- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Lanyu

-

Model Number:

-

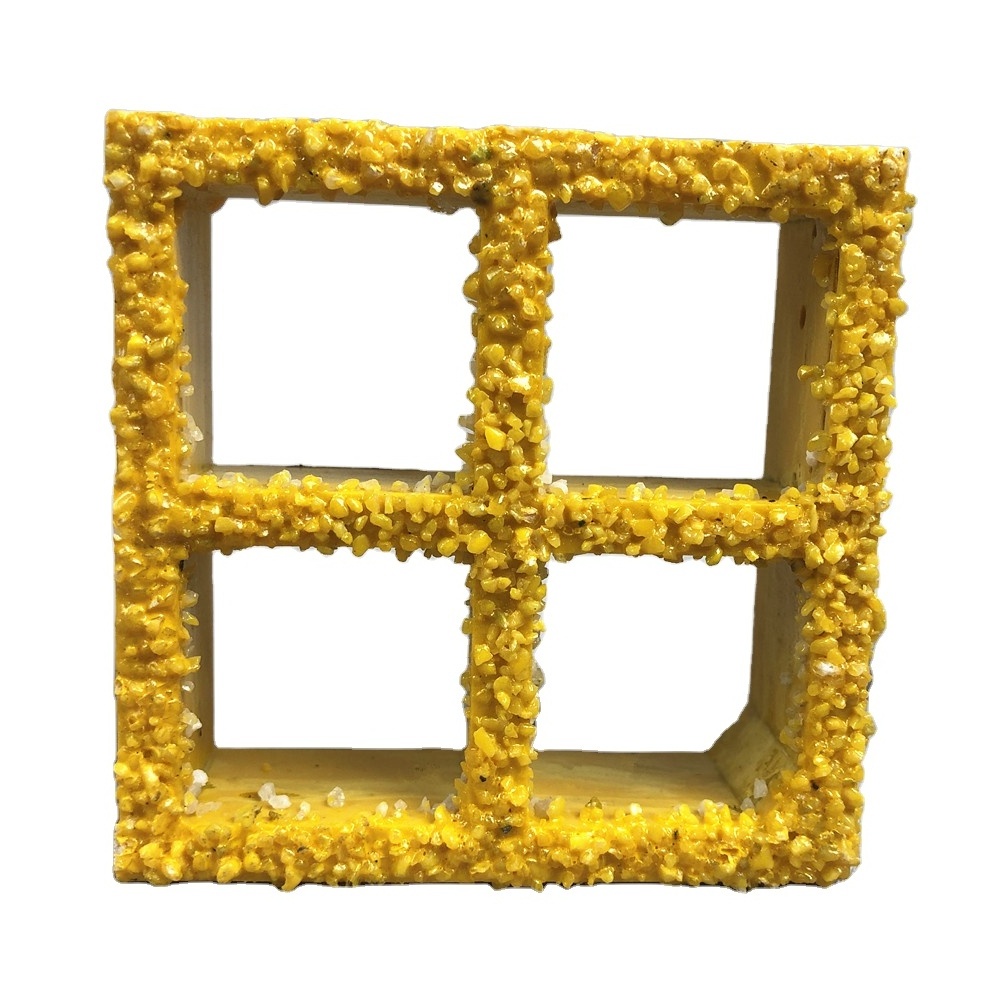

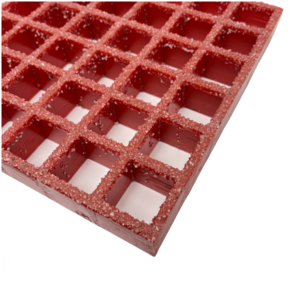

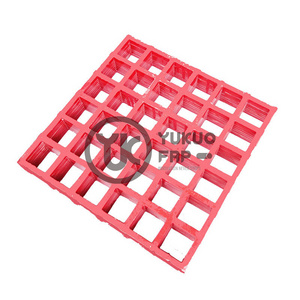

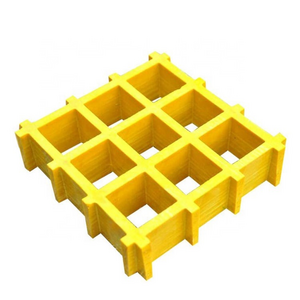

38*38*38mm gritted

-

Surface Treatment:

