- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yiguan

-

Model Number:

-

YGH01

-

Name:

-

Brick column processed custom graphite mold for electric furnace

-

W/m.k:

-

110-120

-

Shore Hardness HSD:

-

42

-

Flexural Strength Mpa:

-

38

-

Size/dimension:

-

Customized

-

Granularity (μm):

-

13-15

-

Compressive Strehgth Mpa:

-

65

-

Purity:

-

99wt%

-

Material:

-

High Temperature Resistance Graphite

Quick Details

-

Application:

-

Fountry casting, EDM, glass, battery industry, Industry, foundry etc.

-

Chemical Composition:

-

graphite

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yiguan

-

Model Number:

-

YGH01

-

Name:

-

Brick column processed custom graphite mold for electric furnace

-

W/m.k:

-

110-120

-

Shore Hardness HSD:

-

42

-

Flexural Strength Mpa:

-

38

-

Size/dimension:

-

Customized

-

Granularity (μm):

-

13-15

-

Compressive Strehgth Mpa:

-

65

-

Purity:

-

99wt%

-

Material:

-

High Temperature Resistance Graphite

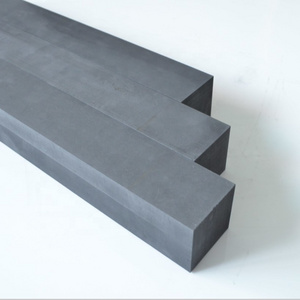

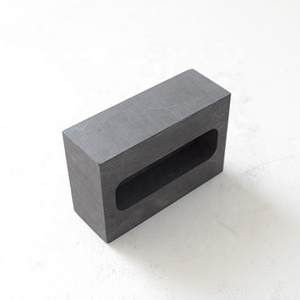

High density brick column processed custom graphite mold for electric research furnace

Brick column processed custom graphite mold are commonly used as heating elements in vacuum systems . When selecting graphite heater vacuum elements, it is important to consider factors such as the required temperature range, power density, dimensions, heating uniformity, and the specific requirements of your vacuum system.

Whether you need a specific shape, size, or design, we can produce high-quality graphite molds tailored to your requirements.

1. High temperature resistance

2. G ood oxidation resistance

3. high mechanical strength

4. Good self-lubricating property

5. Chemical corrosion resistance

6. Homogeneous structure ,low permeability

Technical parameters

|

YG - 4 |

YG - 5 |

YG - 6 |

|

|

Volume Density g/ cm³ |

≥1.7 5 |

≥1.8 5 |

≥1. 90 |

|

Grain Size μm |

13-15 |

13-15 |

8-10 |

|

Ash PPM |

≤500 |

≤500 |

/ |

|

Electric Resistance μΩm |

10-13 |

8-10 |

8-9 |

|

Flexural Strength M p a |

38 |

48 |

55 |

|

Compressive Strength Mpa |

≥65 |

≥85 |

≥9 5 |

|

Shore Hardness |

≥4 2 |

≥ 48 |

≥5 3 |

Industrial ovens graphite heaters are commonly used in applications like vacuum furnaces, vacuum brazing, heat treatment processes, thermal evaporation and deposition, sputtering systems, and analytical instruments such as mass spectrometers and electron microscopes.

As a factory with over 20 years manufacturing experiences, our graphite heater products had accept by our customers.

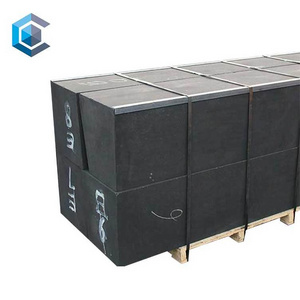

In order to protect the our graphite products, no matter graphite heaters, graphite crucible or other graphite products, we package our graphite products with wooden boxes or canton boxes. For small mold or samples, normally use carton box; For bigger or quantities mold, normally use wooden boxes.

We can provide the packing list inside the box, the contents including type, specification, number, quantity or weight, manufacturer, production date, origin, etc.

As a factory specializing in carbon graphite heater for industrial furnace production, we understand the importance of providing customized solutions to meet the unique needs of our clients.

Our team of skilled professionals is equipped to machine various graphite elements according to your specific drawings.