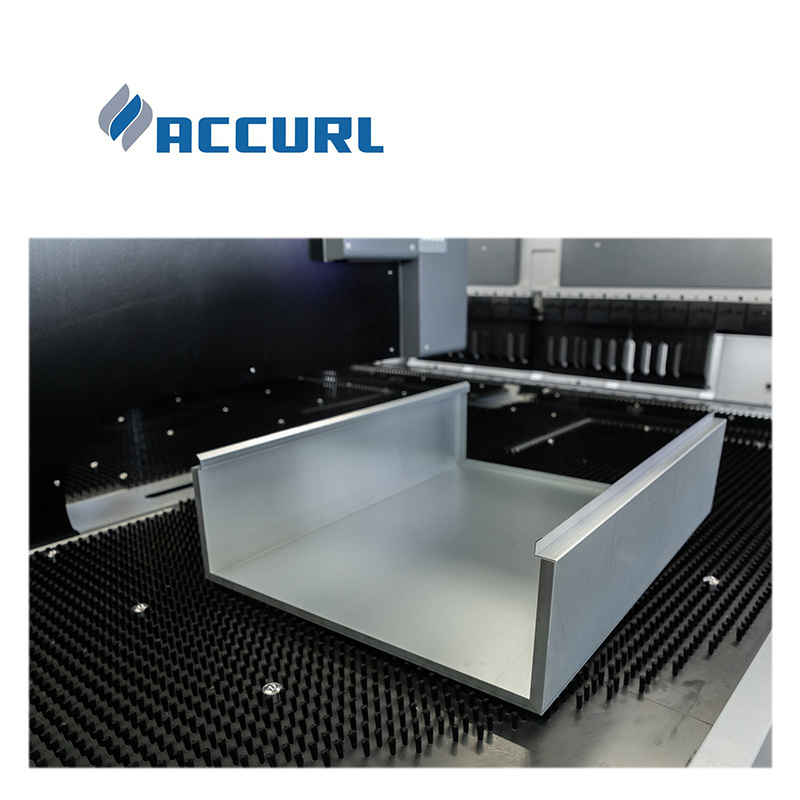

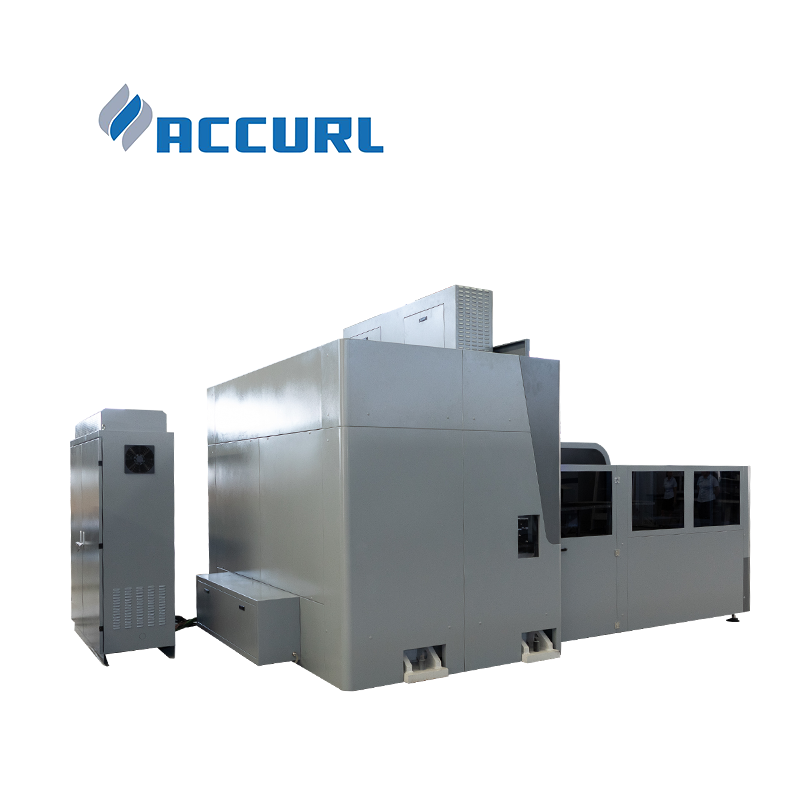

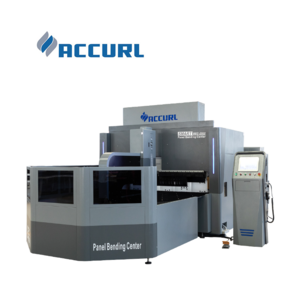

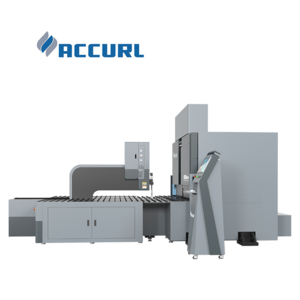

PBESeries panel bender is the new generation automated bending solutions, a benchmark that indicates the upgrading to automation of sheet metal fabricating industry. It can obviously reduce the labor cost and at the same time it can realize 300% higher efficiency comparing to traditional press brake up to 0.3s per bending. Full electro servo transmission plus closed-loop BUS control makes the accuracy far better.

The multilateral bending center does not need to change the mold, the working stroke is short, and the feed is fast.Comprehensive efficiency is 3 to 4 times that of manual bending machine.According to the bending process, it can be automatically folded up and down, so as to realize the bending of arcs, dead edges,and various angles.Highly intelligent operation control system, which can efficiently bend different workpieces.Energy saving and consumption reduction, reducing labor and mold costs.