It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the

extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into

the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing

area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further

stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random

nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile

strength and elongation of the final product. After cooling, the material can be wound.

- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Hospital, Agriculture, Bag, Garment, Car, Industry

-

Weight:

-

9gsm~260gsm, 10gsm-260gsm, 18g/m2-240g/m2

-

Place of Origin:

-

China

-

Brand Name:

-

Lianyi Nonwoven Fabric

-

Model Number:

-

9gsm~260gsm, 10gsm-260gsm, 18g/m2-240g/m2

-

Certification:

-

CE

-

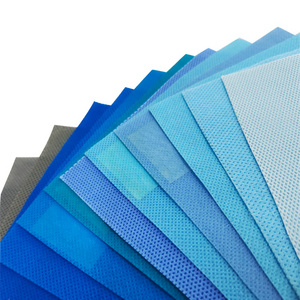

Color:

-

Customer's Request

-

Product name:

-

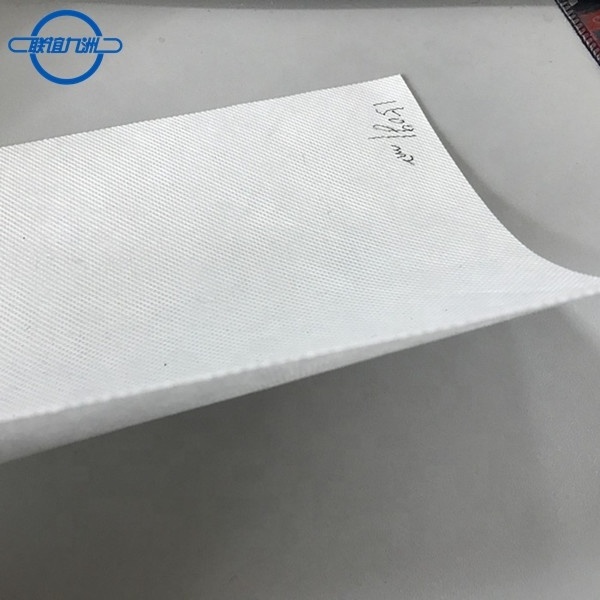

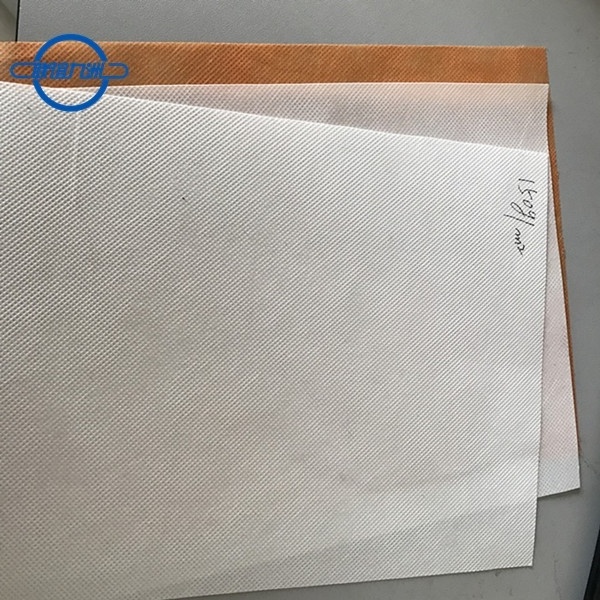

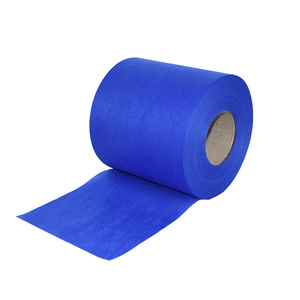

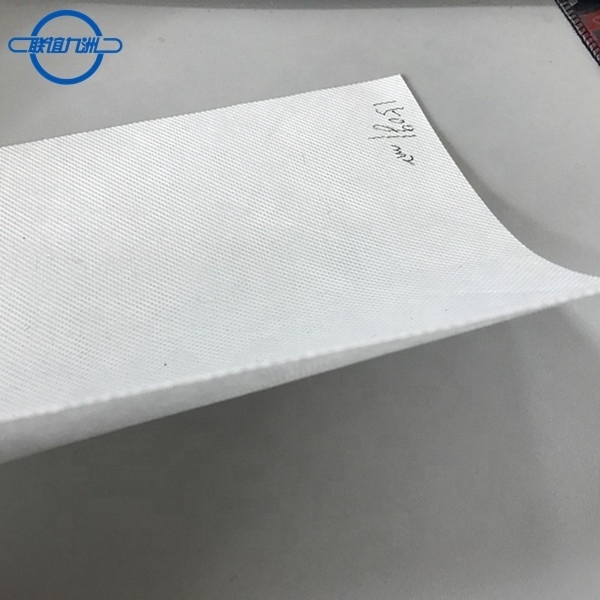

Polyester Spunbond Nonwoven Fabric

-

Application:

-

Hospital

-

Roll Length:

-

Max 7500m

Quick Details

-

Material:

-

100% Polyester

-

Pattern:

-

Dyed

-

Feature:

-

Waterproof

-

Use:

-

Hospital, Agriculture, Bag, Garment, Car, Industry

-

Weight:

-

9gsm~260gsm, 10gsm-260gsm, 18g/m2-240g/m2

-

Place of Origin:

-

China

-

Brand Name:

-

Lianyi Nonwoven Fabric

-

Model Number:

-

9gsm~260gsm, 10gsm-260gsm, 18g/m2-240g/m2

-

Certification:

-

CE

-

Color:

-

Customer's Request

-

Product name:

-

Polyester Spunbond Nonwoven Fabric

-

Application:

-

Hospital

-

Roll Length:

-

Max 7500m

Products Description

Polyester Spunbond Nonwoven Fabric

Manufacturing Technique

Recommend Products

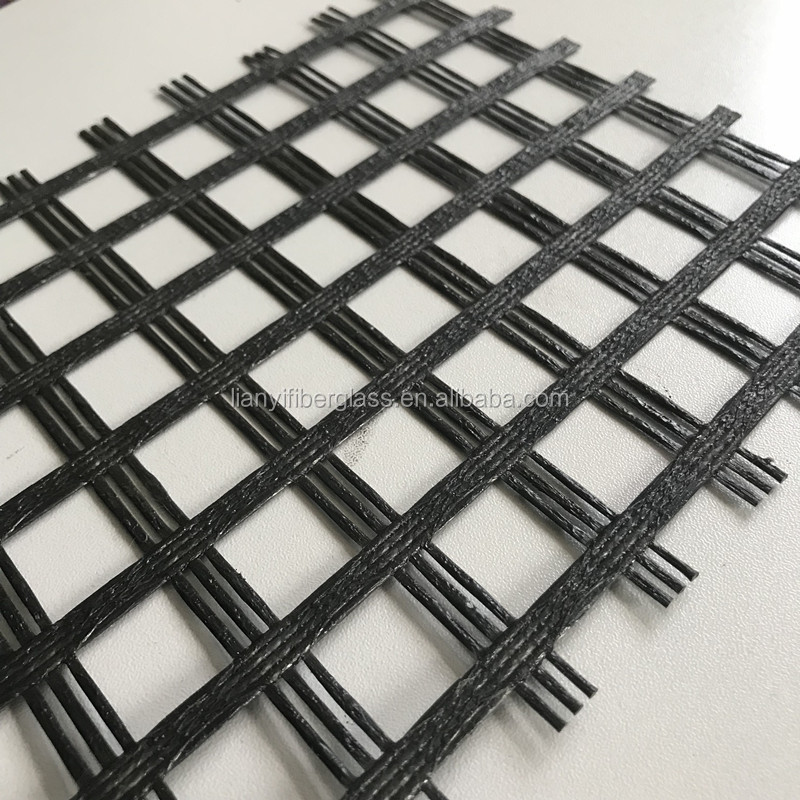

Fiberglass Geogrid

Polyester Geogrid

Fiberglass Geogrid/PET Geogrid Composite with Nonwoven Geotextile

Fiberglass Geogrid/PET Geogrid Stitched with Nonwoven Geotextile

PP Biaxial Geogrid

PP Biaxial Geogrid Composite with Nonwoven Geotextile

PP/HDPE Uniaxial Geogrid

PP/PET Needlepunched Nonwoven Geotextile

PET Spunbond Nonwoven Fabric

HDPE Geocell

HDPE Geomembrane

Geotextile Composite with Geomembrane

Hot Searches