-

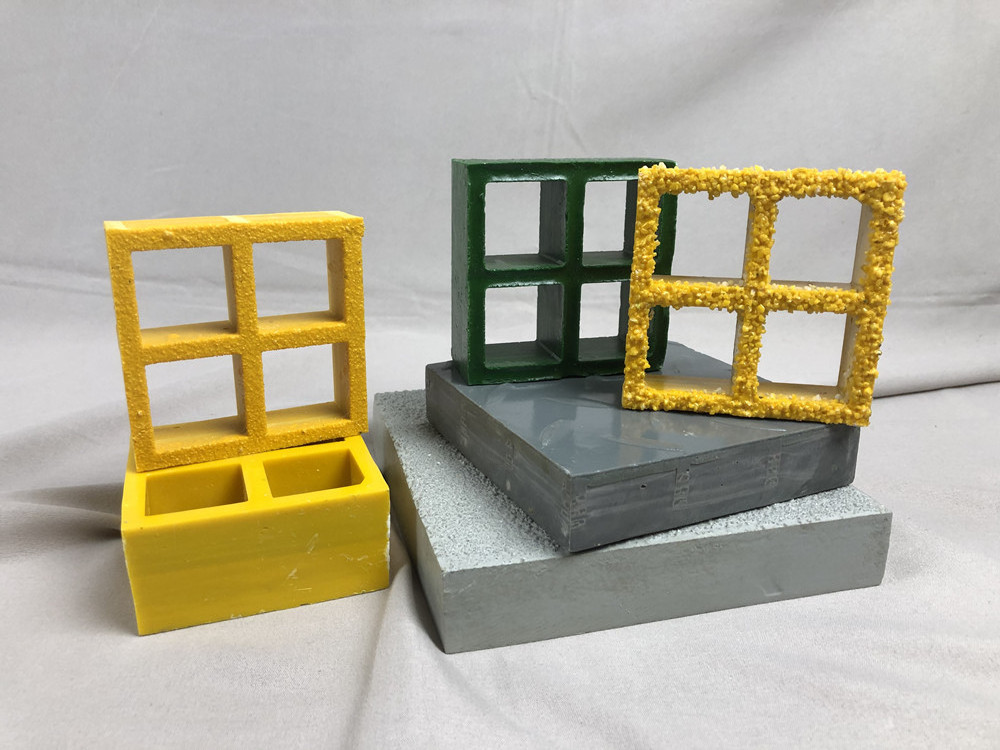

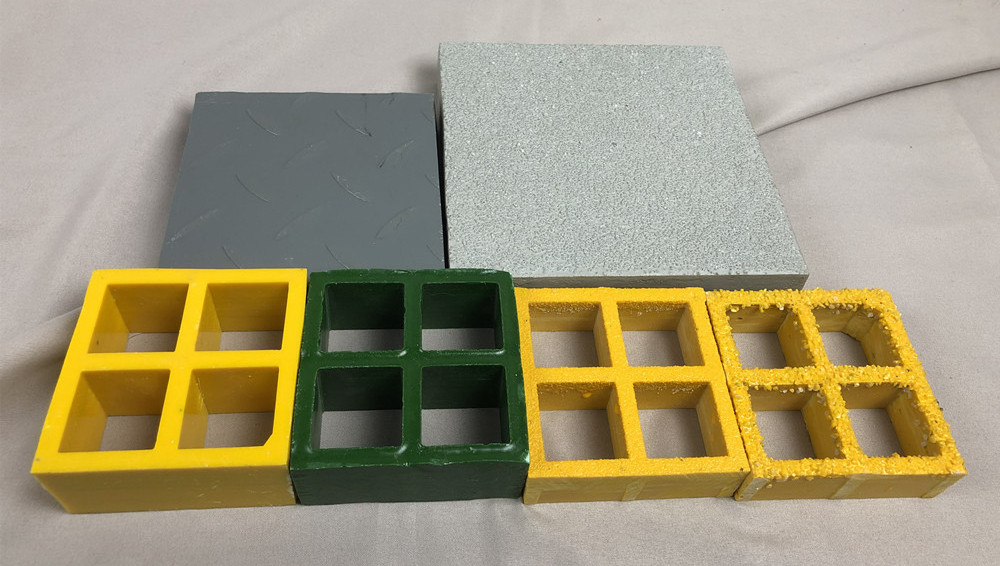

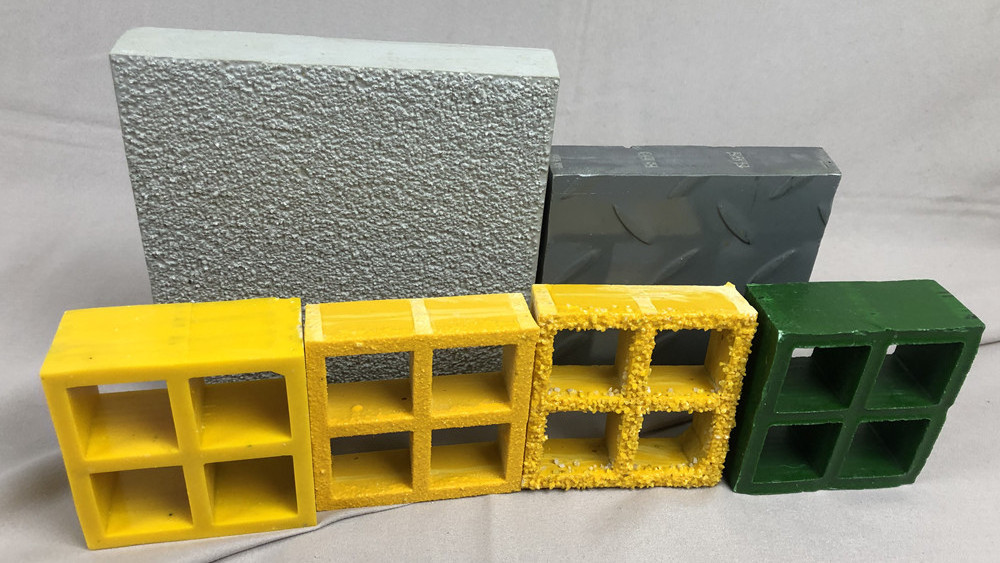

