- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HENGYU

-

Product name:

-

Bag Dump Station

-

Application:

-

Bulk Material

-

Speed:

-

2900r/mim

-

Configure:

-

dust collector

-

Operation mode:

-

Manual

-

Machine material:

-

Stainless Steel

-

Power:

-

2*0.18KW

-

Static Load:

-

1500N

-

Layer:

-

1Layer

-

Keyword:

-

Dumping station

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

230

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HENGYU

-

Product name:

-

Bag Dump Station

-

Application:

-

Bulk Material

-

Speed:

-

2900r/mim

-

Configure:

-

dust collector

-

Operation mode:

-

Manual

-

Machine material:

-

Stainless Steel

-

Power:

-

2*0.18KW

-

Static Load:

-

1500N

-

Layer:

-

1Layer

-

Keyword:

-

Dumping station

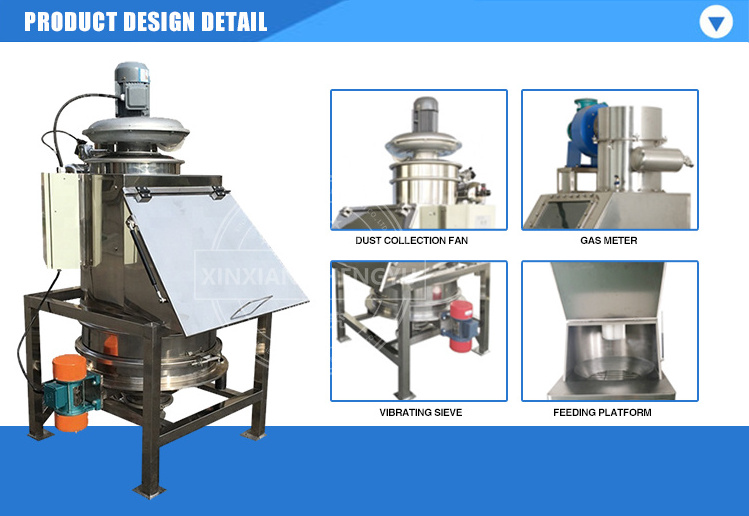

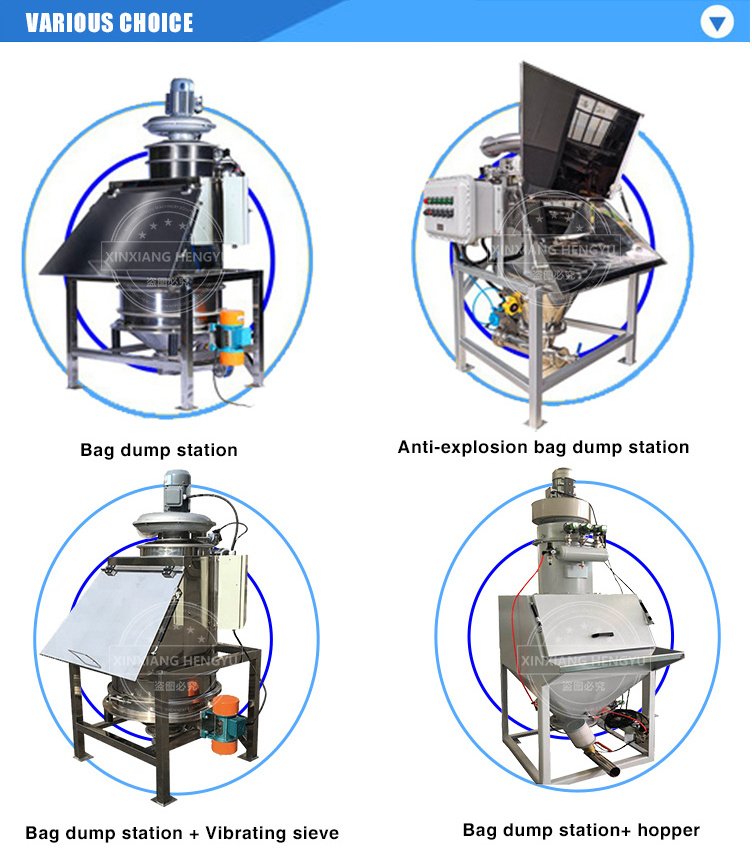

Dust-free Feeding Flour Screen Bulk Powder Granule Material Unload Bags Dumping/Dump Station with Feeder Bag Vibro Sifter

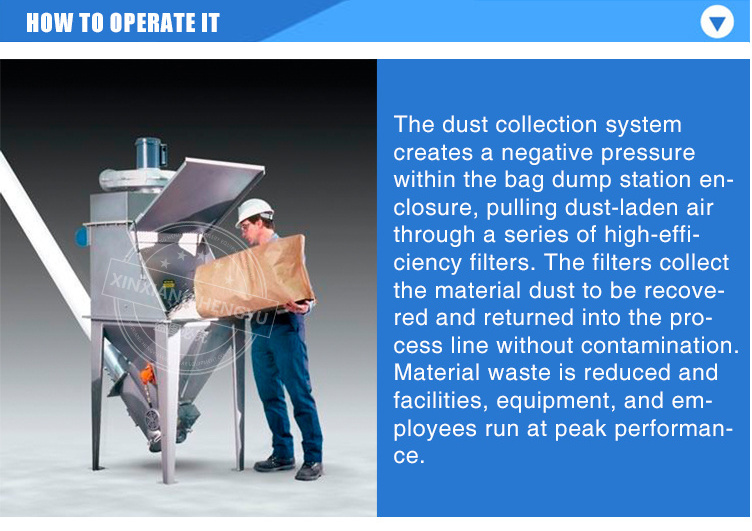

B ag dump station (also known as manual dumping stations) collect dust generated when dumping powder and bulk solids from bags, boxes, drums, and other containers, and return the material to the hopper. The system reduces material waste and eliminates the need to clean a remote dust collection site, while protecting workers and preventing plant contamination.

| Model | Layer | Speed(r.p.m) | Power(KW) | Static Load | Material |

|

800 |

1 | 1460 | 2*0.18 | 1500N | Stainless Steel |

| 1000 | 1 | 1460 | 2*0.25 | 1500N | Stainless Steel |

Bag Dump Station Ideally suited for fine powders, granular or pelletized materials.