- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

14.5 kW

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FANGYUAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2040*1250*630

-

Weight (T):

-

6 T

-

Applicable Industries:

-

Building

-

After-sales Service Provided:

-

Overseas service center available

-

Certification:

-

ISO9001/CE

-

Processing:

-

automatic cement block moulding machine

-

HS code:

-

84778000

-

Application:

-

3d panel,sandwich panel,wall panel insulation

-

Name:

-

eps sandwich panel making machine

-

Block size:

-

2000*1200*1000mm

-

Mould cavity size:

-

2040*1240*1030

-

Steam consumption:

-

30-50kg/cycle

-

After-sales Service:

-

Field installation, commissioning and training

Quick Details

-

Max.Forming Height(mm):

-

1000 mm

-

Forming Width (mm):

-

1200 mm

-

Forming Length (mm):

-

8000 mm

-

Heating Power (kW):

-

14.5 kW

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FANGYUAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2040*1250*630

-

Weight (T):

-

6 T

-

Applicable Industries:

-

Building

-

After-sales Service Provided:

-

Overseas service center available

-

Certification:

-

ISO9001/CE

-

Processing:

-

automatic cement block moulding machine

-

HS code:

-

84778000

-

Application:

-

3d panel,sandwich panel,wall panel insulation

-

Name:

-

eps sandwich panel making machine

-

Block size:

-

2000*1200*1000mm

-

Mould cavity size:

-

2040*1240*1030

-

Steam consumption:

-

30-50kg/cycle

-

After-sales Service:

-

Field installation, commissioning and training

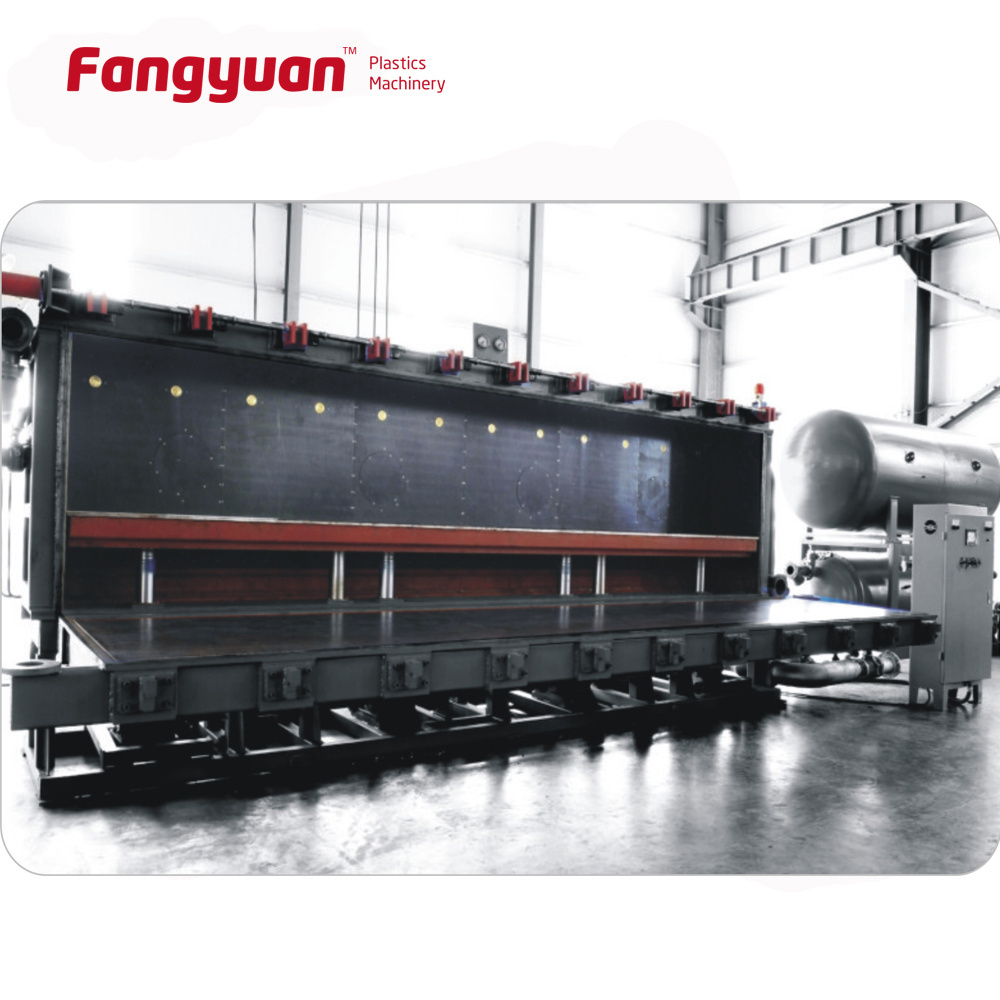

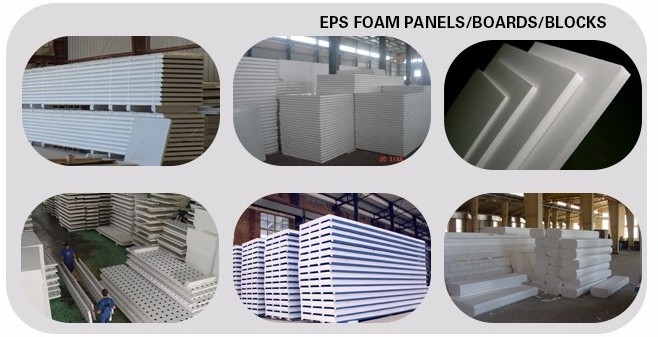

1.Pictures of

eps sandwich panel making machine

2.Technical Data of eps sandwich panel making machine

3.Features of eps sandwich panel making machine

The eps wall panel machine has all advantages and features which is same to DZ/DF block molding machine;

1 .Machine structure:

a, The machine mould are welded by strong rectangle tube and steel plate with high strength frame, keep more safety;

b, All block mould frame are processed by heat-treatment, the welding pressure will be released, so the frame would not deform easier, accurate machining process keep non-leakage;

c, After heating treatment, all mould frame are processed by sand blasting treatment to get rust prevention, so under coat and finishing coat are greatly improved anticorrosion performance and long life;

d, Adopts three Germany gauges and safety valve for double protection, the machine will be water pressure and steam many testing, ensure the machine more stable and safety.

2. Steam system: Adopts three ball valves to take place of one big steam valve (save steam 20%) with ISO-standard butterfly valves, greatly improved stably and long life;

3. Control system:

a, Adopts PLC(Japan Mitsubishi) and touch screen (French Schneider) with easily operation;

b, Equipped with material level sensor for control the filling, the block cooling is controlled by foam pressure sensor, it is realize the filling, heating, cooling and open block mould, the whole working procedure automatically.

4. Vertical frame type: less floor occupied, with good drainage performance, reduced low moisture content of blocks advantage etc.