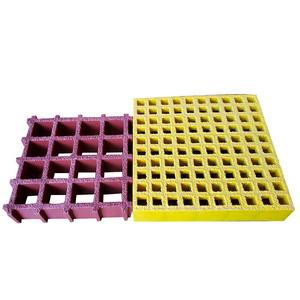

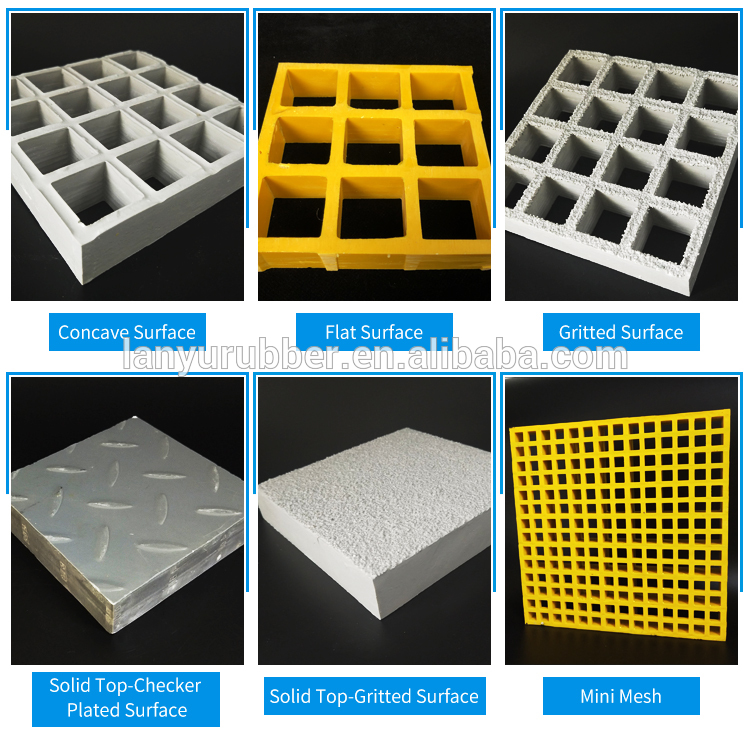

Smooth, gritted, concave

-

Name:

-

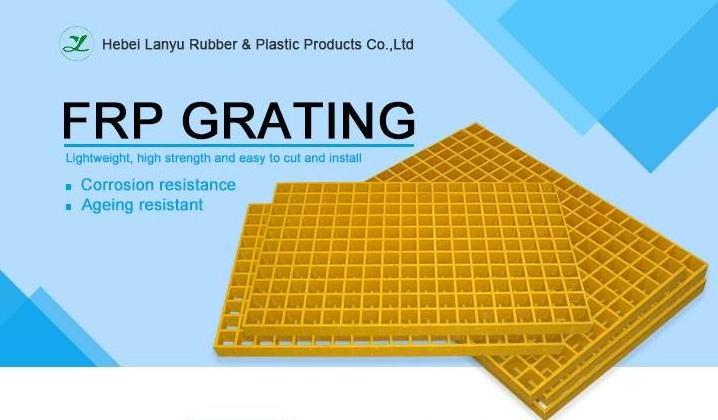

FRP grating

-

Other name:

-

FRP grates, FRP grilling, FRP geogrids

-

Material:

-

Fiberglass, resin

-

Mesh dimension:

-

38*38mm, 50*50mm, 40*40mm

-

Advantage:

-

insulation

-

Sample:

-

Available

-

Feature:

-

High strength, anti-corrosion, anti-slip, anti-fire

-

MOQ:

-

100 square meters

-

Usage:

-

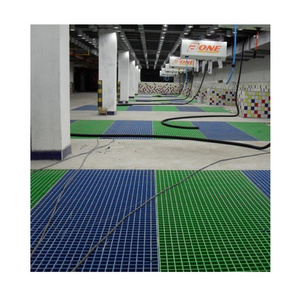

Walkway, gangway, stairs, flatform

-

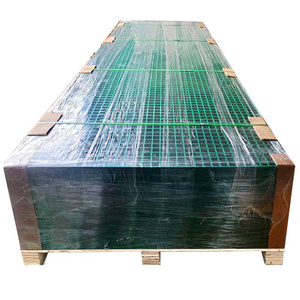

Package:

-

By pallet, wooden case

Quick Details

-

Application:

-

Plant, factory, walkway, stair, roof, floor

-

Technique:

-

Moulding

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Lanyu

-

Model Number:

-

38*38*38mm gritted

-

Surface Treatment:

-

Smooth, gritted, concave

-

Name:

-

FRP grating

-

Other name:

-

FRP grates, FRP grilling, FRP geogrids

-

Material:

-

Fiberglass, resin

-

Mesh dimension:

-

38*38mm, 50*50mm, 40*40mm

-

Advantage:

-

insulation

-

Sample:

-

Available

-

Feature:

-

High strength, anti-corrosion, anti-slip, anti-fire

-

MOQ:

-

100 square meters

-

Usage:

-

Walkway, gangway, stairs, flatform

-

Package:

