- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DYNNOR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

coal gangue

-

Feeding size:

-

Max. 50mm

-

Discharge size:

-

0-5mm range

-

construction material:

-

carbon steel for main machine

-

shaft rotating speed:

-

1440 r/min

-

Capacity:

-

5-15 ton per hour

-

Motor power:

-

30kw

-

disel engine:

-

optional

Quick Details

-

Weight (KG):

-

2300

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DYNNOR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

coal gangue

-

Feeding size:

-

Max. 50mm

-

Discharge size:

-

0-5mm range

-

construction material:

-

carbon steel for main machine

-

shaft rotating speed:

-

1440 r/min

-

Capacity:

-

5-15 ton per hour

-

Motor power:

-

30kw

-

disel engine:

-

optional

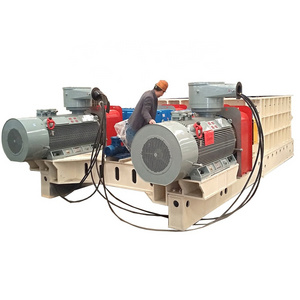

Introduction to compound crusher

The compound crusher is also called vertical compound crusher, which is a new type of high efficiency crushing equipment, which is widely used in the mechanical building sand, stone and various metallurgical slag. It is also an ideal fine crushing equipment for cement raw materials, clinker, technical transformation or new cement production line in cement plant.

The compound crusher is suitable for crushing other medium and hard ores such as iron ore, sandstone, gypsum, blast furnace slag, coal gangue and lump coal, etc. it has the characteristics of large crushing ratio, small energy consumption, stable operation, simple structure, convenient operation and maintenance.

Working principle of compound crusher

Firstly, the material falls vertically into the impeller of high speed rotation from the upper part of the machine. Under the action of high-speed centrifugal force, the material distributed around the impeller in the form of umbrella will produce high-speed impact and crushing. After the material is impacted with each other, the material will be crushed by eddy current formed by eddy current between the impeller and the casing after collision, and then it will be discharged directly from the lower part to form a closed circuit The product size is controlled by screening equipment for several times.

Advantages of compound crusher

Compared with other types of crushers, the compound crusher (composite breaker) has high yield and high efficiency. The crushing ratio is large, and the large crushing ratio can reach the discharging granularity, which can be adjusted arbitrarily, and it is not affected by the wear of the plate hammer and lining plate; without screen strip setting, the materials with high moisture content and large mud content are not easy to block; the elastic adjusting mechanism is adopted to automatically discharge the non-broken materials without damage to the equipment; The bearing is horizontally arranged with long life, and can break materials with high temperature (such as cement clinker); the product is cube, with large stacking density and minimal iron pollution; the rotor body of this machine has unique structure, and the rotor body is almost wear free when crushing materials; the rear cavity is equipped with screw rod or hydraulic opening mechanism, so it can easily replace the vulnerable parts without the main equipment. The noise of the work is lower than 75 dB (DB level), and the dust pollution is less. It is an ideal crushing equipment with high efficiency and environmental protection.

Technical specification of compound crusher

|

Model |

800 |

1000 |

1250 |

1500 |

1750 |

2000 |

|

|

Roll diameter (mm) |

650 |

800 |

1000 |

1250 |

1560 |

1850 |

|

|

Drum height (mm) |

800 |

850 |

850 |

1000 |

1410 |

1620 |

|

|

Main shaft speed (r/min) |

1350 |

970 |

740 |

650 |

600 |

550 |

|

|

Feed size (mm) |

50 |

70 |

100 |

100 |

100 |

120 |

|

|

Output size (mm) |

0-5 |

0-5 |

0-5 |

0-5 |

0-5 |

0-5 |

|

|

Capacity (t/h) |

5-15 |

10-30 |

20-60 |

30-80 |

40-100 |

60-140 |

|

|

Motor |

Model |

Y Series-4 |

Y Series-4 |

Y Series-8 |

Y Series-8 |

Y Series-8 |

Y Series-8 |

|

Power (kw) |

30 |

55 |

75 |

110 |

160 |

200 |

|

|

Rotating speed (r/min) |

1440 |

1440 |

750 |

750 |

750 |

750 |

|

|

Weight (t) |

2.3 |

4.5 |

9.73 |

18.1 |

26.61 |

33.2 |

|

|

Dimensions (mm) |

Length |

2200 |

2700 |

2800 |

3100 |

3350 |

4700 |

|

Width |

860 |

1160 |

1400 |

1900 |

2100 |

2400 |

|

|

Height |

1980 |

2000 |

2730 |

2300 |

2800 |

2600 |

|