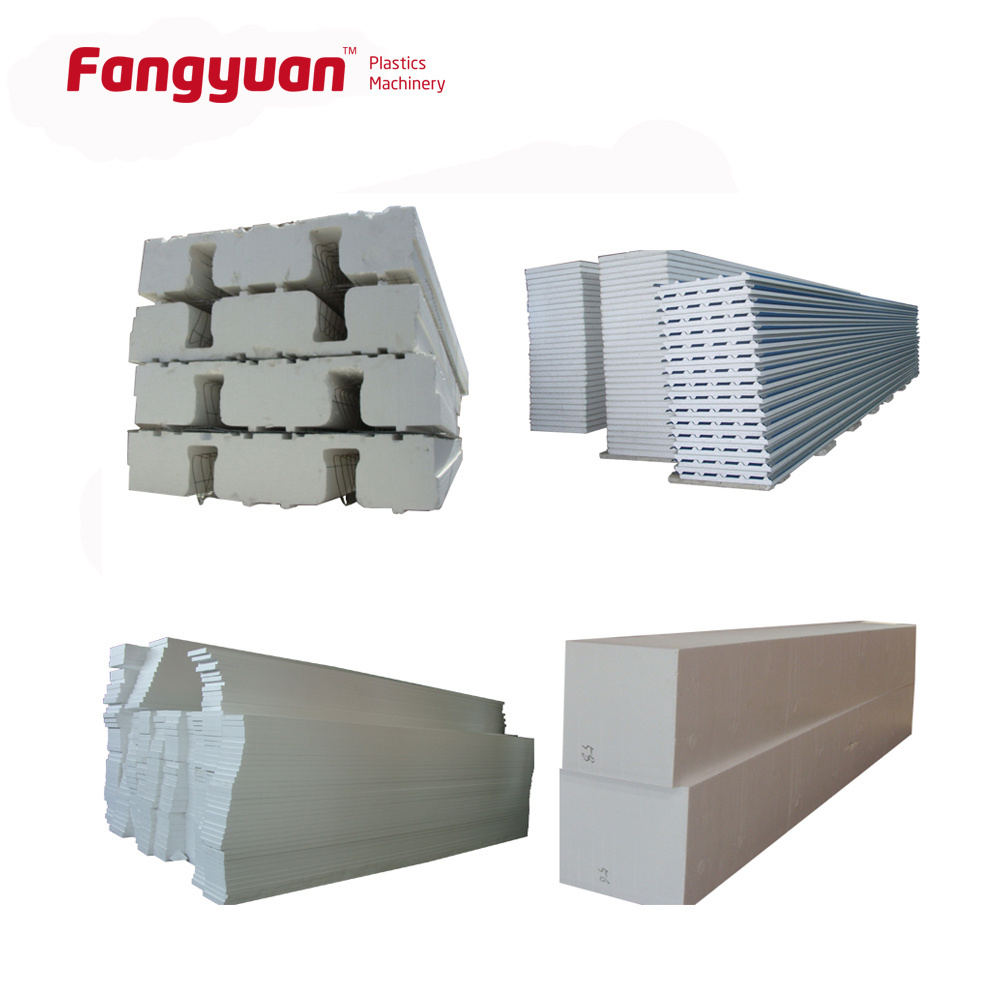

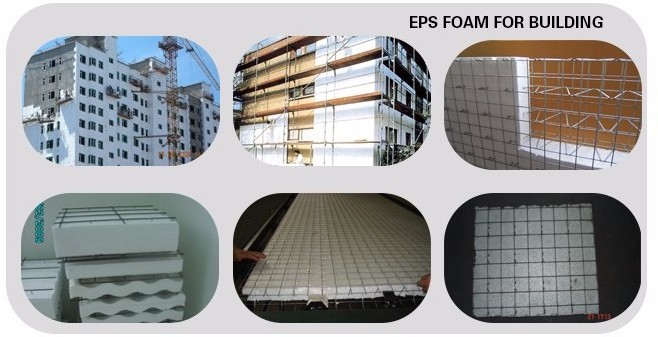

4.Application of eps sandwich panel making machine

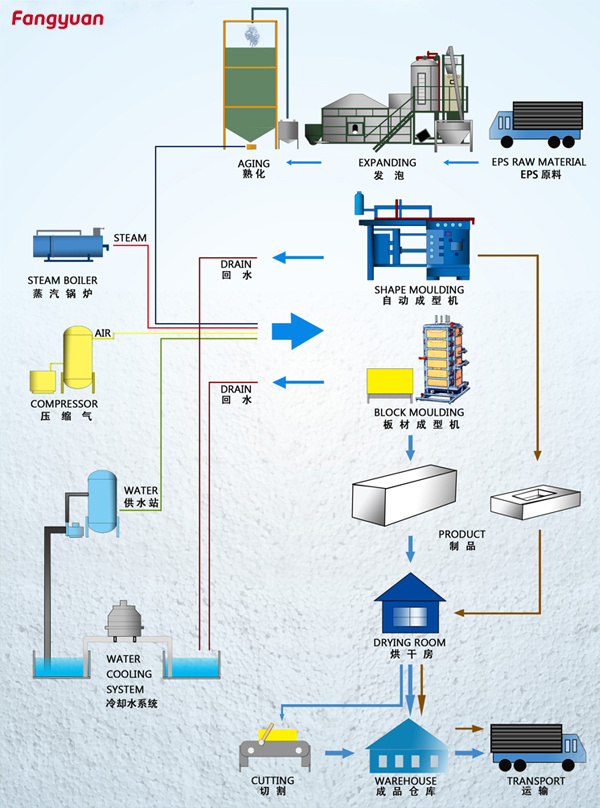

5. eps

product process

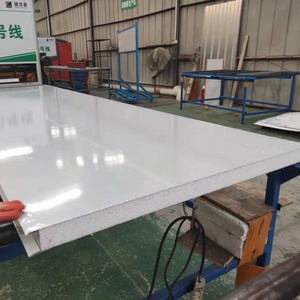

6.The product processing of

eps sandwich panel making machine

Packing : standard exporting package

Shipping port : shanghai/ningb o

WE can provided this service of eps wall panel machine

1. Value clients, guarantee equipment quality and answer clients’ questions anytime and anywhere.

2.

Customizing machines according to clients' inquiry , such as different design, different brand parts, different colors, more function,etc.

3.

Engineers go to clients' factory in time for installation , training and trial production .

4.

More spare parts are given to clients for free to ensure the factory working without suddenly stop.

5. 1 year free warranty, Lifetime technical service support.