- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2800mm*6600mm

-

Year:

-

2022

-

Power (kW):

-

25 kW

-

Weight (KG):

-

25000 KG

-

Raw material:

-

waste plastic ,pp pe ps , medical waste ,MSW

-

Final product:

-

plastic oil , carbon black,syngas

-

Heating Fuel:

-

coal wood oil and gas

-

landing area:

-

400 square meter

-

Certificates:

-

CE, ISO9001,BV

-

Function:

-

pyrolysis of used tyre

-

Production Capacity:

-

1-10 ton

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Core Components:

-

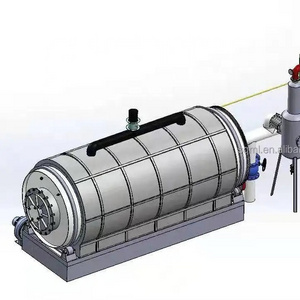

pyrolysis reactor, condenser

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2800mm*6600mm

-

Year:

-

2022

-

Power (kW):

-

25 kW

-

Weight (KG):

-

25000 KG

-

Raw material:

-

waste plastic ,pp pe ps , medical waste ,MSW

-

Final product:

-

plastic oil , carbon black,syngas

-

Heating Fuel:

-

coal wood oil and gas

-

landing area:

-

400 square meter

-

Certificates:

-

CE, ISO9001,BV

-

Function:

-

pyrolysis of used tyre

-

Production Capacity:

-

1-10 ton

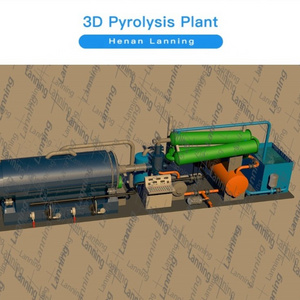

Product details

Tire pyrolysis provides an effective solution for recycling and reusing used tires that would otherwise end up in landfills or be subjected to environmentally harmful disposal methods. Pyrolysis of tires allows for the recovery of valuable resources from the waste material. The process produces pyrolysis oil, carbon black, and combustible gas, which can be utilized as energy sources or raw materials in various industries.

|

Input raw material

|

Waste car tyres , bicycle tires, OTR tyres, rubber etc.

|

|

|

|

Output product

|

Percentage

|

Application

|

|

|

Fuel oil

|

45%

|

Used as industrial fuel for cement plant, steel plant, metallurgical plant, glass plant, power plant etc.

|

|

|

Carbon black

|

30%

|

Used as raw materials for rubber and plastic industries after further processing. Or used as heating fuel.

|

|

|

Steel wire

|

15%

|

Sold to scrap metal dealers.

|

|

|

Syngas

|

10%

|

Routed to gas burners of heating system as fuel supply.

|

|

Product Paramenters

|

Model

|

HY-05

|

HY-08

|

HY-10

|

HY-15

|

HY-30

|

||||

|

Capacity

|

5 t/d

|

8 t/d

|

10 t/d

|

15 t/d

|

30-50 t/d

|

||||

|

Working Type

|

Batch

|

Batch

|

Batch

|

Batch

|

Continuous

|

||||

|

Reactor size(m)

|

D2.2*L5.5

|

D2.6*L6.6

|

D2.8*L6.6

|

D2.8*L8.1

|

D1.2*L24

|

||||

|

Reactor material

|

Q245R

|

Q245R

|

Q245R

|

Q245R

|

310S stainless steel

|

||||

|

Power

|

29.4KW

|

29.4KW

|

32KW

|

34KW

|

100KW

|

||||

|

Heating Fuel

|

Pyrolysis oil /coal/ wood/natural gas ( if you use fuel oil gas heating material , then the oil burners are required)

|

|

|

|

|

||||

|

Burners

|

3*300,000 kcal

|

3*300,000 kcal

|

3*300,000 kcal

|

4*300,000 kcal

|

12*30000kcal

|

||||

|

Landing Area

|

200m2

|

250m2

|

300m2

|

350m2

|

700m2

|

||||

|

Number of Containers

|

1*40FR+1*40HQ

|

1*40FR+2*40HQ

|

1*40FR+2*40HQ

|

1*40FR+2*40HQ

|

bulk cargo

|

||||

|

Cooling Mode

|

Circle Water

|

Noise (dB)

|

≤60

|

Working pressure

|

Normal

|

||||

Models of Huayin Pyrolysis Plant

|

Model A series

|

Model C series

|

Model F series

|

Model M series

|

Model S series

|

|

5/10/15 tons

|

5/10/15 tons

|

750/4000kg

|

10kg

|

30/50 tons

|

|

Basic choice to start

|

Advanced choice

|

Installation-FREE

|

Mini scale model

|

Continuous type

|

|

Medium emission control

|

High emission control

|

Low shipping cost

|

Fully operational

|

High-end choice

|

|

Onsite installation

|

Quick installation

|

Modular design

|

Installation-FREE

|

Onsite installation

|

Product Features

Safety.

We treat safety as the first important thing in production.

1. Two devices to avoid backfire in production: oil-water separator and anti-back fire device.

2. Vacuum device makes the reactor work under ordinary pressure or negative pressure.

3. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

Environmental protection

1. The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by a powerful ceramic packing dust

removal device, then can be released into the air through the chimney.

3. Carbon black will be discharged out in sealed condition to avoid pollution.

Energy saving

1. The flame path is designed as a spiral so that the quantity of heat can be fully used.

2. The syngas is recycled to heating furnace for burning, thus saving your heating fuel.

3. The insulation cover is formed by 3 layers: steel plate, rock wool, and refractory cement. Excellent thermal insulation effect helps save fuel.

2. Vacuum device makes the reactor work under ordinary pressure or negative pressure.

3. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

Environmental protection

1. The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by a powerful ceramic packing dust

removal device, then can be released into the air through the chimney.

3. Carbon black will be discharged out in sealed condition to avoid pollution.

Energy saving

1. The flame path is designed as a spiral so that the quantity of heat can be fully used.

2. The syngas is recycled to heating furnace for burning, thus saving your heating fuel.

3. The insulation cover is formed by 3 layers: steel plate, rock wool, and refractory cement. Excellent thermal insulation effect helps save fuel.

Installation cases

Packing and shipping

Delivery time : 15 working days after received the deposit.

Hot Searches