- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

zle06

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

zhele

-

Product name:

-

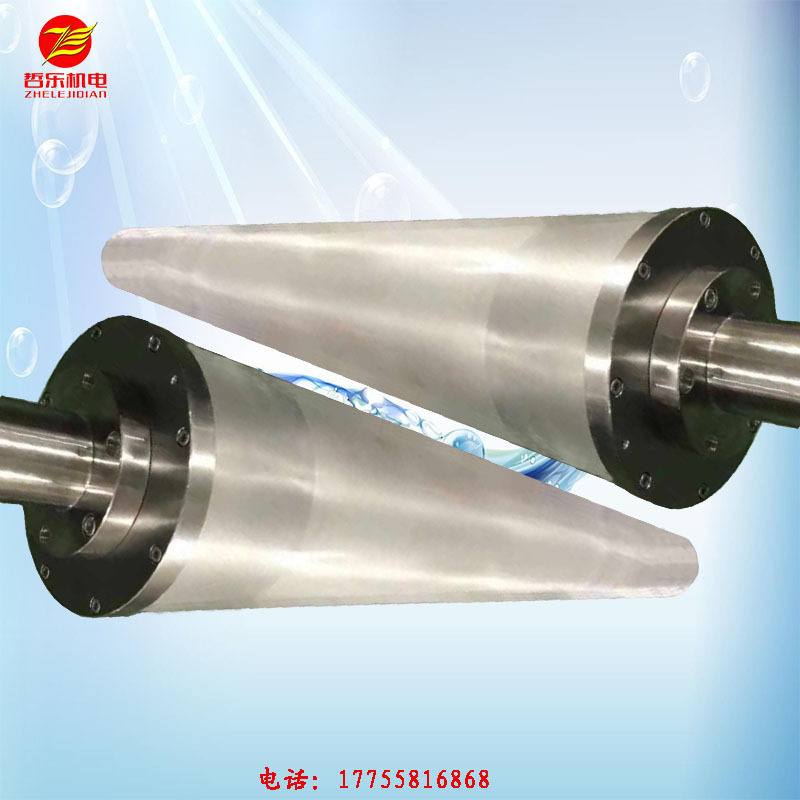

high precision anodized aluminum roller for printing machine

-

Application:

-

Industrial Equipment

-

Process:

-

Forging+machining+heating Treatment

-

Name:

-

Stainless Steel Cnc Machining Shaft

-

Type:

-

Machining Services

-

Surface Treatment:

-

Chrome Plating

-

Size:

-

Clients Drawings

-

Material Capabilities:

-

Aluminum

-

Quality:

-

High Precision

Quick Details

-

Weight (KG):

-

20

-

Material:

-

100% Steel, Steel, Aluminum Roller, Cast Aluminum

-

Torque Capacity:

-

Custom-Making

-

Model Number:

-

zle06

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

zhele

-

Product name:

-

high precision anodized aluminum roller for printing machine

-

Application:

-

Industrial Equipment

-

Process:

-

Forging+machining+heating Treatment

-

Name:

-

Stainless Steel Cnc Machining Shaft

-

Type:

-

Machining Services

-

Surface Treatment:

-

Chrome Plating

-

Size:

-

Clients Drawings

-

Material Capabilities:

-

Aluminum

-

Quality:

-

High Precision

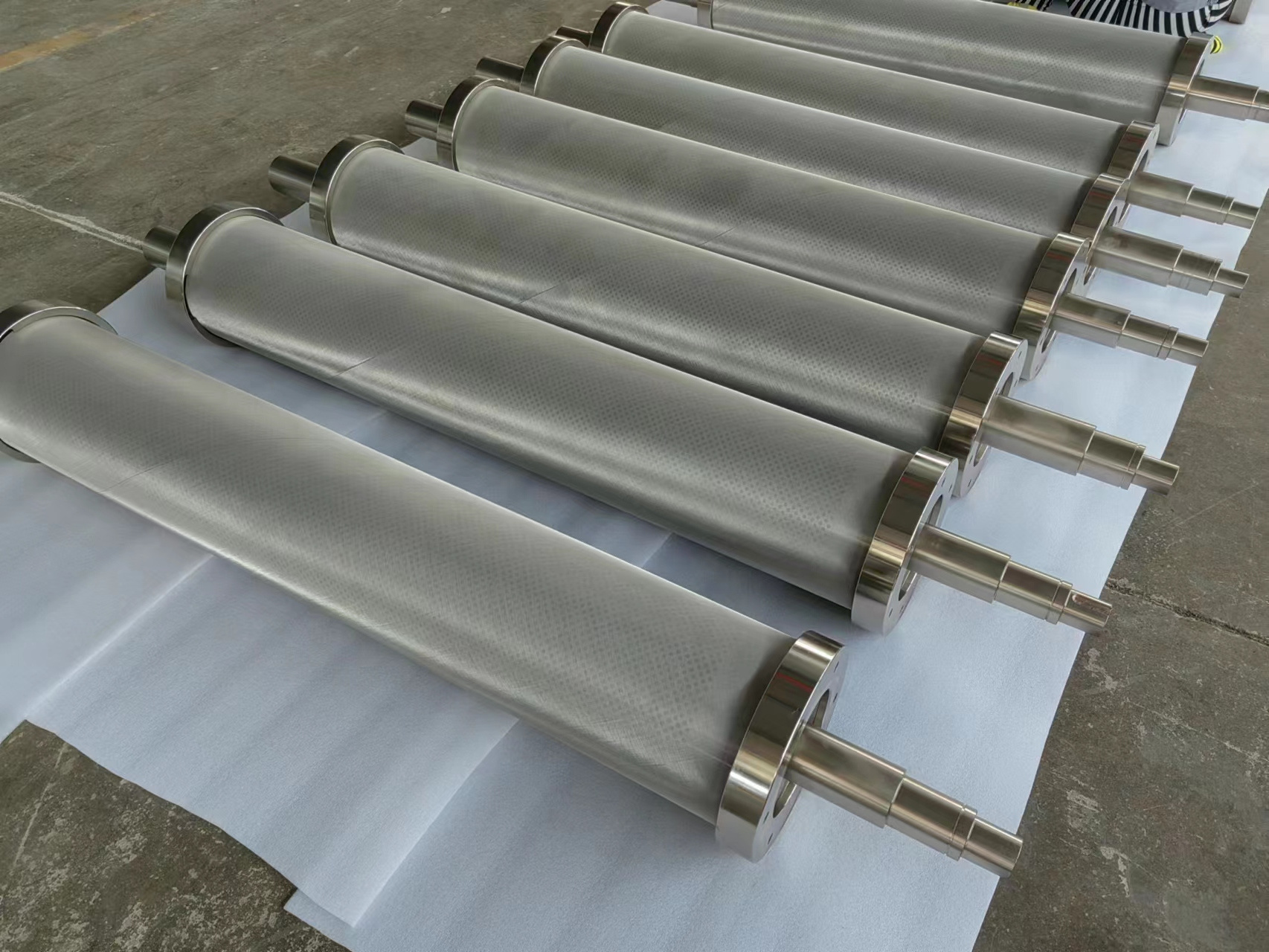

Vacuum roller is also called the vacuum adsorption roller is a kind of rolling equipment used in the film charge adsorption roller, it is different the ordinary double roller, vacuum roller of roller surface sets through the suction hole on the surface of the roller, the roller with suction device, suction device is equipped with front roller lining of inspiratory mouth, as the rotation of roller relative to inspiratory element on the surface of the roller suction hole periodically after inhaling the intake of the element.

Two, vacuum roller adsorption roller

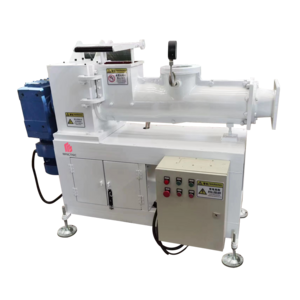

When the product coil is not suitable for double-sided contact, can not adopt clamp roller design, the invention of vacuum roller for you to provide the ideal solution. At the same time, the vacuum adsorption roller can be installed in front of the air floating oven (a kind of equipment suitable for double-sided coating of the coil), is an excellent tension isolation and control point. The vacuum roller absorbs the coil through the vacuum to make it close to the cylinder, increasing the friction force and preventing the slip of the coil.

Three, vacuum roller characteristics

1, flexible selection: compared with ordinary transfer roller, its adsorption contact area of the carrier is 5-10 times higher, greatly improving the work efficiency, and can choose different adsorption strength according to the weight of different carriers,

2, anti dust into: compared with the traditional transfer roller, the roller's special technology, to prevent dust and other foreign matter inhalation, greatly improve the service life;

3, vacuum adsorption: solve the problem of film fracture in the process of stretching, thin material has constant traction. Realize the best choice of traction in the process of coating and coiling.

The invention of vacuum adsorption roller has solved the problem that ultra-thin coil cannot be rewound by double-sided roller, ensuring the product rate and production efficiency of thin film coil. It is a kind of practical application of high and new technology in production. Guangzhou Furuda Industrial technology has been carrying out technological innovation, which has injected new vitality into the further capacity improvement of new energy vehicles. It can be said that the vacuum traction roller is indispensable.

Three, vacuum roller characteristics

1, flexible selection: compared with ordinary transfer roller, its adsorption contact area of the carrier is 5-10 times higher, greatly improving the work efficiency, and can choose different adsorption strength according to the weight of different carriers,

2, anti dust into: compared with the traditional transfer roller, the roller's special technology, to prevent dust and other foreign matter inhalation, greatly improve the service life;

3, vacuum adsorption: solve the problem of film fracture in the process of stretching, thin material has constant traction. Realize the best choice of traction in the process of coating and coiling.

The invention of vacuum adsorption roller has solved the problem that ultra-thin coil cannot be rewound by double-sided roller, ensuring the product rate and production efficiency of thin film coil. It is a kind of practical application of high and new technology in production. Guangzhou Furuda Industrial technology has been carrying out technological innovation, which has injected new vitality into the further capacity improvement of new energy vehicles. It can be said that the vacuum traction roller is indispensable.