- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZONXIN

-

Package:

-

Standard Export Package

-

Material:

-

Steel

-

MOQ:

-

1 UNIT

-

Capacity:

-

13000kg

-

Keyword:

-

semi trailer suspension

-

Brand:

-

ZONXIN

-

Product Name:

-

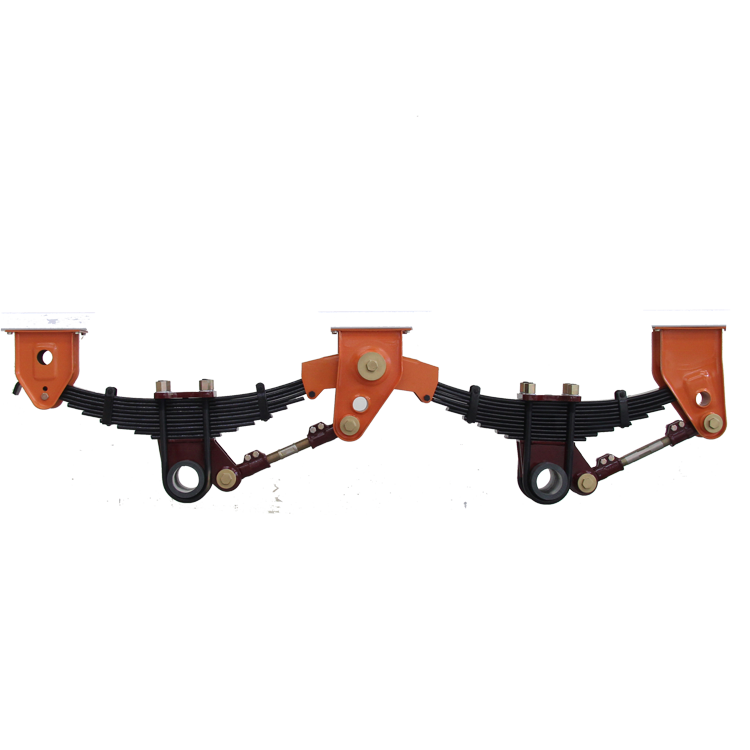

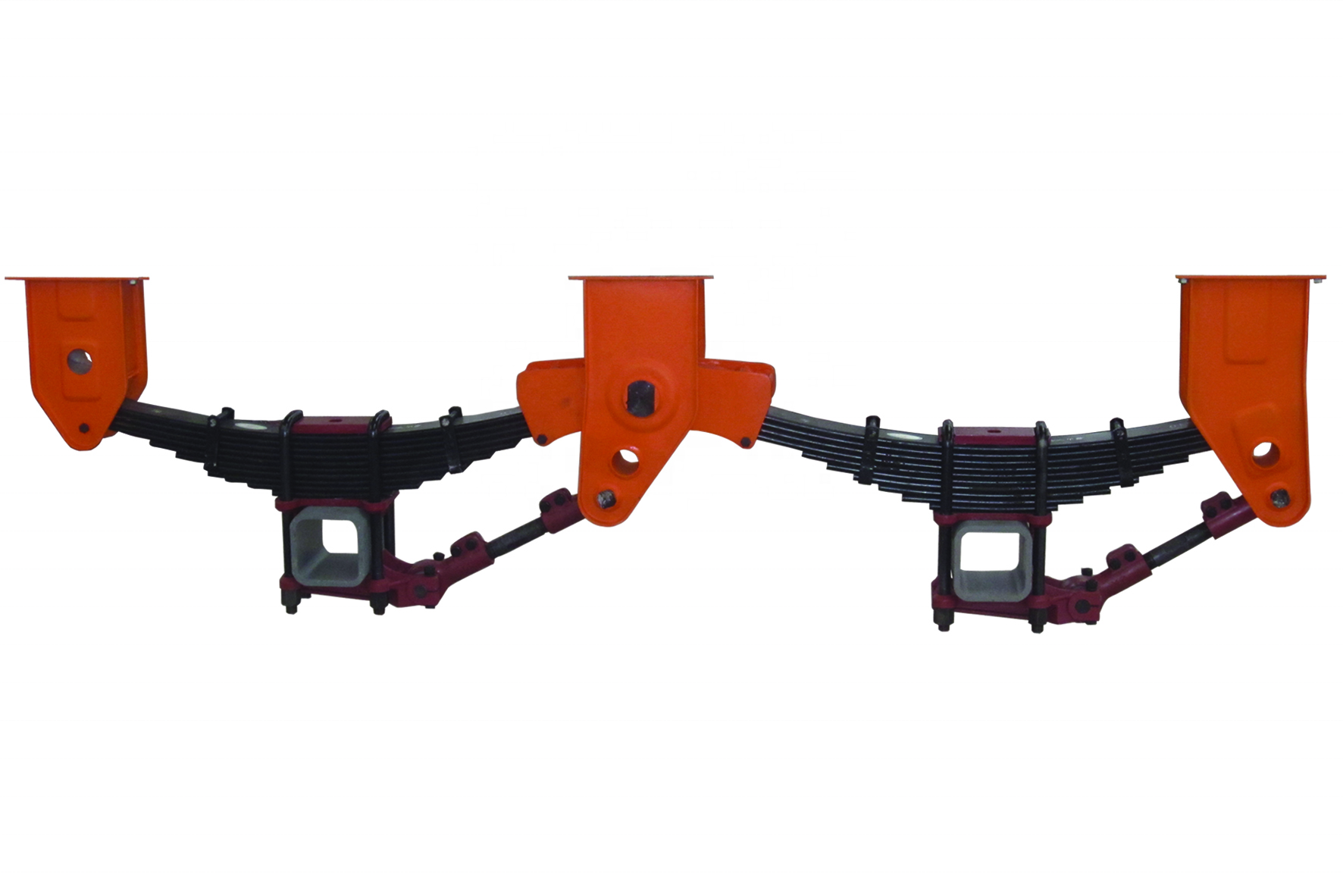

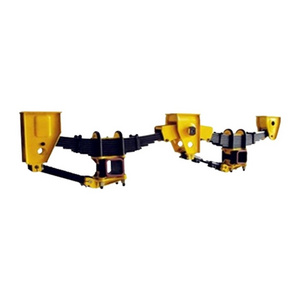

emi Trailer Parts American Type Leaf Spring Suspension 3-axle

-

Color:

-

painted

-

Application:

-

Semitrailer

Quick Details

-

OE NO.:

-

OEM Service Provided

-

Max Payload:

-

13ton

-

Size:

-

13,000*3

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZONXIN

-

Package:

-

Standard Export Package

-

Material:

-

Steel

-

MOQ:

-

1 UNIT

-

Capacity:

-

13000kg

-

Keyword:

-

semi trailer suspension

-

Brand:

-

ZONXIN

-

Product Name:

-

emi Trailer Parts American Type Leaf Spring Suspension 3-axle

-

Color:

-

painted

-

Application:

-

Semitrailer

Specification

Demo drawing

The size can be customized

|

Model

|

Hanger thickness

|

Equalizer thickness

|

Height

|

Equalizer pin

|

Alxe space

|

|

ZXA13.3B6-10OS15-1300

|

6mm

|

10mm

|

110-350mm

|

60mm

|

1300mm

|

|

ZXA13.3B6-12OS15-1300

|

6mm

|

12mm

|

110-350mm

|

60mm

|

1300mm

|

|

ZXA13.3B6-12OS15-1360

|

6mm

|

12mm

|

110-350mm

|

60mm

|

1360mm

|

|

ZXA16.3B8-12OS15-1300

|

8mm

|

12mm

|

110-350mm

|

60mm

|

1300mm

|

|

ZXA20.3C8-12OS15-1310

|

8mm

|

12mm

|

110-350mm

|

60mm

|

1310mm

|

|

ZXA13.2B6-10OS15-1300

|

6mm

|

10mm

|

110-350mm

|

60mm

|

1300mm

|

|

ZXA13.2B6-12OS15-1300

|

6mm

|

12mm

|

110-350mm

|

60mm

|

1300mm

|

|

ZXA13.2B6-12OS15-1360

|

6mm

|

12mm

|

110-350mm

|

60mm

|

1360mm

|

|

ZXA16.2B8-12OS15-1300

|

8mm

|

12mm

|

110-350mm

|

60mm

|

1300mm

|

|

ZXA20.2C8-12OS15-1310

|

8mm

|

12mm

|

110-350mm

|

60mm

|

1310mm

|

Remark: the size can be customized

Advantages of ZONXIN Mechanical Suspension

1.Pins and sleeves are produced by our factory

So we can ensure the matching clearance between the shaft pin and the sleeve, and the shaft pin length is 10 mm longer than the normal one, ensure the matching accuracy requirements

2.Steel castings are produced by our factory

(1)The analysis of the five elements before the furnace processing can ensure 35# steel.

(2)Through normalizing treatment can adjust the internal structure, increase toughness and resistance.

(3)Through destructive testing will thoroughly verify the product quality.

So that we can well control the quality and improve product reliability.

3.The side plate blanking as a whole to ensure the relative position of each hole, so we can well control the machining precision.

4.The left and right side panels are formed at the same time to ensure the consistency of the side panels

5.Reinforcing circles and bushings are automatically welded, it ensures the welding angle and the width of the weld seam, and avoids the problem of bushing cracking caused by weld seam problems

6.During the production, our factory will carry out side plate forming inspection, hanger butt welding inspection, hanger inspection

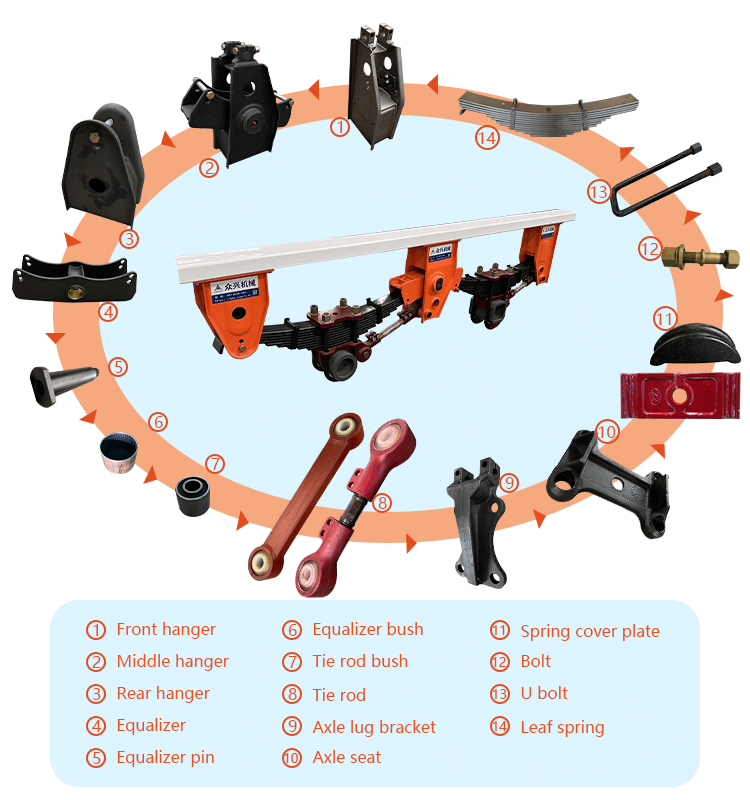

Suspension accessory parts

Hot Searches