- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

6 - 10

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Rated Power:

-

25KW

-

Dimension(L*W*H):

-

200*300*200

-

Weight:

-

20000

-

Year:

-

2024

-

Production Name:

-

Steel Coil Slitting production line

-

Type:

-

Automatic

-

Usage:

-

steel or plate

-

Raw material:

-

Galvanized Coil

-

Thickness:

-

0.3-2mm

-

Roller material:

-

Cr12 Steel Quenched

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

Delta

-

Motor brand:

-

Mistubishi

-

Advantage:

-

PLC Control

Quick Details

-

Cutting Width (mm):

-

400 - 1600 mm

-

Material Thickness(mm):

-

0.3 - 2 mm

-

Cutting Speed(m/min):

-

1 - 200 mm

-

No. of Slitting Lines:

-

6 - 10

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Rated Power:

-

25KW

-

Dimension(L*W*H):

-

200*300*200

-

Weight:

-

20000

-

Year:

-

2024

-

Production Name:

-

Steel Coil Slitting production line

-

Type:

-

Automatic

-

Usage:

-

steel or plate

-

Raw material:

-

Galvanized Coil

-

Thickness:

-

0.3-2mm

-

Roller material:

-

Cr12 Steel Quenched

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

Delta

-

Motor brand:

-

Mistubishi

-

Advantage:

-

PLC Control

Products Description

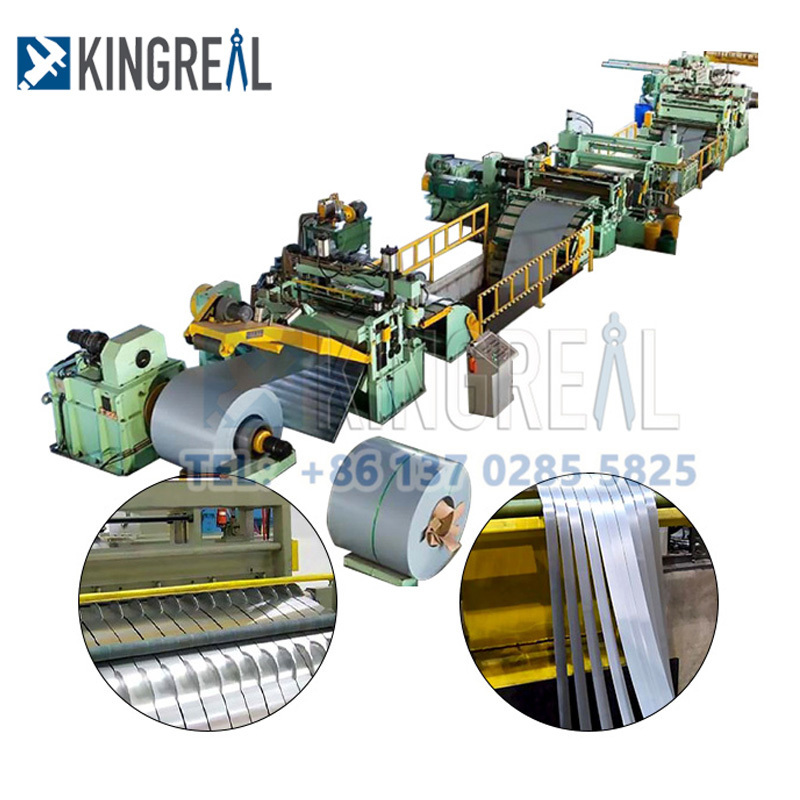

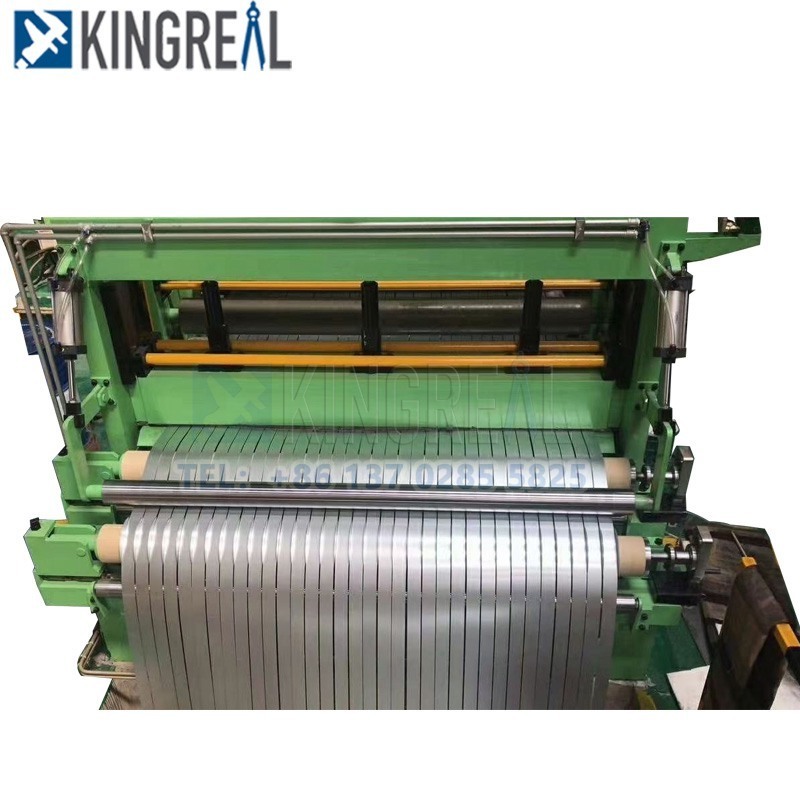

0.3-2.0mm Precision Galvanized Steel coil slitting machine slitter production line

