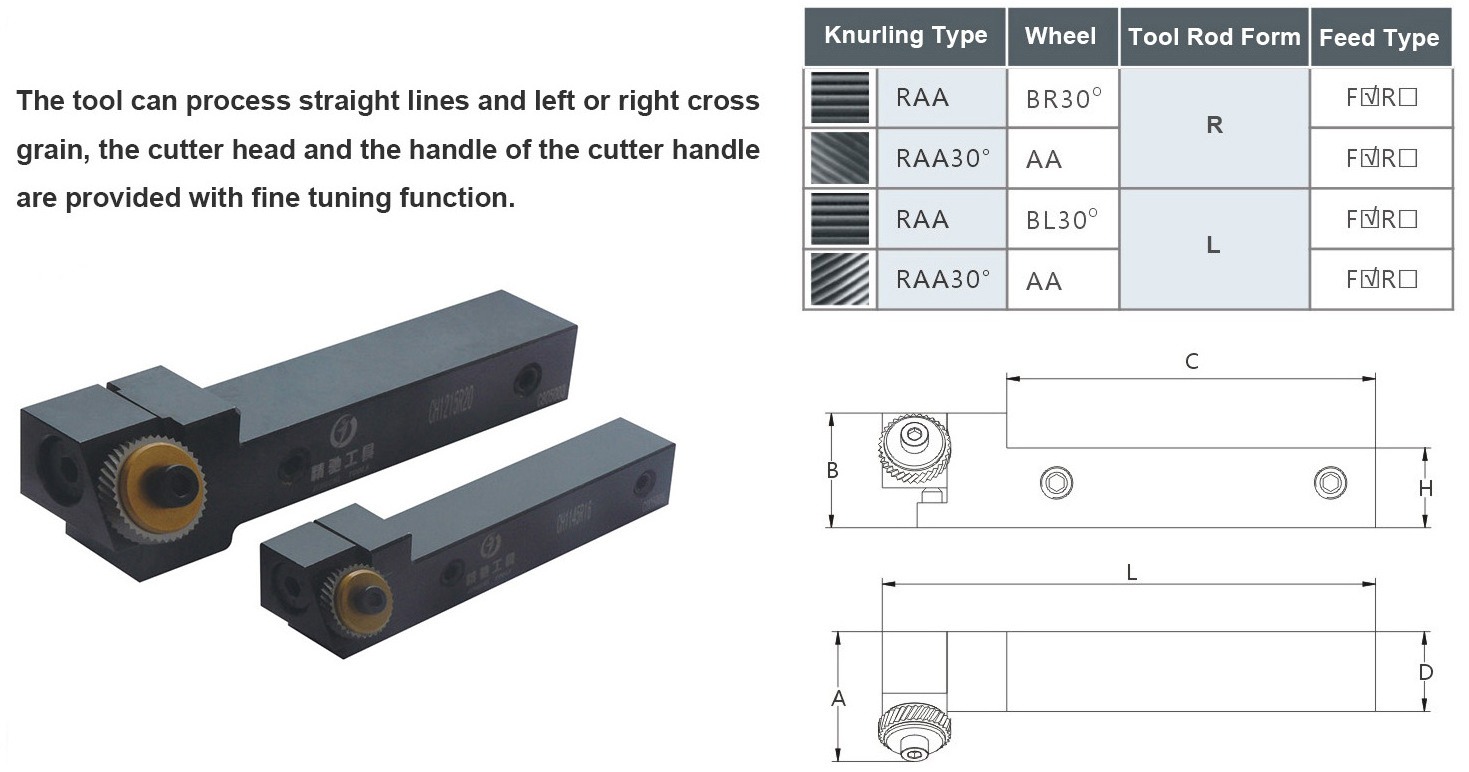

Factory single wheel cutting knurling tools supplier

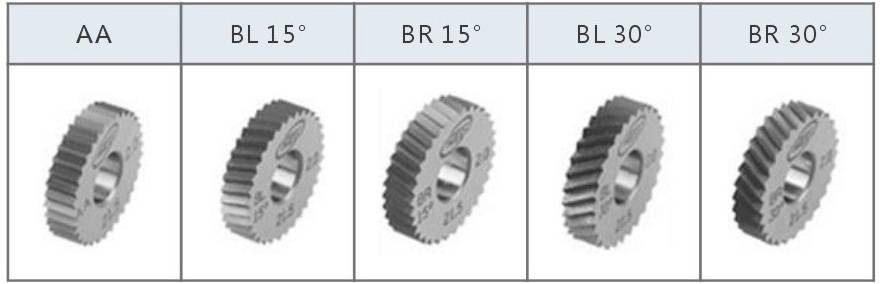

KC-CH Cut knurling tool

Knurling Features: Turning outside diameter knurling tool can adjust the cutting angle, can protect the accuracy of machine tools, low rigidity for small machine tools. Suitable machine type:CNC lathe, automatic lathe. Multi spindle lathe, Swiss type automatic lathe, turn milling machine tool.

Suitable machine type: CNC lathe, automatic lathe, multi spindle lathe, Swiss automatic lathe, turning milling machine.

Single wheel cut knurling tool

Product data

|

Model |

Direction |

Processing Range |

Wheel Size |

Tool Shank Size |

Spare Part |

|||||

|

A |

B |

C |

D |

H |

L |

|||||

|

CH1145R14 |

R+L

|

Φ3-50 |

Φ14.5×3×5 |

26 |

23 |

74 |

16 |

14 |

99 |

EAT14.53

