- Product Details

- {{item.text}}

Quick Details

-

Power:

-

No

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

350 KG

-

Machinery Capacity:

-

1000-30000l/day with different configuration

-

Appearance:

-

Stainless steel

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Color Available:

-

Mirror SUS/2B

-

Heating:

-

No

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.2-0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

Temperature, Pressure auto control

-

Plants Type:

-

Turnkey or Customerized

-

Accessories:

-

Available for stainless steel fermenter

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TIANTAI

-

Voltage:

-

220V/380V

-

Power:

-

No

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

350 KG

-

Machinery Capacity:

-

1000-30000l/day with different configuration

-

Appearance:

-

Stainless steel

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Color Available:

-

Mirror SUS/2B

-

Heating:

-

No

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.2-0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

Temperature, Pressure auto control

-

Plants Type:

-

Turnkey or Customerized

-

Accessories:

-

Available for stainless steel fermenter

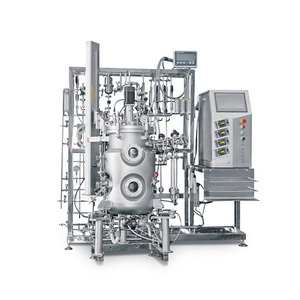

The jacketed conical fermenter is defined as a standard in the whole micro brewery area. Conical bottom is convenient for recycling the yeast after finishing the fermenting. Glycol jacket is used for cooling down the temperature of fermentation vessel. The temperature of fermenting can be evenly decreased while glycol water is running inside the jackets wrapped around the fermenter. Usually there are 2 or 3 section jacket on the cylinder of fermentation tank and 1 section on bottom. The jacketed conical fermenter can combine the fermentation and maturation processes into one vessel mounted with a carbonation stone.

Function:Wort Stainless steel fermenter

Interior Shell: SUS304 full welded; TH=3mm

Exterior Shell:SUS304 full welded; TH=2mm

100% TIG welding with pure argon gas shield

Insulation: Polyurethane; TH=80mm

Double zone glycol jacket

Completed with CIP ball, pressure relief and vacuum valve, pressure gauge,

beer racking port, draining port, sampling port and manway

|

|

Volume in US Gallon |

Diameter |

Height |

|

5HL Stainless steel fermenter |

132US Gallon |

1010mm |

2100mm |

|

6HL Stainless steel fermenter |

159US Gallon |

1060mm |

2150mm |

|

8HL Stainless steel fermenter |

211US Gallon |

1060mm |

2550mm |

|

10HL Stainless steel fermenter |

264US Gallon |

1210mm |

2550mm |

|

12HL Stainless steel fermenter |

317US Gallon |

1360mm |

2550mm |

|

15HL Stainless steel fermenter |

396US Gallon |

1560mm |

2620mm |

|

20HL Stainless steel fermenter |

528US Gallon |

1560mm |

3100mm |

|

25HL Stainless steel fermenter |

660US Gallon |

1560mm |

3450mm |

|

30HL Stainless steel fermenter |

793US Gallon |

1760mm |

3500mm |

|

35HL Stainless steel fermenter |

925US Gallon |

1760mm |

3750mm |

|

40HL Stainless steel fermenter |

1057US Gallon |

1760mm |

4050mm |

|

50HL Stainless steel fermenter |

1321US Gallon |

1760mm |

4540mm |

|

60HL Fermentation Tank |

1585US Gallon |

1960mm |

4700mm |

|

70HL Stainless steel fermenter |

1849US Gallon |

1960mm |

5200mm |

|

100HL Stainless steel fermenter |

2642US Gallon |

2250mm |

5700mm |

|

150HL Stainless steel fermenter |

3963US Gallon |

2250mm |

7550mm |

a.) Free consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Free debugging instruction of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques;

g.) Provide 36 months complete warrantee for tanks body and life-time maintenance service; All of the accessories

and auxuliaries facilities are guaranteed for one year; The seller is responsible for the nature damage of

the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are

attached with the machinery for free.