- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HT-002

-

Usage:

-

Mass finishing polishing, Metal polishing

-

Color:

-

White, green, yellow and customize

-

Certificate:

-

ISO9001:2008

-

Density:

-

2.5-3.6g/ml

-

Mesh:

-

200#-2000#

-

Packing:

-

25kg/bag

-

Shape:

-

SCT, ACT, SCC, ACC, SCE, ACTS & customize

-

Feature:

-

High density low consumption

Quick Details

-

Abrasive Grain Sizes:

-

2000#

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HT

-

Model Number:

-

HT-002

-

Usage:

-

Mass finishing polishing, Metal polishing

-

Color:

-

White, green, yellow and customize

-

Certificate:

-

ISO9001:2008

-

Density:

-

2.5-3.6g/ml

-

Mesh:

-

200#-2000#

-

Packing:

-

25kg/bag

-

Shape:

-

SCT, ACT, SCC, ACC, SCE, ACTS & customize

-

Feature:

-

High density low consumption

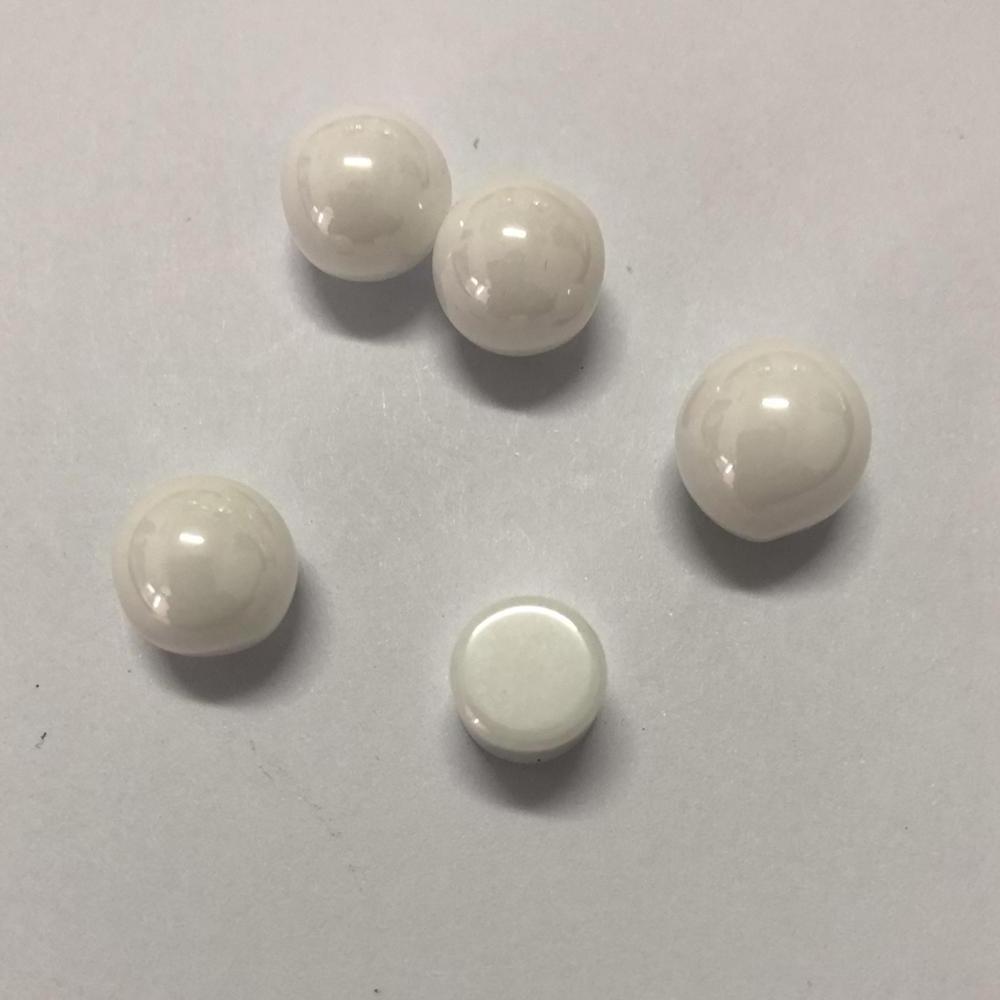

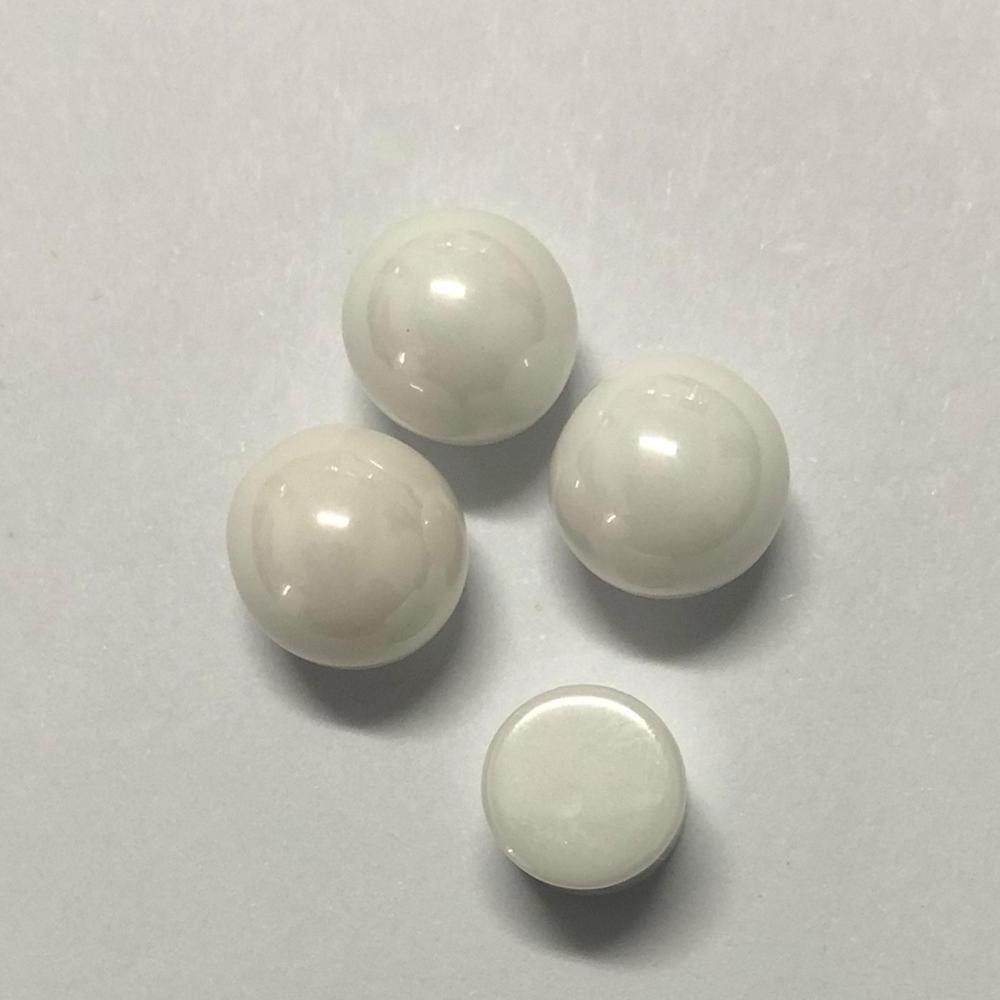

Zirconia ZrO2 beads grinding media yttria stabilized zirconium oxide zirconia ceramic ball

Ceramic grinding material, abrasive media, deburring media, polishing consumables, high density ceramic polishing grains. We produce all kinds of mass polishing media material, ceramic media for fine polishing, porcelain polishing, light cutting, medium cutting, general cutting, fast cutting, very fast cutting and other types.

All shape are available for production, or we produce the exactly same media according to client's sample, like ball, cylinder, angle cut cylinder(ACC), triangle, angle cut triangle(ACT), tri-star, grain, cone, etc.

We have professional technical team, to recommend the right abrasive material with right shape based on the polishing product's material and polishing needs for our clients. This is the most important and the key for consumables products selection.

For other special shape or specification polishing media, we can provide customize production according to our clients' sample. Shape, size or color never be a problem for us.

All kind of shapes available:

| BALL | SCT | ACT | SCC | ACC | SCE | ACTS | |||

