- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

180

-

Weight (KG):

-

21000

-

Product name:

-

Metal Vertical Shredder

-

Raw material:

-

Stainless Metal Alloy Aluminum Copper

-

Final product:

-

Metal Granule

-

Hammer head material:

-

Mn18Cr2 cast steel

-

Certification:

-

ISO9001

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Blades material:

-

H13 / 55CrSi

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product

-

Brand Name:

-

Derui Brand

-

Power (kW):

-

180

-

Weight (KG):

-

21000

-

Product name:

-

Metal Vertical Shredder

-

Raw material:

-

Stainless Metal Alloy Aluminum Copper

-

Final product:

-

Metal Granule

-

Hammer head material:

-

Mn18Cr2 cast steel

-

Certification:

-

ISO9001

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Blades material:

-

H13 / 55CrSi

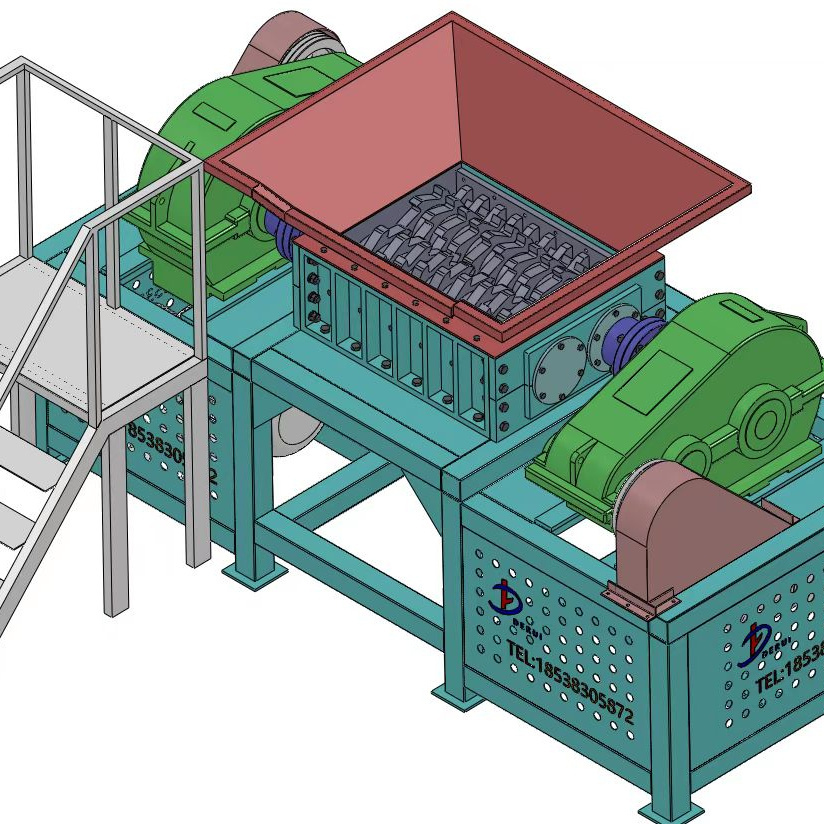

waste metal vertical shredder

Introduction of Vertical Shredder

The new vertical shredder is a new type of scrap metal shredding equipment developed by integrating the domestic and foreign dual-shaft shredder and horizontal shredder technology, and optimized the main functional characteristics. Mainly used for the recycling of non-ferrous metals such as fired iron, waste copper, aluminum and iron slag, motor rotors, copper and aluminum water tank radiators. It has the characteristics of large shredding output, low energy consumption, stable operation, simple structure, convenient operation and maintenance, etc.

Structure

The shredder is mainly composed of bearings, upper machine cover, liner, hammer head, discharge port, hammer plate, base, inspection door, motor, feed port.

Working Principle

The material enters from the feeding hopper and falls into the shredding cavity. It is hit by the high-speed rotating hammer and counter-attacked and rubbed. The material is gradually shredded from large to small. Smaller materials fall into the lower shredding cavity and are beat again by a high-speed rotating compact hammerhead blow. Four shredding chambers repeat the shredding process. Due to the chamber space is small, shear stress is applied to part of the material between the hammer head and the tooth edge of the counterattack plate, milling is carried out, and the fine crushing of the material is accelerated. At the same time, the hammer head carries the material to flow, which produces a great grinding effect between each other, so that the material is further finely shredded until it is shredded to the required particle size.

1. The shredder has low noise and low dust pollution, and can realize the functions of fine shredding and coarse shredding of materials;

2. The overall structure is simple, and the shredding principle of impact and counterattack is adopted, which has the characteristics of high shredding efficiency and low energy consumption;

3. Use high hardness and high toughness materials to forge wear parts, which improves the service life of wear parts and reduces operating costs;

4. The push-type hammer head installation greatly improves the shredding efficiency;

5. A detection door is installed on one side of the machine, which simplifies the daily maintenance process of the composite shredder.

Considering the feeding materials size requirements of the vertical shredder , generally for large scrap steel materials, it can be used with a double-shaft shredder. Please refer to the following production process.

1. Pre-sale support

1) We offer the best solution according to client’s requirement in time.

2) We accept and respect client’s creative idea. We will try our best to integrate client’s idea into the machine and take our years of experience into consideration.

3) We accept client’s sample materials sending for test and take videos.

4) We could offer our technical design before the purchase order.

2. After-sale service

1) Our skilled technicians are available for on-site installation, commissioning & training on request.

2) Dimensional drawings together with service requirements will be provided prior to delivery of the equipment.