Automatic uncoiler for kichen sink and wash basin production line is a flexible metal forming plant that uses a number of different sheet metal fabrication equipment to form a highly efficient manufacturing line.

This series of production lines are used to process thin coils of different specifications, suitable for processing cold-rolled sheets, galvanized sheets, color-coated sheets, and stainless steel sheets. After uncoiling, leveling, and shearing, it becomes a flat sheet of the required length.

This metal sink/wash basin production line can greatly help you increase your manufacturing output and efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

JY

-

Year:

-

2020

-

Voltage:

-

optional

-

Dimension(L*W*H):

-

1000x900x2900mm

-

Weight (T):

-

5000 T

-

Model Number:

-

JY

-

Motor Power (kw):

-

22 kw

-

Style:

-

kitchen sink production line

-

Structure:

-

Four Column Machine

-

Material:

-

Steel Material

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Stamping Metal Product

-

Model:

-

Deep Punching Machine

-

Frame:

-

Integrate High Rigid Steel Frame

-

Item:

-

Hydraulic Forming Press Machine

-

Feature:

-

Hydroforming Press

-

Power souce:

-

Electricity Hydraulic Power

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Ejector Force (kN):

-

55

-

Return Force (kN):

-

5000 kN

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

JY

-

Year:

-

2020

-

Voltage:

-

optional

-

Dimension(L*W*H):

-

1000x900x2900mm

-

Weight (T):

-

5000 T

-

Model Number:

-

JY

-

Motor Power (kw):

-

22 kw

-

Style:

-

kitchen sink production line

-

Structure:

-

Four Column Machine

-

Material:

-

Steel Material

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Stamping Metal Product

-

Model:

-

Deep Punching Machine

-

Frame:

-

Integrate High Rigid Steel Frame

-

Item:

-

Hydraulic Forming Press Machine

-

Feature:

-

Hydroforming Press

-

Power souce:

-

Electricity Hydraulic Power

Contacts: David Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@weldcnc.com

Mob/Whatsapp: +86 133 9411 0095

Product Description

Kitchen sink/wash basin production line machines and equipments Solution Description