| φa(mm) | a*b(mm) | a*b(mm) | a*b(mm) | a*b(mm) | a*b*c(mm) | a*b(mm) | |||

| φ1 | φ10 | 3*3 | 12*12 | 2*2 | 10*10 | 3*6 | 3*6 | 10*10*6 | 8*8 |

|

φ2 |

φ12 | 4*4 | 15*15 | 3*3 | 12*12 | 3*10 | 4*8 | 12*16*8 | 10*10 |

| φ3 | φ14 | 5*5 | 20*20 | 4*4 | 15*15 | 4*10 | 5*10 | 16*18*10 | 12*12 |

| φ4 | φ15 | 6*6 | 25*25 | 5*5 | 20*20 | 5*16 | 6*10 | 20*25*12 | 15*15 |

| φ5 | φ18 | 8*8 | 30*30 | 6*6 | 25*25 | 8*16 | 6*12 | / | 20*20 |

| φ6 | φ20 | 10*10 | / | 8*8 | 30*30 | / | 8*16 | / | 25*25 |

Our company has more than 50 patents, also certified by ISO9001-2015,ISO14001-2015. We been in this industry for more than 25 years. We committed to produce high quality products, and focus on high-end market, never lower product quality to fighting on prices.

We have strict production procedures and thorough quality control system, to produce the high quality and perfect ceramic grinding material.

1. Our own patent and confidential formula, fully mix raw materials. 2. Fully mix with appropriate percentage water, and make raw block

3. Use different shape mould to extrude exact shape strings. 4. Cut the strings size & angle according to signed order.

5. Airing and dry the abrasive grains. 6. 1400 dgr stove to finalize the products.

7. Filter out the off-size grains. 8. Use two size filter screen do final filtrate, make every unit perfect.

9. Packing the material, mostly 25kg/woven bag. 10. Stock in our warehouse waiting for shipment.

Standard packing in 25KG/woven bag. 40 bags/pallet. Any other special customized packing available.

Our services and advantages.

1. ISO certified company, thorough quality control system. Same price level, we have better quality.

2. Cutting material by machine, get perfect angle. Also under supervison of worker, to pick out the off-size grains, make sure all units are perfect.

3. Small stove finalize the abrasive material, make all units be heated evenly, to guarantee the quality.

4. Any shape abrasive customize available, just send us a sample, we can work out the same thing.

Our certifications: