- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

STA

-

Dimension(L*W*H):

-

customized

-

Weight:

-

10000 KG

-

Working Temperature Range:

-

0 - 950 ℃

-

Material:

-

silicate aluminum fiber

-

Usage:

-

Heat Treatment Furnace

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

bogie protection system:

-

limit switch at both ends

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

Heating elements:

-

0Cr25AL5

-

electrical components:

-

Schneider, CHINT or other quality components

Quick Details

-

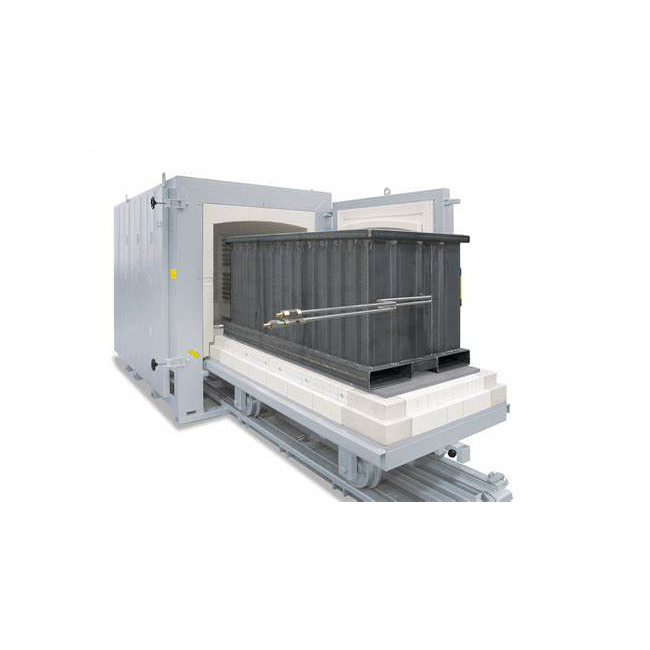

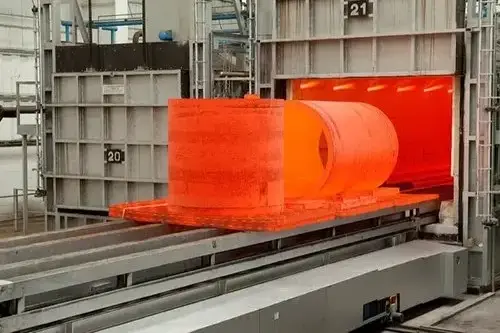

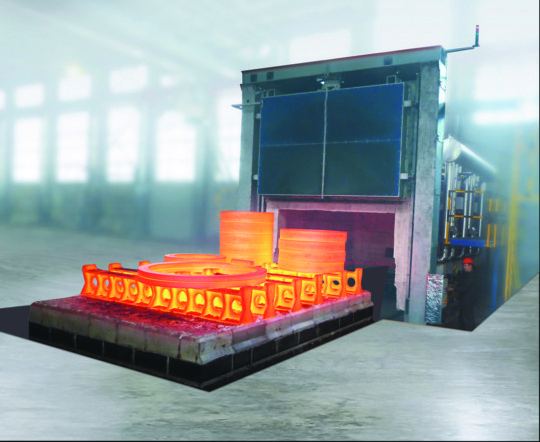

Type:

-

Gas Bogie Hearth Furnace

-

Power Source:

-

Gasoline

-

Voltage:

-

customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

STA

-

Dimension(L*W*H):

-

customized

-

Weight:

-

10000 KG

-

Working Temperature Range:

-

0 - 950 ℃

-

Material:

-

silicate aluminum fiber

-

Usage:

-

Heat Treatment Furnace

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

bogie protection system:

-

limit switch at both ends

-

furnace door lifting mechanism:

-

electrical hoist or manual system

-

Heating elements:

-

0Cr25AL5

-

electrical components:

-

Schneider, CHINT or other quality components

Product Description

Product Application

Trolley Type Resistance Furnace is state standard energy saving cyclic furnace. It is a fiber structure saving 60% power consumption. It is among the first manufacturers to employ compound high aluminum porcelain nail group, trolley anti-explosion sealing bricks, automatic sealing trolley and furnace door, and integrated rail. This series furnace is applicable to the quenching, annealing and aging treatment of high chrome parts, high manganese cast parts, cast iron, rolls, steel balls,

45# steel parts and others.

45# steel parts and others.

Packing & Delivery

|

Packaging

|

|

|

|

Size

|

2200 (L) * 1500 (W) * 1500 (H)

|

|

|

Weight

|

1000KG |

|

|

Packaging Details

|

1.The furnace body was wrapped with enrivonmental plastic stretch film, then fixed well on the fumigation-free pallet

2.Tailored polywood case, coupled perfectly with the pallet 3.Filled with polyfoam between the furnace body and the case in all sides 4.Easy-to-identify double-sided outer box print logos and shippment marks |

|

|

|

|

|

|

|

|

|

Hot Searches