A. Cut sheet materials by automatic feeder system and shearing machine.

B. Deep drawing of sink bowl carried out by hydraulic press.

C. Stamping filter of kitchen sinks.

D. Edge trimming effectuated by hydraulic press.

E. Form edges by hydraulic press.

F. Stamp and cut drain holes by press machine.

G. Cut overflow holes at the side of the bowl by press machine.

H. Draw filter parts in water flow holes. There are 3 parts of it.

I. Polish 4 internal faces of the kitchen sink.

J. Polish the upper surface of the kitchen sink.

K. Polish the button of the kitchen sink.

B. Deep drawing of sink bowl carried out by hydraulic press.

C. Stamping filter of kitchen sinks.

D. Edge trimming effectuated by hydraulic press.

E. Form edges by hydraulic press.

F. Stamp and cut drain holes by press machine.

G. Cut overflow holes at the side of the bowl by press machine.

H. Draw filter parts in water flow holes. There are 3 parts of it.

I. Polish 4 internal faces of the kitchen sink.

J. Polish the upper surface of the kitchen sink.

K. Polish the button of the kitchen sink.

Automatic uncoiler for kitchen sink

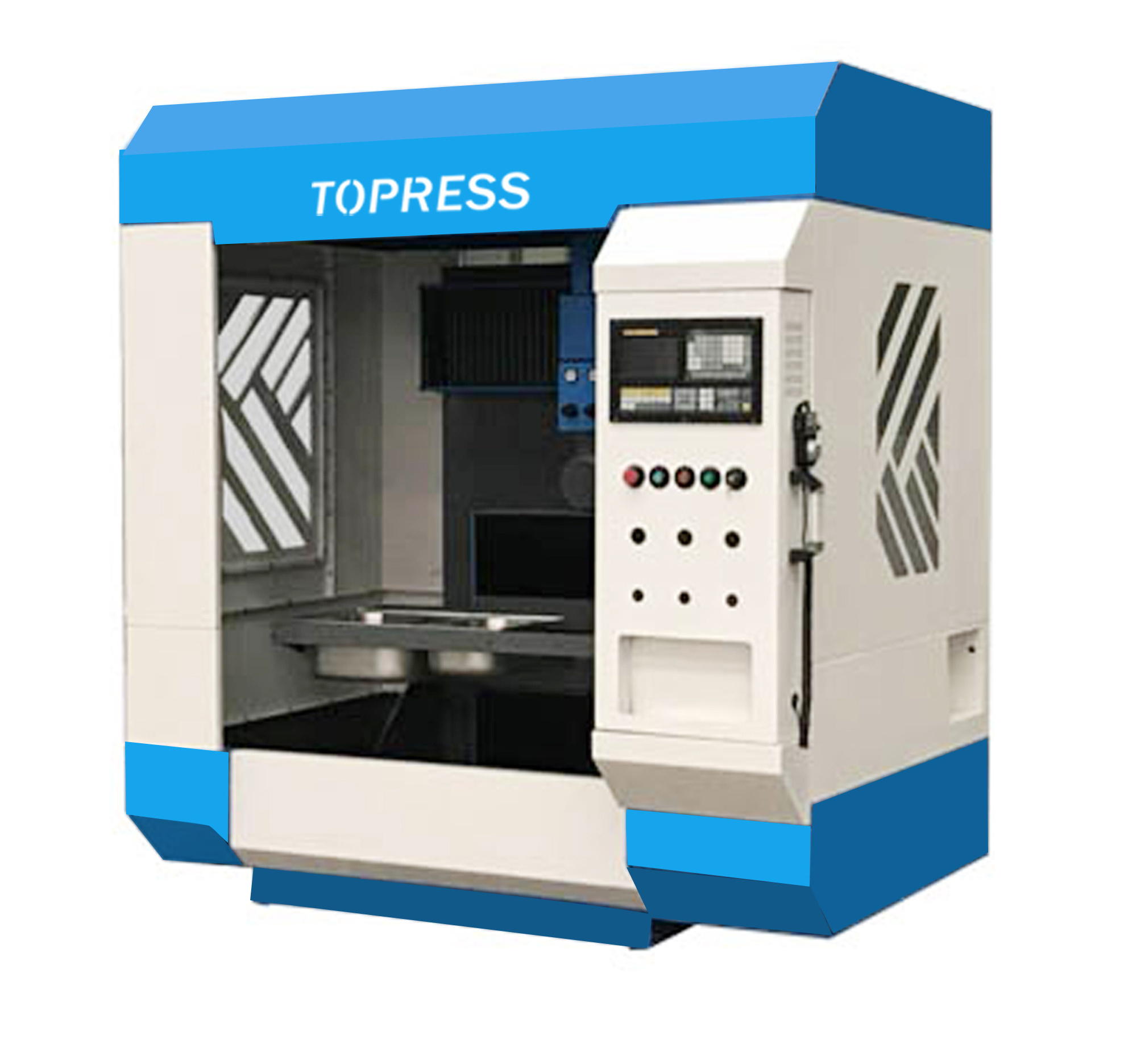

Deep drawing hydraulic press/stretching machine

Gantry type deep drawing hydraulic press/stretching machine

Low maintenance cost, low failure rate, safe and convenient

Fully automated operating system/manual control system, centralized button control

Product details

Want to know this machine more information! Contact us>>

Punching machine

Punching machine for kitchen sink/wash basin production line are mainly used for cutting, stamping, blanking, bending and light

stretching work.

stretching work.

High precision, high efficiency, simple and convenient operation, good performance, favorable price and good service.