|

|

CH1145R16 |

16 |

|||||||||

|

CH1215R20 |

Φ5-250 |

Φ21.5×5×8 |

39 |

36 |

114 |

25 |

20 |

149 |

EAT21.55 |

|

|

CH1215R25 |

25 |

|||||||||

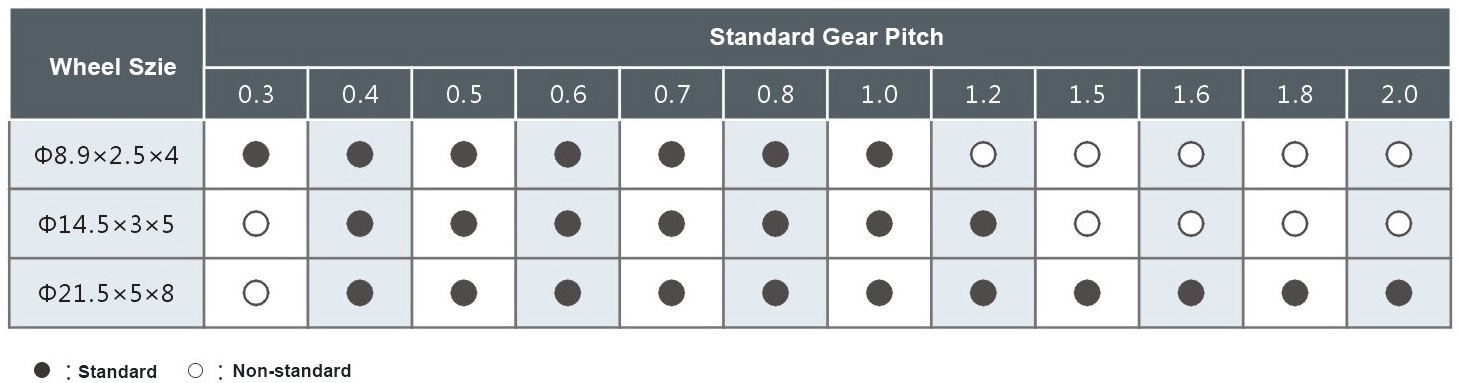

Wheel size

Cut knurling tools usage

1. Clamp the tool into the tool seat, adjust the center height of the tool to ensure the center position of the workpiece.

2. Press the Knurling wheel close to the outer diameter of the workpiece, adjust the two wheels, the whole width of the axis, fully attached to the workpiece.

3. When knurling starts, fast to the distance between the teeth of the 1/2 and the width of the wheel is about 1/3.

4. When the shape is finished, the Z axial feed is started.

5. If the tooth type is wrong, it can be adjusted by adjusting the tool seat axial direction.

6. Use larger cutting fluid to remove the scrap iron.