- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Union

-

Dimension(L*W*H):

-

4200*1800*4000mm

-

Weight:

-

2500 KG

Quick Details

-

Machinery Capacity:

-

3000-5000 boxes/hour

-

Packaging Material:

-

Plastic, Paper

-

Filling Material:

-

Milk, Water, Juice, Yogurt

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Union

-

Dimension(L*W*H):

-

4200*1800*4000mm

-

Weight:

-

2500 KG

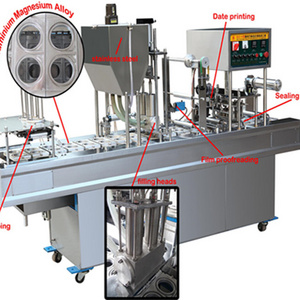

aseptic beverage filling machine

1. Circuit System Control Box: All the components used in this control box are famous brand, which ensure the filling machine runs well and has good performance during the production.

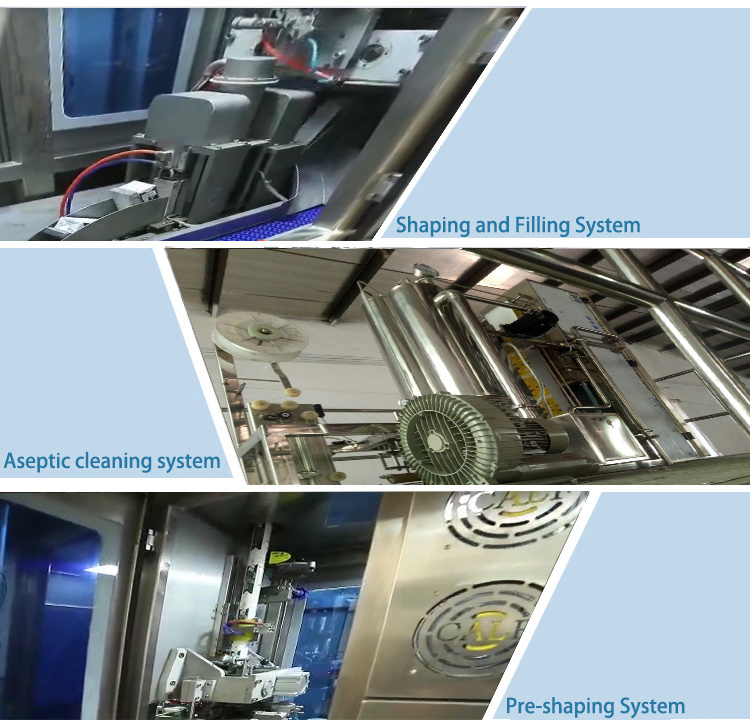

2. Air Filtration Disinfection System: High temperature air heating/filtering system which provides clean air and ozone to the pre-shaping room of aseptic environment.

3. Hydrogen Peroxide & UV Disinfection System: All packing material need to be sterilized through the hydrogen peroxide & UV disinfection system, which ensure the safety of aseptic filling process.

4. Pre-shaping System: The drinks carton will be pre-shaped in this stage, in which the package material after being sterilized will be performed based on an aseptic environment with filtering air and ozone.

5. Shaping and Filling System: The package material will be filled with accurate liquid drinks and formed into aseptic carton(box) , then transported to the conveyor.

6. Touch Screen: The 10 inch touch screen (HMI) is connected with PLC system, it's easy for operation and high accuracy, it has double and multi-language for customers’ choices.