- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2000*1300*2000mm

-

Weight:

-

400 KG

-

Capping speed:

-

30-40bottles/min

-

Function:

-

Screwing Pressing Caps

-

Cap diameter:

-

10- 100 mm

-

Capping type:

-

Screw Capping Locking

-

Keywords:

-

Autoamtic Capping Machine

-

Suitable for:

-

Food Beverage Medical Chemical Industry

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Usage:

-

Spray Pump Capping Machines

-

Bottle type:

-

PET Plastic Glass Bottle

-

Product name:

-

Screw Capping Machine

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YIMU

-

Dimension(L*W*H):

-

2000*1300*2000mm

-

Weight:

-

400 KG

-

Capping speed:

-

30-40bottles/min

-

Function:

-

Screwing Pressing Caps

-

Cap diameter:

-

10- 100 mm

-

Capping type:

-

Screw Capping Locking

-

Keywords:

-

Autoamtic Capping Machine

-

Suitable for:

-

Food Beverage Medical Chemical Industry

-

After-sales Service Provided:

-

Video Technical Support Online Support

-

Usage:

-

Spray Pump Capping Machines

-

Bottle type:

-

PET Plastic Glass Bottle

-

Product name:

-

Screw Capping Machine

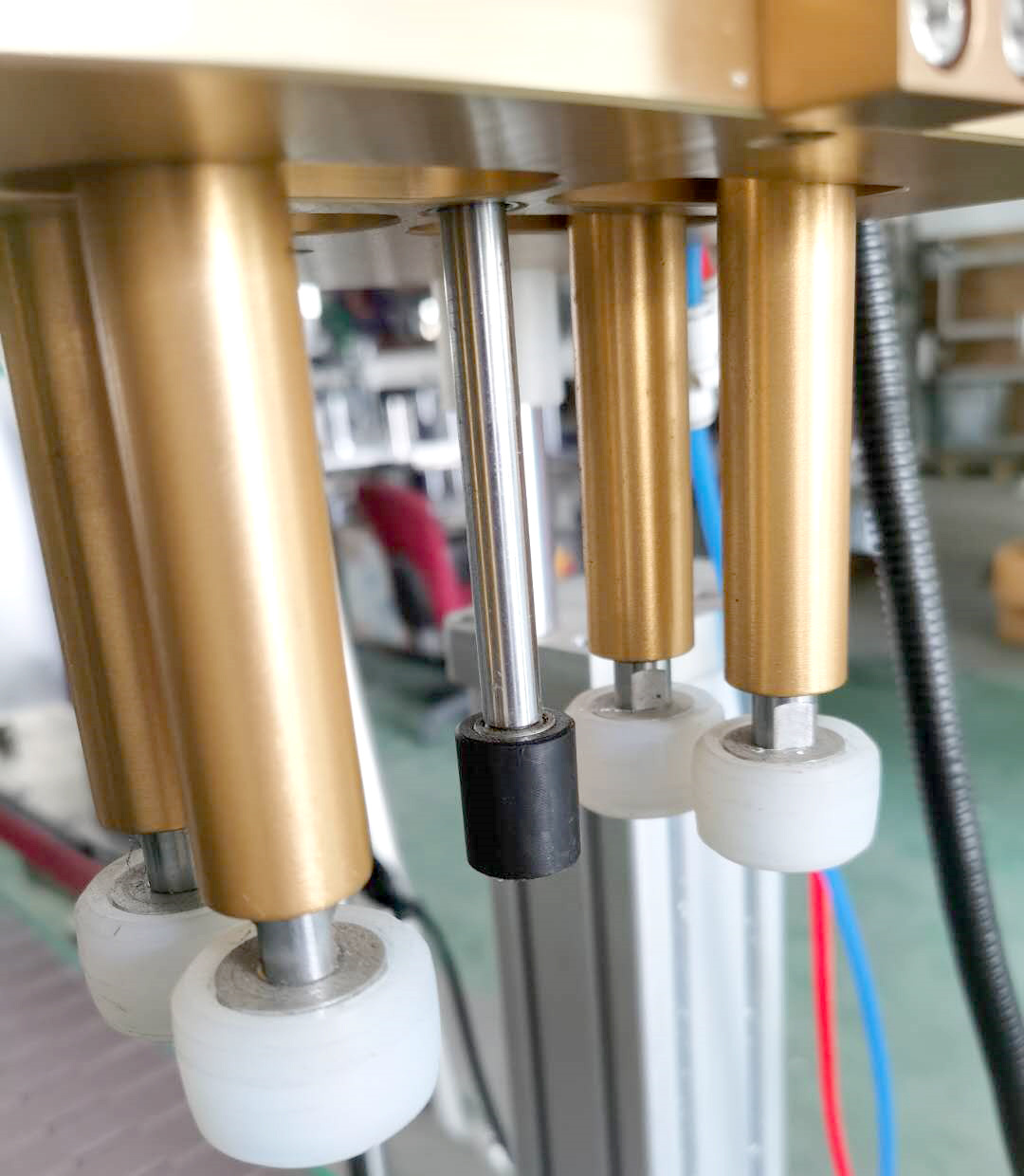

* High efficiency: It utilizes automation technology to perform cap tightening operations at high speed and continuously, thereby improving production efficiency.

* Precision and reliability: By precisely controlling the force and speed of the rotating wheels, it ensures that the caps are securely tightened, preventing looseness or leakage.

* Flexibility and adaptability: It can be adjusted and customized to accommodate different product sizes and shapes, suitable for various types of bottle necks and cap varieties.

* Integration with automation: It can be integrated with other automation equipment such as conveyors and inspection devices to form a complete production line for automated production.

* Precision and reliability: By precisely controlling the force and speed of the rotating wheels, it ensures that the caps are securely tightened, preventing looseness or leakage.

* Flexibility and adaptability: It can be adjusted and customized to accommodate different product sizes and shapes, suitable for various types of bottle necks and cap varieties.

* Integration with automation: It can be integrated with other automation equipment such as conveyors and inspection devices to form a complete production line for automated production.

|

Model

|

CM140

|

|

Applied bottle height

|

50-400mm

|

|

Applied bottle width (diameter)

|

50-200mm

|

|

Applied cap diameter

|

20-100mm

|

|

Success rate of capping

|

>99.99%

|

|

Speed control

|

Frequency conversion adjusting speed

|

|

Cap feeding device

|

Cap elevator or vibrating disk

|

|

Power supply(In China)

|

1500W, 110V/220V, 50/60Hz, 1 phase

|

|

Weight

|

400 KG

|

|

Machine size

|

L2504 * W642 * H1500 mm

|

Hot Searches