-

By pallet, wooden case

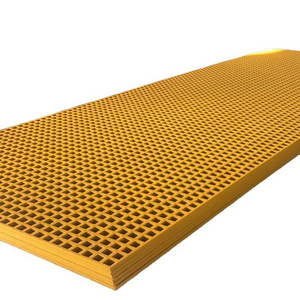

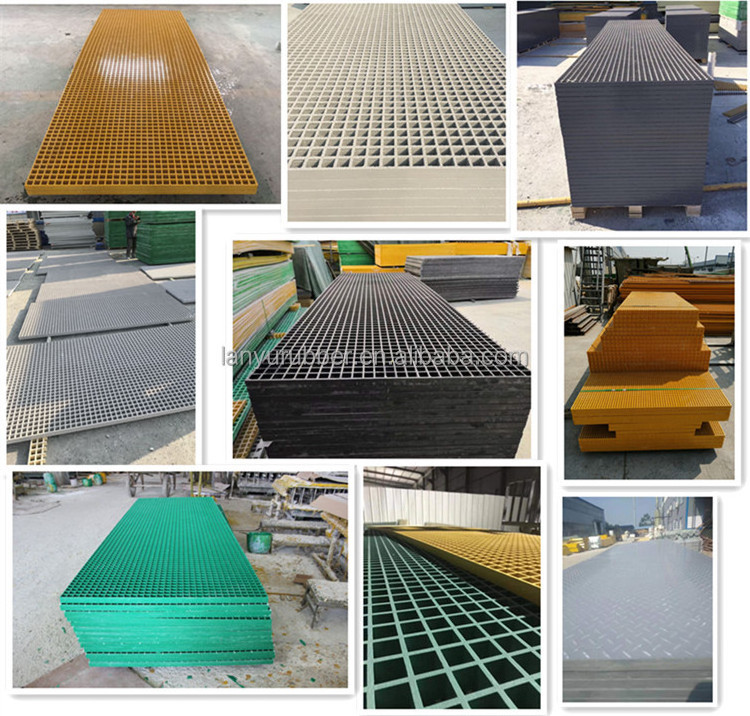

Anti Slip Walkway 0pen Mesh GRP Grating, Fiberglass FRP GRP Molded Grating 38*38mm

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thoroughly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface. Any process such as post applied grit could be bonded after as a secondary operation. This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

|

Name

|

FRP grating

|

|

Material

|

FRP, resin, calcium powder, color toner

|

|

Producing technology

|

Moulding, cutting

|

|

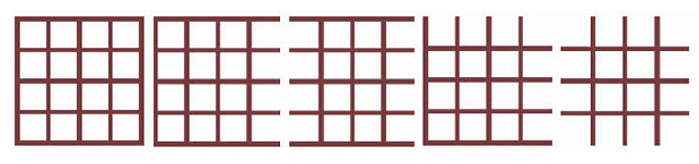

Mesh size and thickness (mm)

|

38*38*25, 38*38*30, 38*38*38, 50*50*50

|

|

Panel size (m)

|

1*3.01, 1*4, 1.22*2.44, 1.22*3.66, 1.22*4

|

|

Surface type

|

Smooth, concave, gritted,

smooth cover, gritted cover, diamond cover |

|

Usage

|

Platform, gangway, walkway, stair, floor, roof, trench cover, fence, etc

|

|

Sample

|

Available

|

|

Customization

|

Accepted

|

Edge Type

Has very excellent acid-proof, alkali resistance, resistance to organic solvents and salt, and many other gas and liquid medium corrosion performance, has the incomparable superiority in the field of anti-corrosion.According to the requirements of the actual use, it is economical to choose the base material for the use of phthalic, polystyrene, and vinyl resin.

Comparing with other floor materials, FRP moulded grating provides a series of benefits, unmatched impact resistance, while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install. FRP moulded grating is made of continuous fiberglass fully soaked in unsaturated polyester resin giving a uniform structure and perfect bi-directional mechanical properties.

Feature

FRP IS UP TO 70% LIGHTER THAN STEEL WITH AN EXCEPTIONAL STRENGTH-TO-WEIGHT RATIO.

Our FRP grating has a high strength-to-weight ratio when compared to traditional materials like metal, concrete and wood. FRP gratings can even be strong enough to carry vehicular loads while weighing less than steel gratings.

FRP IS CORROSION RESISTANT AND REQUIRES LESS MAINTENANCE THAN STEEL.

The durability and corrosion resistance of our FRP gratings and other FRP products reduce or eliminate the need for heavy maintenance like sandblasting, scraping and painting. In fact, many our products are easily cleaned with a high-pressure wash.

PROVIDING A SAFER ALTERNATIVE TO STEEL.

The safety is our highest priority. Our FRP gratings are non-conductive and have a higher friction factor than steel, reducing the risk of electrical shocks and injuries caused by slips. FRP is the clear choice for safer structural products.

LONG SERVICE LIFE

Our gratings provide outstanding durability and corrosion resistance in demanding applications, providing improved product life over traditional materials. The longevity of OUR products provide cost savings over the product’s life cycle. Installed costs are less because of the ease of installation.

