- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Onsite Condition

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

1 T

-

Power (kW):

-

320

-

Product Name:

-

Heat treatment furnace

-

Energy medium:

-

ELECTRICAL

-

PLC control:

-

Siemens S7-200 PLC

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

bogie protection system:

-

limit switch at both ends

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

electrical components:

-

Schneider, CHINT or other quality components

-

Color:

-

Support Customzied

-

Weight:

-

2T - 30T

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

WONDERY

-

Voltage:

-

Onsite Condition

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

1 T

-

Power (kW):

-

320

-

Product Name:

-

Heat treatment furnace

-

Energy medium:

-

ELECTRICAL

-

PLC control:

-

Siemens S7-200 PLC

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

bogie protection system:

-

limit switch at both ends

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

electrical components:

-

Schneider, CHINT or other quality components

-

Color:

-

Support Customzied

-

Weight:

-

2T - 30T

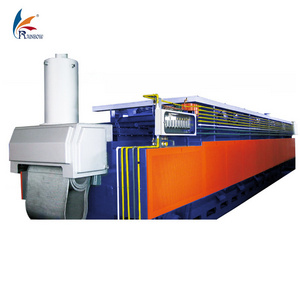

New type practical Continuous Heat Furnace Heat treatment furnace

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Condition

|

New

|

|

Type

|

Electric Bogie Hearth Furnace

|

|

Usage

|

Heat Treatment Furnace

|

|

Brand Name

|

WONDERY

|

|

Voltage

|

Onsite Condition

|

|

Dimension(L*W*H)

|

based on furnace size

|

|

Certification

|

CE CERTIFICATE

|

|

Weight (T)

|

1T

|

|

Power (kW)

|

320

|

|

Warranty

|

1 year

|

|

Applicable Industries

|

Manufacturing Plant

|

|

Product Name

|

Heat treatment furnace

|

|

Energy medium

|

ELECTRICAL

|

|

PLC control

|

Siemens S7-200 PLC

|

|

refractory lining

|

silicate aluminum fiber precompressed blocks

|

|

bogie driving mechanism

|

reducing gear and motor or manual system

|

|

bogie protection system

|

limit switch at both ends

|

|

furnace door lifting mechanism

|

electrical hoist or manual system

|

|

electrical components

|

Schneider, CHINT or other quality components

|

|

Color

|

Support Customzied

|

|

Weight

|

2T - 30T

|

Product Application

All Fiber Type Electric Heat Treatment Furnace With PLC Control is state standard energy saving cyclic furnace. It is a fiber

structure saving 60% power consumption. It is among the first manufacturers to employ compound high aluminum porcelain nail group,trolley anti-explosion sealing bricks, automatic sealing trolley and furnace door, and integrated rail. This series furnace is applicable to the quenching, annealing and aging treatment of high chrome parts, high manganese cast parts, cast iron, rolls,steel balls, 45# steel parts and others.

Main Features

1) All Fiber Type Electric Heat Treatment Furnace With PLC Control has a shell of welded steel plates and sectional steel. The

structure is of thick material.

2) The hearth wall lining is an all-fiber structure, saving about 60% of power consumption compared with the traditional brick

hearth.

3) Heating components: high temperature resistance alloy wires and strips.

4) Low noise, energy-friendliness, and stable performance.

5) Advanced CAD design.

6) Years of experiences in heat treatment process.

Heat treatment furnace

All Fiber Type Electric Heat Treatment Furnace With PLC Control is state standard energy saving cyclic furnace. It is a fiber

structure saving 60% power consumption. It is among the first manufacturers to employ compound high aluminum porcelain nail group,trolley anti-explosion sealing bricks, automatic sealing trolley and furnace door, and integrated rail. This series furnace is applicable to the quenching, annealing and aging treatment of high chrome parts, high manganese cast parts, cast iron, rolls,steel balls, 45# steel parts and others.

Main Features

1) All Fiber Type Electric Heat Treatment Furnace With PLC Control has a shell of welded steel plates and sectional steel. The

structure is of thick material.

2) The hearth wall lining is an all-fiber structure, saving about 60% of power consumption compared with the traditional brick

hearth.

3) Heating components: high temperature resistance alloy wires and strips.

4) Low noise, energy-friendliness, and stable performance.

5) Advanced CAD design.

6) Years of experiences in heat treatment process.

Heat treatment furnace

Wuxi Wondery Industry Equipment Co., Ltd.

is a professional supplier of industrial furnaces. Currently the company mainly supplies the industrial furnaces for heat treatment industry, motor industry, fastener industry, die casting industry, gravity casting industry, steel wire manufacturing industry, etc. Our main products are: aluminum melting furnace, copper melting furnace, zinc melting furnace, crucible melting furnace, rotary melting furnace, melting tower, reverberatory melting furnace, ladle preheater, lader baker, ingot molds,heat treatment furnace, pit type carburizing furnace, pit type nitriding furnace, box type resistance furnace, bogie hearth furnace, salt bath furnace, mesh belt furnace, etc. Established in year 2008, the company has gained rich experiences in development and design, quality control, and after-sales service. The company aims to serve every customer with quality products and excellent service. The company provides thoughtful services like technical consultation, installation and test-running, technical training, and maintenance. Our company is also able to design non-standard products as per customers' requests. We have exported our machines and equipment to the following countries and areas: Taiwan (CHINA), Vietnam, Thailand, Pakistan, India, Venezuela, Bolivia, Mexico, Argentina, Columbia, Australia, USA, Kenya, Ethiopia, Qatar, Egypt, etc. We are capable of providing thoughtful solutions for every individual customer based on their specific requirements, making sure that every potential customer is satisfied with our work.

1. What is the power supply of the industrial furnace?

The power supply of industrial furnace is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer or of the customer's voltage directly so that the industrial furnace is ready for use at the end user's site.

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 15-30 days after receipt of down payment.

Hot Searches