- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3 kw

-

Material:

-

stainless steel or iron material

-

Dimension:

-

920*780*2050 mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Model:

-

DV-400 Pig head cutting machine

-

Capacity:

-

400 pcs/h

-

Power:

-

3 kw

-

Material:

-

stainless steel or iron material

-

Dimension:

-

920*780*2050 mm

Pig Splitting Machine Pig Cow Head Cutter Cutting Machine

Cattle Sheep Head Cutting Sawing Slaughtering Machine Pig Head Halve Cutting Split Machine

Description of the pig head cutting machine

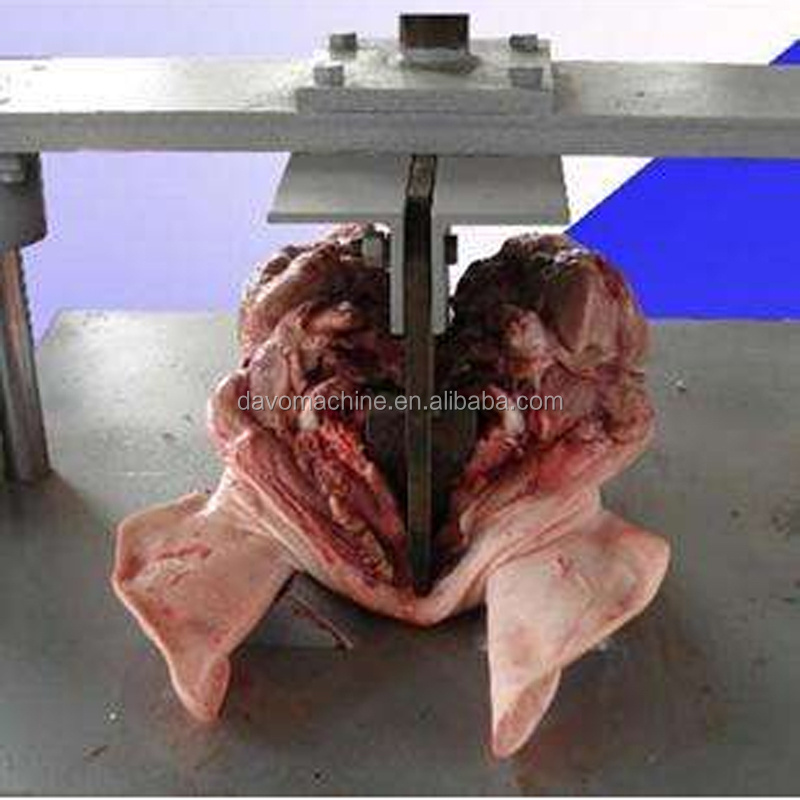

1. Pig's head, sheep's head and ox's head splitting machine is a kind of special splitting processing equipment designed by hydraulic working principle.

2. Use the oil cylinder to drive the knife rest up and down to split the pig's head in half and leave the pig's brain intact.

3. The slide of the tool rest adopts axle sleeve design, small clearance, pig head splitting machine, stable work, long service life of oil cylinder, no oil leakage.

4. The blade is made of 50mm×60mm manganese steel no. 65 thick. It is durable and does not bend.

5. The platform is made of 22mm stainless steel plate, which is rugged and durable.

6. The stroke of the tool rest is positioned by the stroke switch and can be stopped at any position.

7. T he use of hydraulic operation button, stop can automatically return. Material for stainless steel, durable, other materials easy to corrosion and rust, the use of stainless steel can be more durable, hydraulic control, foot switch, simple operation, save time and effort .

Application

It is suitable for splitting pig head, goat head, whole chicken etc.

Technical data of the pig head splitting machine

|

Model |

DV-400 |

|

Capacity |

400 pcs/h |

|

Power |

3 kw |

|

Dimension |

920*780*2050 mm |

|

Weight |

200 kg |

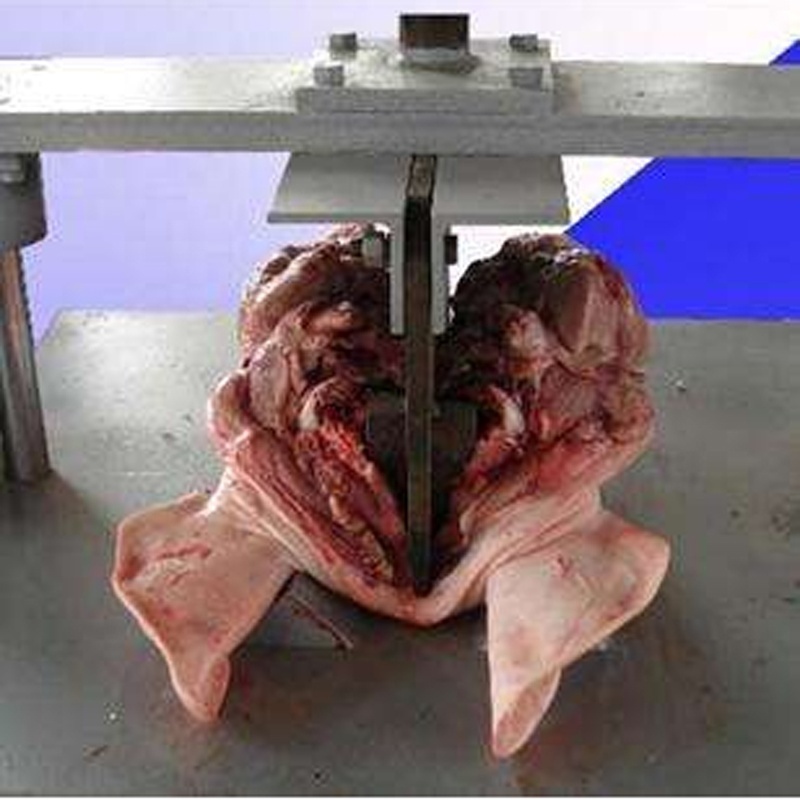

Photos of the pig head splitting machine

Packaging

1. First damp-proof packing. ( film wrap to prevent moisture by sea)

2. Then packed the machine into ply-wood case. (non-fumigation wooden box)

Shipping

1. By sea ( FCL or LCL are both ok)

2. By air or by express

3. By truck

|

Customized Service |

1. We can design our machines depends on customers’ demands to meet different needs of customers. 2. Customized moulds and size, customized voltage. |

|

Team Strength |

1. We can provide customers complete sales, consulting, installation, maintenance of the continuous line services . 2. Well trained sales team. professional staff with efficient communication to recommend the most suitable machine to customers. 3. Update timely on order status such as starting the order, processing the order till the order completion. |

|

Quality inspection |

1. Stable raw material purchasing . 2. Before shipping the machine, our woker will test and make sure they are in good condition. |

|

After-sales Service |

1. Operation video & instruction will be sent to clients by email or together with the machine. 2. Spare parts provided. Engineers are available to service machinery overs. |