LOW INSTALLATION COST

Steel installation can be time consuming and equipment intensive. Our gratings can be easily and quickly cut with ordinary hand tools. Welding or hot work is not necessary with FRP. Our fiberglass gratings are lightweight and can be installed easily with bolts and clips. Installation of FRP material can be done without using heavy equipment and machinery, requiring less manpower.

LIGHT WEIGHT

The lightweight property of our grating results in products that weigh considerably less than steel. The density of steel is four times higher than that of FRP, and steel gratings are two to two-and-a-half times heavier than FRP gratings. FRP’s lighter weight allows easy removal for access below floor level. The reduction in weight that our products provide can save on material transit costs and installation costs.

Production Process

1. Stirring raw materials

2. Pouring material

Pouring the mixed raw materials onto the mold machine corresponding to the FRP grating.

3. Draw yarn

Lay the alkali-free yarn layer by layer to improve the strength of the FRP grating.

4. 4. Compression mold

The stirred raw materials are poured into the mold and compacted mechanically or manually.

5. Heat curing

After the grating is heated for 20 minutes, the raw materials and yarn are fused together.

6. Cooling demoulding, mold lifting

After the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.

Resin, fiberglass fiber yarn, calcium powder filling, color paste, reagents, etc. are arranged in proportion, stirring for 20

minutes.

2. Pouring material

Pouring the mixed raw materials onto the mold machine corresponding to the FRP grating.

3. Draw yarn

Lay the alkali-free yarn layer by layer to improve the strength of the FRP grating.

4. 4. Compression mold

The stirred raw materials are poured into the mold and compacted mechanically or manually.

5. Heat curing

After the grating is heated for 20 minutes, the raw materials and yarn are fused together.

6. Cooling demoulding, mold lifting

After the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.

7. Grinding, painting and washing

The FRP grating is polished and washed with a layer of varnish or water.

The FRP grating is polished and washed with a layer of varnish or water.

Package and Transportation

Fiberglass gratings are packed with pallet or wooden case.

Product Application

>> Industrial areas: such as chemical plants / plating plant operating platform, maintenance platform, photovoltaic power generation platform walkway.

>> Sewage treatment areas: sewage treatment plant aisle and sealing cover.

>> Municipal Engineering areas: Pedestrian Walkway, Trench / Cable Trench Cover, Tree Grating.

>> Marine applications areaa: Boat decks or bridge materials, Offshore oil platform.

>> Other civilian areas: such as car washing, cattle and sheep farms and so on.

Why Choose Us?

1. High Quality:Excellent quality is our first pursue, we have strict quality control by our QC team.

2. Big Capacity:Constantly introducing new equipment to meet clients production requirement and market change.

2. Big Capacity:Constantly introducing new equipment to meet clients production requirement and market change.

3. Professional Team:Professional development team, purchase team, production team, inspection team, sale team, to provide the best service for our customers.

4. High Efficiency:24 hours online service (Email, Trademanager, WhatsApp, Wechat) to solve all your questions.

5. Customization:Size & shape could be made as customer requirement.

6. Payment: Flexible payment ways, making the payment more convenient and easy.

5. Customization:Size & shape could be made as customer requirement.

6. Payment: Flexible payment ways, making the payment more convenient and easy.

FAQ

Q: What’s FRP?

A: Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. The fibers are usually glass, carbon, aramid, or basalt. Rarely, other fibers such as paper or wood or asbestos have been used. The polymer is usually an epoxy, vinylester or polyester thermosetting plastic, and phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, construction industries and ballistic armor.

Q: How do you guarantee your product quality?

A: 100% of our products would be tested before delivery. To control quality, we are using high quality materials from high quality supplier.

Q: Are you a trading company or a manufacturing factory?

A:We are a manufacturing factory with export qualifications. Our factory is one of the best FRP products manufacturer in China. We have FRP products of high quality and various design.

Q: I am interested in your products, could I get a sample for free?

A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is to kindly offer your shipping account.

Q: Can you do the design for us?

A: Yes. With experienced teams in fiberglass product design and manufacturing, we could provide customized shape, dimension, colors service, etc.

Welcome your inquiry, we would provide our best price!

Hot Searches