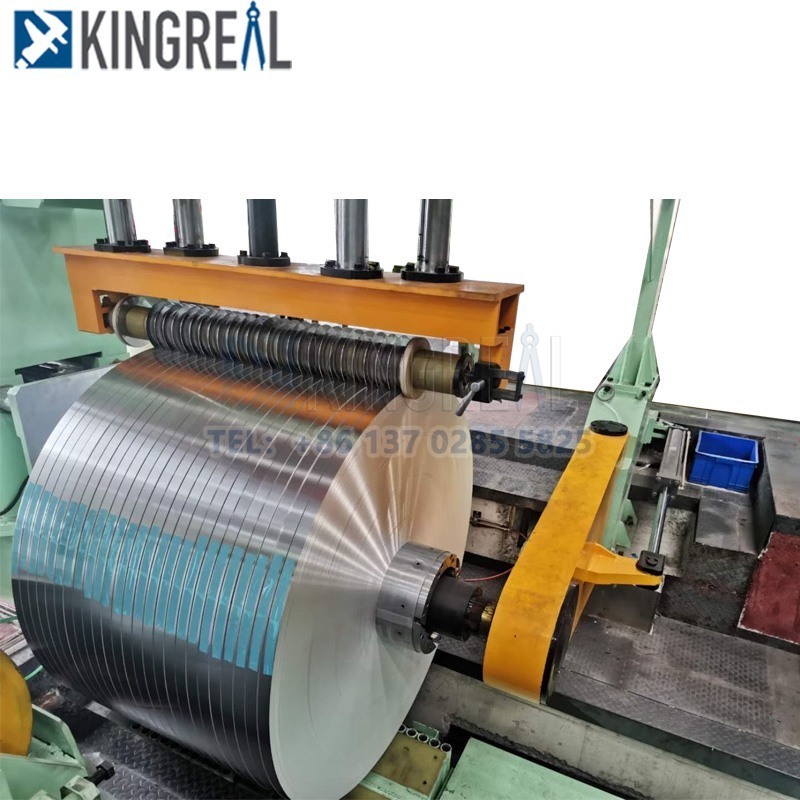

Steel coil slitter processing equipment and slitting machine: mainly used for stainless steel strip/coil, carbon steel strip,

copper strip and other production slitting. By the loading trolley, uncoiling, leveling machine, slitting host, shear, buffer pool, up force station, winding and other processes production.

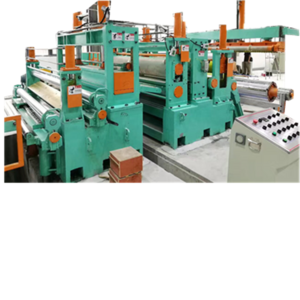

This machine is used for uncoiling, leveling, longitudinal shearing, flattening and winding of stainless steel, galvanized sheet and cold rolled sheet coils, with high automaticity and high production efficiency. The whole line is electrically and pneumatically controlled, with high processing accuracy.

Mechanical Characteristics:

The use of double disc cutters can shorten the time of arranging the knives, which is very suitable for the slitting production line where the quantity of each order is not large and often requires arranging disc knives, improving the economic benefits of the enterprise.

Performance Feature :

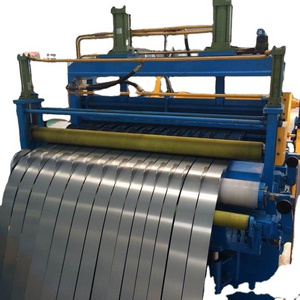

1.The main function is to shear the wider metal coil along the length direction into multiple required width strips .

2.

Prepare billets for rolling, blanking, cold bending, stamping and other processes.

3.

By adjusting the distance between the upper and lower tool shafts, to adapt to different thickness

of the plate.

4. It can be cut into strips of different widths by replacing diaphragms and diaphragms of

blades of different specifications

Technical Specification is follows:

|

Material width

|

600mm, 800 mm, 1200 mm, 1250mm

|

|

|

|

|||

|

Raw Material

|

Stainless Steel, Carbon Steel, Galvanized Steel, Aluminum , Copper, Sliver

|

|

|

|

|||

|

Speed of feed

|

0-180 m/min

|

|

|

|

|||

|

Coil. I.D

|

D480-D520 MM

|

|

|

|

|||

|

Coil. O.D

|

1900 MM

|

|

|

|

|||

|

Strip Weight

|

It is about 5 tons to 30tons

|

|

|

|

|||

|

Power

|

AC 380V

|

|

|

|

|||

Slitting Machine Manufacturing Workshop:

Working Process

Certifications

Our products have passed the international ISO9001 and European CE certification,

and being exported to many European countries.

Why Choose Us

Related products

Hot Searches