- Product Details

- {{item.text}}

Quick Details

-

protecting people:

-

protecting animal

-

protecting crops:

-

disinfection

-

clean environment:

-

corless ulv fogger

-

cold fogger:

-

mist system

-

spray machine:

-

mist sprayer

-

powerful fogger:

-

outdoors and indoors

-

backyard sprayer:

-

garden sprayer

-

knapsack sprayer:

-

mist sprayer

-

disinfection machine:

-

disinfectant fogger

-

pest control fogger:

-

fogger mosquito

Quick Details

-

Time Used:

-

>480 Hours

-

Product:

-

Sticky Type Sticky Type Mosquito-killing Lamp

-

Place of Origin:

-

China

-

protecting people:

-

protecting animal

-

protecting crops:

-

disinfection

-

clean environment:

-

corless ulv fogger

-

cold fogger:

-

mist system

-

spray machine:

-

mist sprayer

-

powerful fogger:

-

outdoors and indoors

-

backyard sprayer:

-

garden sprayer

-

knapsack sprayer:

-

mist sprayer

-

disinfection machine:

-

disinfectant fogger

-

pest control fogger:

-

fogger mosquito

This manual is designed to guide you through the use of BN1010E Sprayer. For safe use of this product read and follow all instructions.

Warning:

Improper use of this product may lead to serious injury , and the factory shall not be responsible .

Read carefully this manual .

If you have any questions, please contact the supplier or contact the company directly. Guarantees period of 12 months for t he sprayer (main parts in chemical tank and motor) .

Application

The BN1010E Sprayer with high efficiency, uniform droplet, long range, supporting high-performance motor, stable performance, reliable and durable, especially suitable for large-scale spray cans, also used in airports, docks, hotels, Hospitals, transport, theaters, communities, places of entertainment and other crowded public places sanitation kill, food processing, pharmaceutical companies, livestock breeding industry disinfection, sanitation and epidemic disinfection.

Safety Precautions

Spraying directly high toxic pesticides, undiluted pesticides, special fluids are prohibited. You should comply with safety instructions the pesticide manufacturers provided when handling pesticides.

Regarding to safety, please do not add combustible, highly volatile special working fluids, such as gasoline, alcohol, benzene and acetone. Do not add strong corrosive liquids, such as caustic soda solution, hydrochloric acid, etc.. To prevent the occurrence of injury or fire and other major security incidents. (Warning: Do not operate the machine with wet hand, keep the body dry, do not keep the body damp or entering water.)

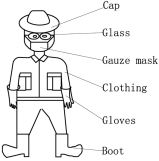

Protective Clothing:

l Wear flanged cap.

l Wear dirt/fog-proof glasses.

l Wear gauze mask.

l Wear long gloves.

l Wear coat guarding against poisons.

l Wear boots.

The sprayer can only be operated by people who are well known with sprayer performance and methods of operation, and have the relevant knowledge of safety. The following persons are prohibited to operate:

1) Children or the elderly

2) Mental illness or sick frail

3) Drinker or take a stimulant, narcotic drugs.

Please pay special attention to the operation and maintenance instructions, understand the correct meaning. Only strictly follow the instructions, then can be ensure the realization of its function.

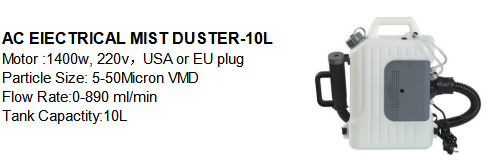

Main technical specifications:

|

Capacity of container |

1 0 L |

Rated voltage |

220v/ 110v, 50hz/60hz |

|

Motor power |

14 00 w |

Spraying distance |

5-7 meter |

|

Rotate speed |

31000r |

Particle dia. |

20 ~50 micron |

|

Net Weight |

4. 90 kgs |

Packing size |

43 *2 2.5 * 48 cm |

Precautions:

1.

Note that the power supply and voltage matches this

sprayer

.

2. Do not pull or wind the power cord forcibly to prevent the wire core from breaking or shorting. Avoid sharp objects to scratch the cable insulation and cause leaking.

3. Be careful not to bend or squeeze the hose, and prevent the hose from piercing by the metal or other sharp objects.

4. Do not turn on and off frequently to avoid damaging switch and motor. if it appears bad smell or abnormal sound, please immediately turn off machine and cut off the power. Unprofessional is forbidden to disassemble machine, do contact with after-sales service or professional repairers when machine break down.

5. In wet season or environment, avoid corrosion inside machine, please make sure start up machine at set intervals.

6. Preserve sprayer in dry environment with low temperature, keep away from children!

7. Keep sprayer dry, must not touch switch with wet hand , avoid danger of electric shock

8. Do not topple or flip machine if it’s filled with liquid, S pecially in transportation.

9. When work finish, wash tank with clean water, detergent is recommended if the sprayer is used for spraying weedkiller.

10. After use, empty and clean the tank and store sprayer at dry and cool place. Prevent it from sunshine.

Using process:

1. Preparation: Put the plug in the socket, open the power switch to check if the motor works well; pour the chemical into the tank after using the filter funnel, tighten screw the tank lid .

2. Start: Turn the power switch on, adjust spray volume to appropriate requirements, then can start spray .

3. Stop: Keep spray nozzle over the chemical tank for 2-3 seconds, MUST TURN OFF the chemical valve first and then power switch after spraying to protect motor from being burnt in case of chemical back flow.

Please be noted that it is the normal phenomenon that the high-speed flow of air causes the

gun and hose to heat up during s praying.

Trouble and treatment:

|

Fault phenomenon |

Reason |

Eliminating methods |

|

Fan not working |

1. Power plug loosed, Poor contactor power wire copper core broken. 2. power switch fault 3. Motor fault 4. Motor carbon brushrust or run out |

1. Check plug, socket or power wire cord 2. Check or replace power switch. 3. Check and repair motor. 4. Check or replace motor carbon brush. |

|

Working but not mist spraying |

1. liquid transfer pipe or valve blocked 2. Liquid transfer pipe or intake pipe folded 3. Liquid transfer pipe fell off 4. Intake pipe is blocked |

1. Clean up or replace 2. Check or correct 3. Reset the liquid transfer pipe 4. Clean up the intake pipe |

|

Intermittent spraying, low volume |

Liquid transfer pipe is blocked/folded/damaged/fell off |

Clean/repair/replace/reset the liquid transfer pipe |

|

Abnormal sound |

1. The intake pipe blocked 2. Motor bearing damaged or carbon brush run out |

1. Clean up the intake pipe 2. Repair or replace the motor |

|

Poor atomization Spray nozzle dripping |

1. Adjusting nut turned too large 2. The intake pipe blocked |

1. Turn down the adjusting nut 2. Clean up the intake pipe |

|

Over-heat of sprayer |

1. Continuous working too long 2. Supply voltage not match 3. The intake pipe blocked 4. The motor seriously worn |

1. Stop working for a while 2. Select correct voltage 3. Clean up the intake pipe 4. Repair or replace the motor |