- Product Details

- {{item.text}}

Quick Details

-

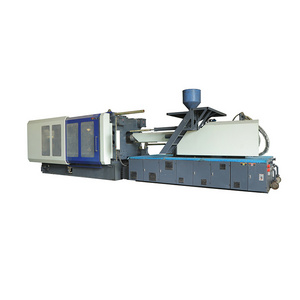

Ejector Force(kN):

-

152 kN

-

Theoretical Shot Volume(cm³):

-

2218 cm³

-

Injection Rate (g/s):

-

545.82 g/s

-

Injection Weight (g):

-

2018 g

-

Screw Speed (rpm):

-

23 - 60 rpm

-

Screw diameter (mm):

-

85 mm

-

Screw L/D Ratio:

-

14

-

Weight (KG):

-

1000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

775 mm

-

Power (kW):

-

67 kW

-

Function:

-

greatly efficiency

-

Application:

-

Automation Machinery

-

Product name:

-

Assembly Line

-

Feature:

-

High speed and stability

-

After Warranty Service:

-

Video technical support;Online support;Spare parts

-

Certification:

-

CE, ISO9001

-

Product Keywords:

-

Production Equipment

-

Plastic injection moulding machine:

-

Customization

-

Usage:

-

Plastic product molding

-

Other Functions:

-

shoe sole injection molding machine

Quick Details

-

Plasticizing Capacity(g/s):

-

1000

-

Mold Height(mm):

-

5 - 100 mm

-

Ejector Stroke(mm):

-

225 mm

-

Ejector Force(kN):

-

152 kN

-

Theoretical Shot Volume(cm³):

-

2218 cm³

-

Injection Rate (g/s):

-

545.82 g/s

-

Injection Weight (g):

-

2018 g

-

Screw Speed (rpm):

-

23 - 60 rpm

-

Screw diameter (mm):

-

85 mm

-

Screw L/D Ratio:

-

14

-

Weight (KG):

-

1000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

775 mm

-

Power (kW):

-

67 kW

-

Function:

-

greatly efficiency

-

Application:

-

Automation Machinery

-

Product name:

-

Assembly Line

-

Feature:

-

High speed and stability

-

After Warranty Service:

-

Video technical support;Online support;Spare parts

-

Certification:

-

CE, ISO9001

-

Product Keywords:

-

Production Equipment

-

Plastic injection moulding machine:

-

Customization

-

Usage:

-

Plastic product molding

-

Other Functions:

-

shoe sole injection molding machine

Welcome to Tianluo Automation Machinery

Communication is important !

P ls feel free to contact us if there is any question !

Product Function

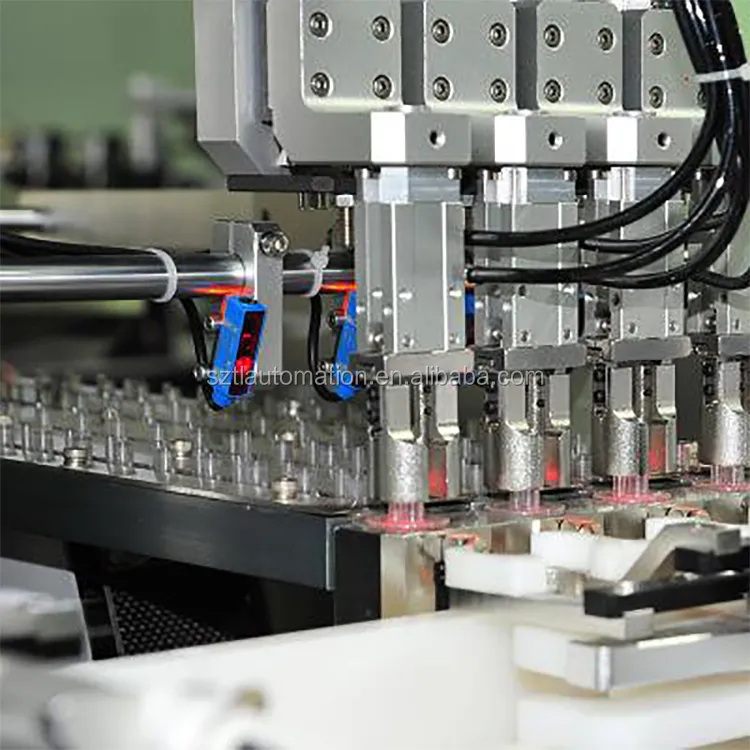

This equipment is suitable for the plastic products. It adopts PLC control system to automatically complete feeding, assembly and finished product discharge; it greatly improves production efficiency, reduces workers and reduces costs.

Machine Structure:

1. Electronic control: touch screen, PLC control;

2. Gas into components: cylinder drive, optical fiber sensor;

3. The vibrator automatic feeding;

4. The structure sliding part is made of high speed steel, which is stable wear and good fixity;

5. One year warranty;

6. Alarm indication;

Main Features:

1. This series machines is designed and manufactured specifically for the assembly industry.

2. Automatic feeding, assembly/one-time processing complete.

3. Automatic detection, automatic start when material is detected, automatic stop when lack of material.

4. Automatic counting , set output.

5. Using the touch screen, intuitive interface, simple and safe operation.

6. Abnormal shutdown, automatic alarming when reporting abnormal information.

Can be designed and customized for customers, to a greater extent to meet the technical needs of different products.