CNC Matte or mirror polishing machine

flat side matte or mirror polishing machine

Kitchen sink side matte or mirror polishing machine

Kitchen Sink and wash basin bottom side matte or mirror polishing machine

Kitchen sink outside and inside matte or mirror polishing machine

Through-type stainless steel kitchen sink ultrasonic cleaning line

The whole machine adopts a special chain to transport and clean, and the cleaning efficiency is high, which not only saves electric energy, but also reduces the failure rate.

Combining the high-pressure spray cleaning process to carry out continuous degreasing and cleaning of the water tank, the filter system is practical and effective; the space layout of each part is reasonable and there are maintenance channels, and the appearance is simple and beautiful.

For operational safety and equipment maintenance considerations, the entire cleaning line adds stainless steel baffles where the motors and pipelines work.

Combining the high-pressure spray cleaning process to carry out continuous degreasing and cleaning of the water tank, the filter system is practical and effective; the space layout of each part is reasonable and there are maintenance channels, and the appearance is simple and beautiful.

For operational safety and equipment maintenance considerations, the entire cleaning line adds stainless steel baffles where the motors and pipelines work.

Hanging type stainless steel kitchen sink and wash basin spray cleaning line

The equipment is mainly composed of an ultrasonic dewaxing tank, bubbling rinsing tank, heating system, ultrasonic system,suspension transmission system, electrical control system, etc. An automatic assembly line equipment.

Ultrasonic specializes in the production of ultrasonic cleaning machines, spray cleaning machines, industrial drying equipment, industrial pure water equipment, automatic cleaning and drying lines; non-standardized, providing customers with a one-stop solution for cleaning and drying, with one-year warranty and lifetime maintain.

Ultrasonic specializes in the production of ultrasonic cleaning machines, spray cleaning machines, industrial drying equipment, industrial pure water equipment, automatic cleaning and drying lines; non-standardized, providing customers with a one-stop solution for cleaning and drying, with one-year warranty and lifetime maintain.

Product Paramenters

Deep drawing hydraulic press/stretching machine

Product parameters

|

Type

|

Unit

|

63T

|

100T

|

160T

|

200T

|

315T

|

630T

|

1000T

|

2000T

|

|

Ejecting force

|

KN

|

100

|

200

|

250

|

400

|

630

|

1000

|

1200

|

2000

|

|

Nominal pressure

|

KN

|

630

|

1000

|

1600

|

2000

|

3150

|

6300

|

10000

|

20000

|

|

Slider Stroke

|

mm

|

500

|

500

|

500

|

700

|

800

|

900

|

900

|

1400

|

|

Max.opening height

|

mm

|

700

|

900

|

900

|

1120

|

1250

|

1500

|

1500

|

1600

|

|

Ejecting Stroke

|

mm

|

160

|

200

|

200

|

250

|

300

|

300

|

400

|

450

|

|

Power of motor

|

KW

|

5.5

|

7.5

|

15

|

18.5

|

22

|

45

|

68

|

134

|

|

Max.Working pressure

|

Mpa

|

25

|

26.2

|

26

|

25

|

25

|

26

|

26

|

27

|

|

Table size(F.B.)

|

mm

|

500

|

580

|

800

|

900

|

1200

|

1500

|

1600

|

2000

|

|

Table size(L.R.)

|

mm

|

500

|

710

|

800

|

900

|

1200

|

1500

|

1600

|

2800

|

|

Idle stroke

|

mm/s

|

76

|

100

|

100

|

100

|

>100

|

>100

|

>100

|

>100

|

|

Pressing

|

mm/s

|

10

|

8-15

|

8-15

|

8-15

|

8-15

|

10

|

12

|

10

|

|

Return

|

mm/s

|

60

|

60

|

60

|

70

|

70

|

65

|

80

|

>75

|

|

Total Weight

|

T

|

2.5

|

4

|

7

|

12

|

15

|

38

|

48

|

145

|

Products Recommended

Company Profile

Hot Searches