- Product Details

- {{item.text}}

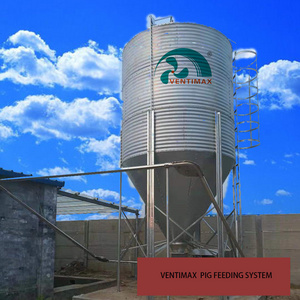

Quick Details

-

Weight:

-

680 KG

-

Name:

-

Chicken house feed Silo

-

Operation:

-

Automatic feeding

-

Advantage:

-

With Visual for inspecting the feed level

-

Different capacity:

-

Available

-

Use for:

-

Chiken Feeder

-

construction:

-

assembly

-

CE:

-

ISO

Quick Details

-

Applicable Industries:

-

Animal feeder, Poultry farm

-

Core Components:

-

driver motor

-

Place of Origin:

-

China

-

Weight:

-

680 KG

-

Name:

-

Chicken house feed Silo

-

Operation:

-

Automatic feeding

-

Advantage:

-

With Visual for inspecting the feed level

-

Different capacity:

-

Available

-

Use for:

-

Chiken Feeder

-

construction:

-

assembly

-

CE:

-

ISO

Function

1. Main feeding line system consists of automatic driving device, a silo, a conveying pipe, an auger and a

feed sensor.

2. The main feeding line system is mainly used to convey the feed in the silo into the hopper of the feeding line and automatically control the conveying opening/closing of the motor by the material level sensor to achieve the aim of automatic feeding.

Performance parameters of main feeding line system

Feature

1, High-quality special driving reduction motor

Power: 0.75kw, voltage: 380V, frequency: 50HZ, three-phase AC current

2, Feeding system

Diameter of conveying pipe: φ75*3.6mm, material: PVC

Helical spring auger from South Africa, Feeding ability: 1,400kg/h, maximum conveying length: 60m

Radius of bending pipe: R1500 (inclination angle: 30 degrees)

3, Material level sensor from Israel: time delay range 0 to 2 hours

Silo capacity:

|

Model |

Volume |

Height (no foundation) |

Diameter |

|

MRS-4.5(1802) |

6.2m3 |

4.9m |

1.833m |

|

MRS-8(2701) |

11.2 m3 |

4.5m |

2.75m |

|

MRS-11.5(2702) |

16.4m3 |

5.68m |

2.75m |

|

MRS-15(2703) |

21.6m3 |

6.8m |

2.75m |

|

MRS-22.5(3602) |

32m3 |

6.9m |

3.667m |

|

MRS-30(3603) |

42m3 |

7.9m |

3.667m |

|

Material description: silo roof plate and silo wall plate 2 layer-galvanized sheets with the thickness of 1.2mm; second layer of silo wall plate-galvanized sheet with the thickness of 1.5mm;

|

|||

Complete chicken house feeding equipment including main feeding line, feeding line (male & female for breeder), drinking line, ventilation system, inviroment controller system

Relevant Spare parts of chicken house

Relevant Feeding Equipment

Our Connect

Our shows