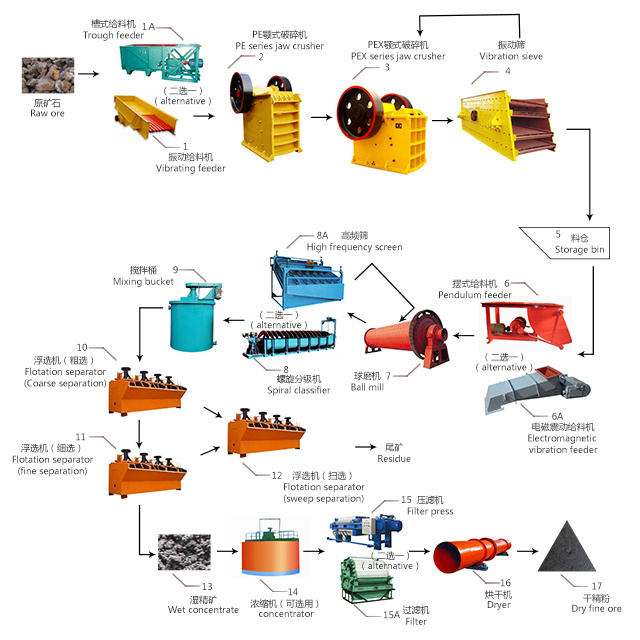

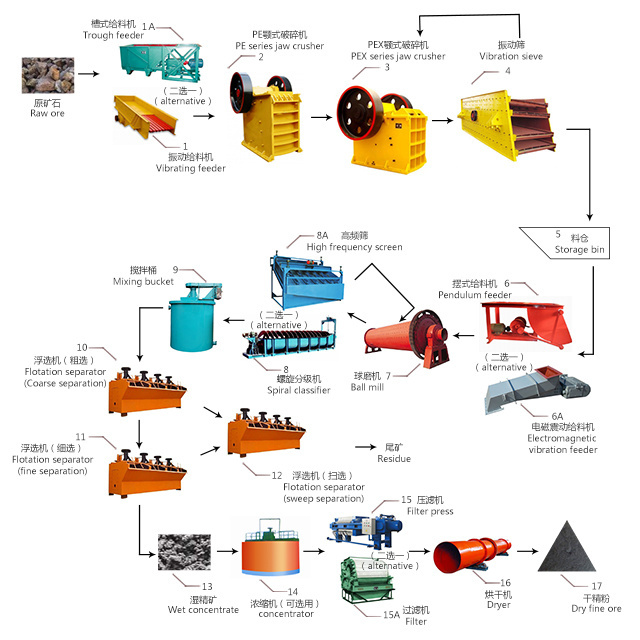

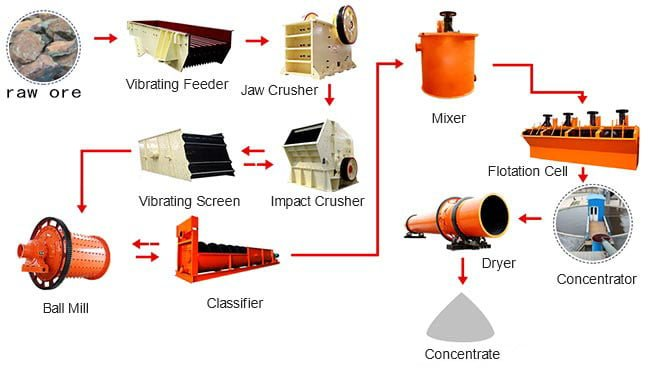

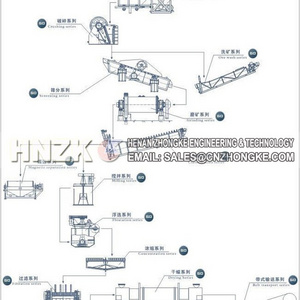

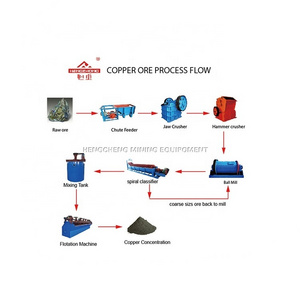

Concentrates and Tailings Processes

Including dehydration of various copper concentrates and tailings products, precipitation concentration, filtration, drying, washing and clarification of fine-grained materials, etc.

Most copper ore beneficiation products contain a lot of water, which is very unfavorable for transportation and smelting processing. Therefore, before smelting, it is necessary to remove the moisture in the beneficiation products.

Most copper ore beneficiation products contain a lot of water, which is very unfavorable for transportation and smelting processing. Therefore, before smelting, it is necessary to remove the moisture in the beneficiation products.

1) Copper concentrate concentration

is the action of gravity or centrifugal force, which makes the solid particles in the beneficiation products precipitate. In order to remove part of the moisture, the concentration is usually carried out in a thickener.

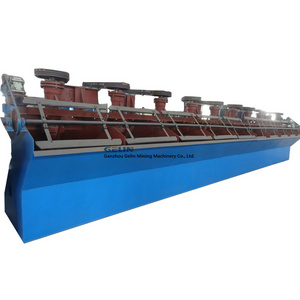

2) Copper concentrate filtration

is the operation of making the ore slurry pass through a water-permeable and impermeable spacer layer of solid particles to achieve solid-liquid separation. Filtration is a further dehydration operation after concentration, usually on a filter.

3) Copper concentrate drying

is the final stage of dehydration. It is an operation to reduce moisture based on the principle of heating and evaporation. But it is only used when the dewatering concentrate still needs to be dried. The drying operation is generally carried out in a dryer, and other drying devices are also used.